Method for preparing laminar assembled self-supporting membrane by using ion lift-off technology

A layered assembly and self-supporting technology, applied in coatings, devices for coating liquids on the surface, etc., can solve the problems that large-area self-supporting films cannot be prepared and are difficult to be widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

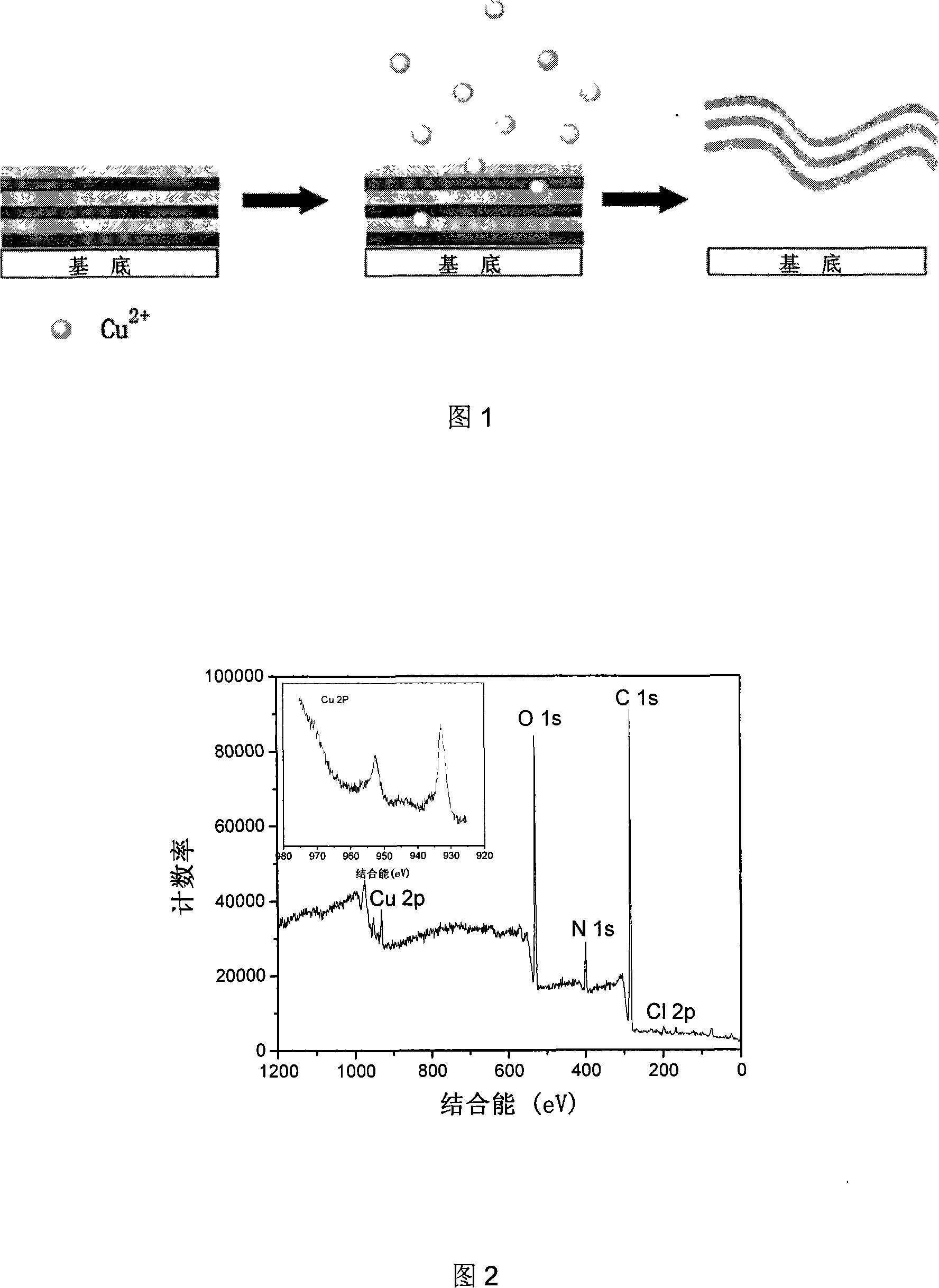

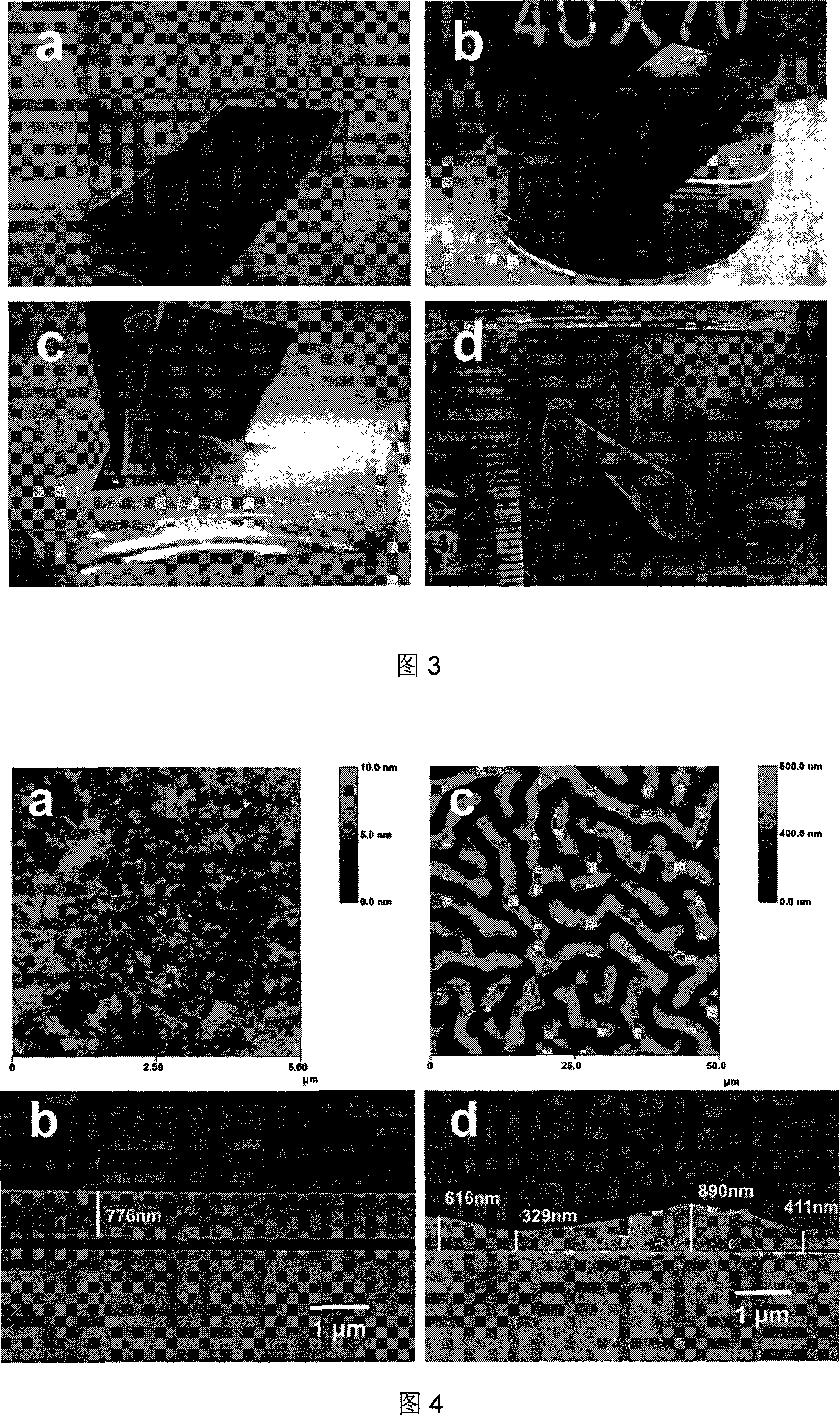

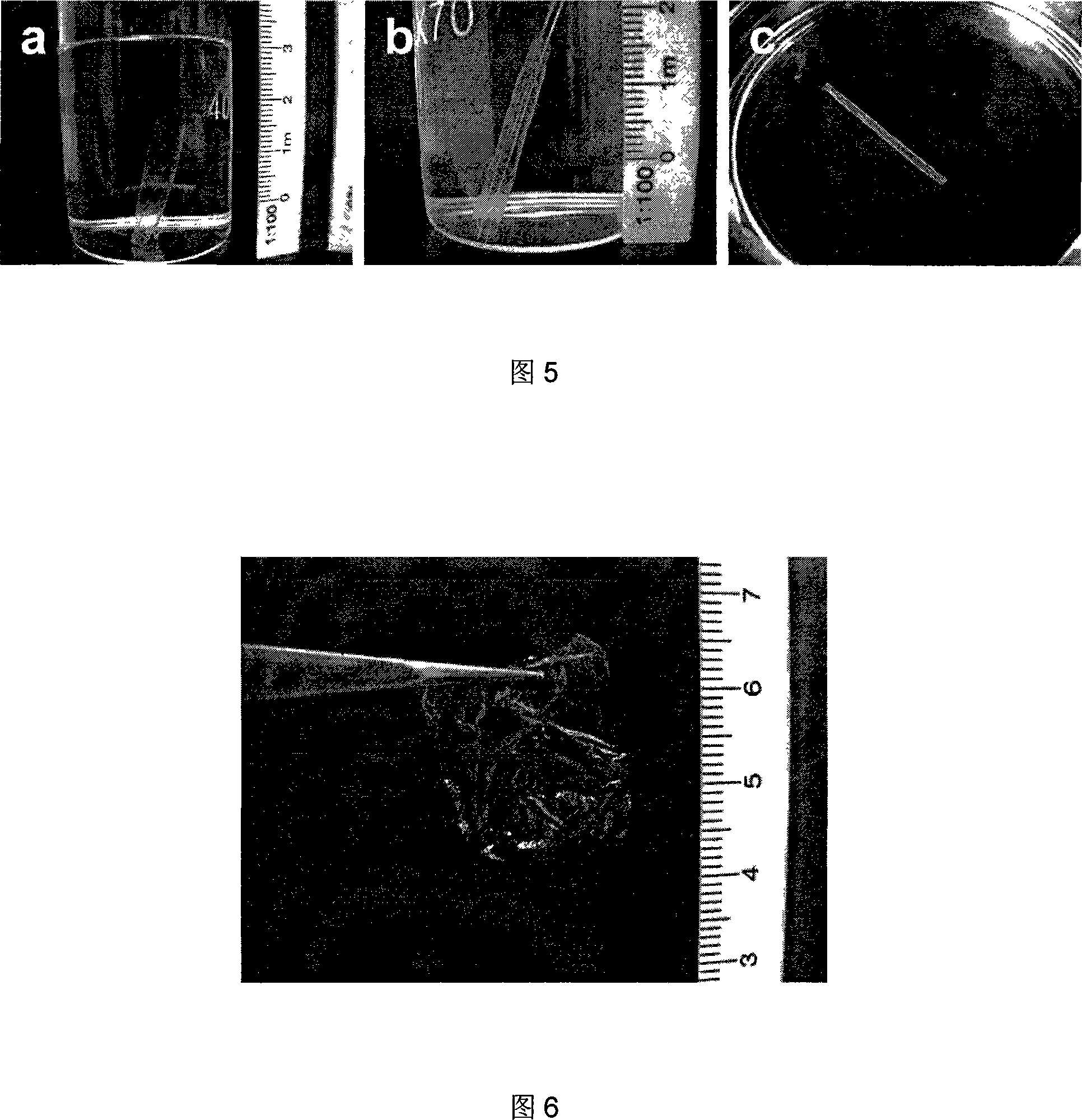

[0031] Embodiment 1: utilize Cu 2+ Preparation of polyacrylic acid (PAA) / polyacrylamine (PAH) layered self-supporting membrane

[0032] The selected solid substrate—the processing method of silicon (glass or quartz) substrate is as follows: successively use toluene, acetone, chloroform, ethanol and distilled water to treat ultrasonically for 10 minutes respectively, to remove various impurities attached to the surface of the substrate, and then in 98% H 2 SO 4 and 30%H 2 o 2 (v:v=7:3) in a mixed solution and heated to boil (~20min) until no bubbles overflowed. After cooling, rinse with a large amount of distilled water, then blow dry with nitrogen, and set aside, the surface of the treated silicon substrate contains a large amount of silanol; soak the treated silicon substrate in 1mg / mL polydiallyldimethylammonium hydrochloride Salt (PDDA) for 30min, the surface is modified by self-assembly with a layer of positively charged quaternized amino groups, and the modified subst...

Embodiment 2

[0039] Embodiment 2: utilize Fe 3+ Preparation of polyacrylic acid (PAA) / polyacrylamine (PAH) layered self-supporting membrane

[0040] The treatment of the substrate and the preparation of the PAA / PAH layered assembled polymer multilayer film are the same as the above example. Preparation method of PAA / PAH self-supporting membrane: stripping solution is 0.1mol / L FeCl 3 Aqueous solution, stripping ionic Fe 3+ It can also coordinate with the carboxyl group in PAA, which destroys the interaction between PAA and PDDA, and promotes the separation of the film from the substrate; at the same time, Fe 3+ Coordination with the carboxyl and amine groups in the film stabilizes the film, thereby allowing Fe 3+ Exfoliation of the layered assembled film yielded a self-supported layered assembled polymer multilayer film, and the self-supported polymer film exhibited the yellow color of ferric ions.

Embodiment 3

[0041] Example 3: Using H + Preparation of polyacrylic acid (PAA) / polyacrylamine (PAH) layered self-supporting membrane

[0042] Similarly, treat the substrate in the same way to prepare a PAA / PAH layered assembly polymer multilayer film, and prepare a cross-linked and stable PAA / PAH on the substrate by heat treatment (130-200°C, 0.5-3h). Layer-by-layer assembly of polymer multilayer films.

[0043] The preparation method of PAA / PAH self-supporting film: the (PAA / PAH) * 15 The layered assembled polymer multilayer film is soaked in the hydrochloric acid aqueous solution of pH = 2 for 3 minutes, and the PAA / PAH layered assembled self-supporting film can also be prepared. The preparation mechanism is: stripping the ion H + The protonation of PAA also achieves the effect of destroying the interaction between PAA and PDDA; at the same time, since the film has been stabilized by thermal crosslinking before the introduction of stripping ions, the stripping ion H + This covalently ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com