Heavy oil and residual oil combined treating process

A combined processing and residual oil technology, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment, can solve the problems of poor quality of solid petroleum coke, difficult to use and handle, reduce coke generation in equipment, etc., and improve the processing capacity and liquid yield, increased service life, and reduced severity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

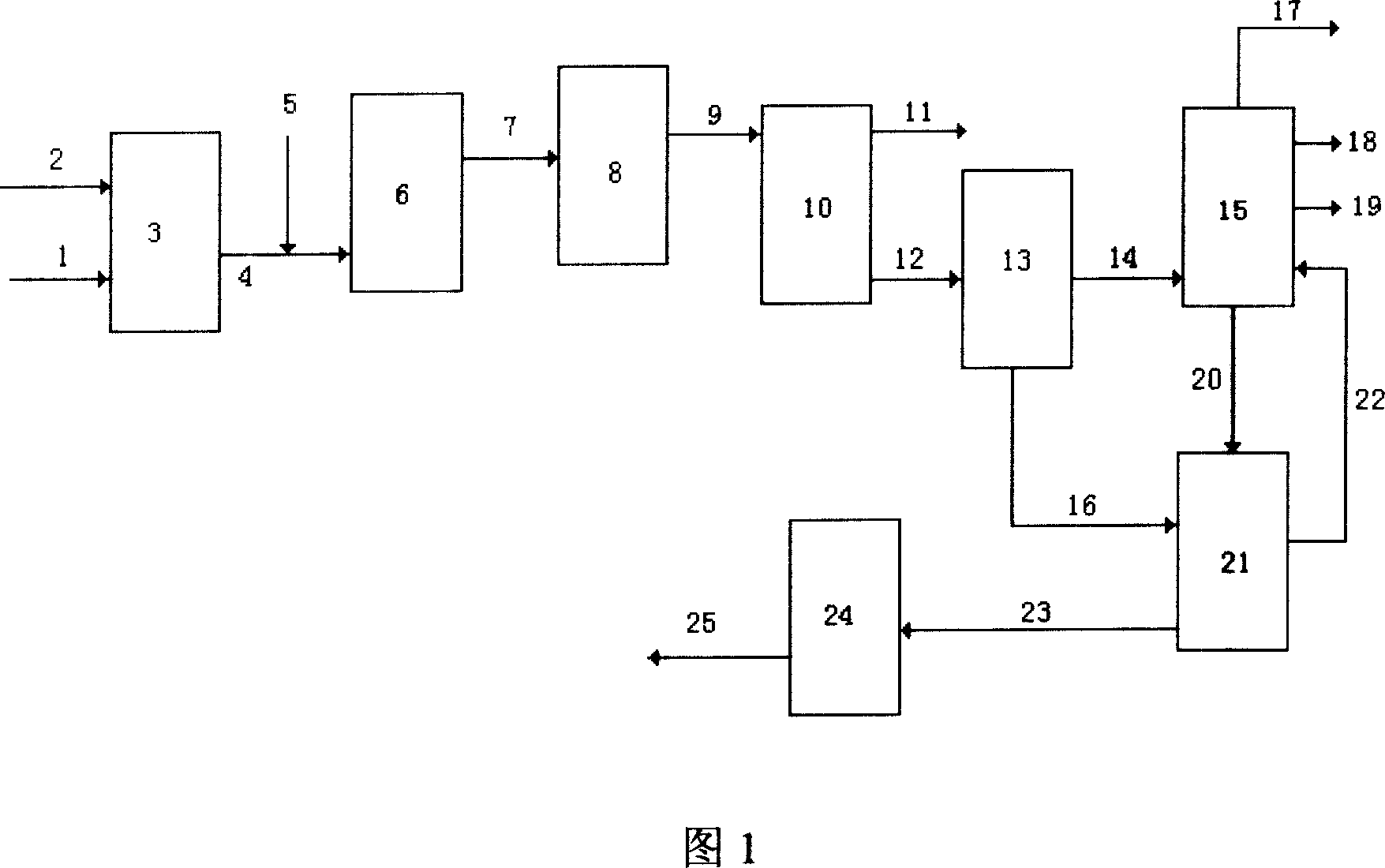

Image

Examples

Embodiment

[0028] The raw material oil used in the test is Tahe slag, and its raw material properties are shown in Table 1.

[0029] Table 1 Raw Oil Properties

[0030] project

nature

project

nature

Density (20℃), kg / m 3

1001

Ni

239.96

Viscosity(100℃)mm 2 .s -1

576.7

V

227.4

Carbon residue, wt%

18.3

Four components, wt%

Saturation

29.0

C

85.31

33.1

H

9.89

24.5

S

3.36

asphaltenes

13.4

N

1.42

Distillation range, wt%

Metal content, μg / g

350℃~500℃

32.1

Fe

13.65

>500℃

67.9

[0031] It can be seen from the properties of the raw material that the raw material is low-quality crude oil with high sulfur, high metal, and high carbon residue. The raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com