Overhead reverse slide conveying system

A conveying system and skateboard technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as noise pollution and oil pollution, and achieve the effect of reducing friction noise, avoiding oil pollution and reducing noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0020] In conjunction with accompanying drawing, provide specific embodiment of the present invention as follows:

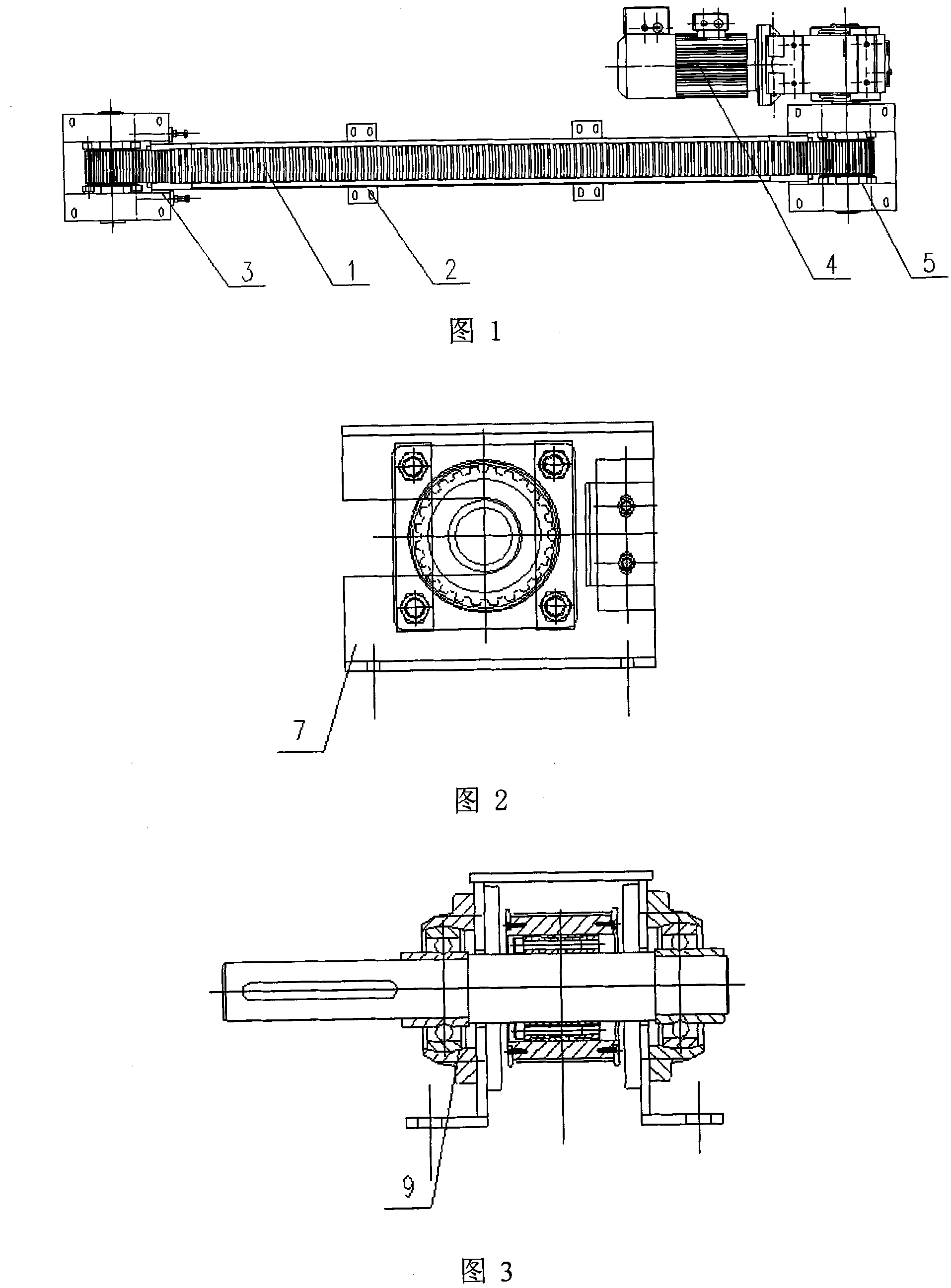

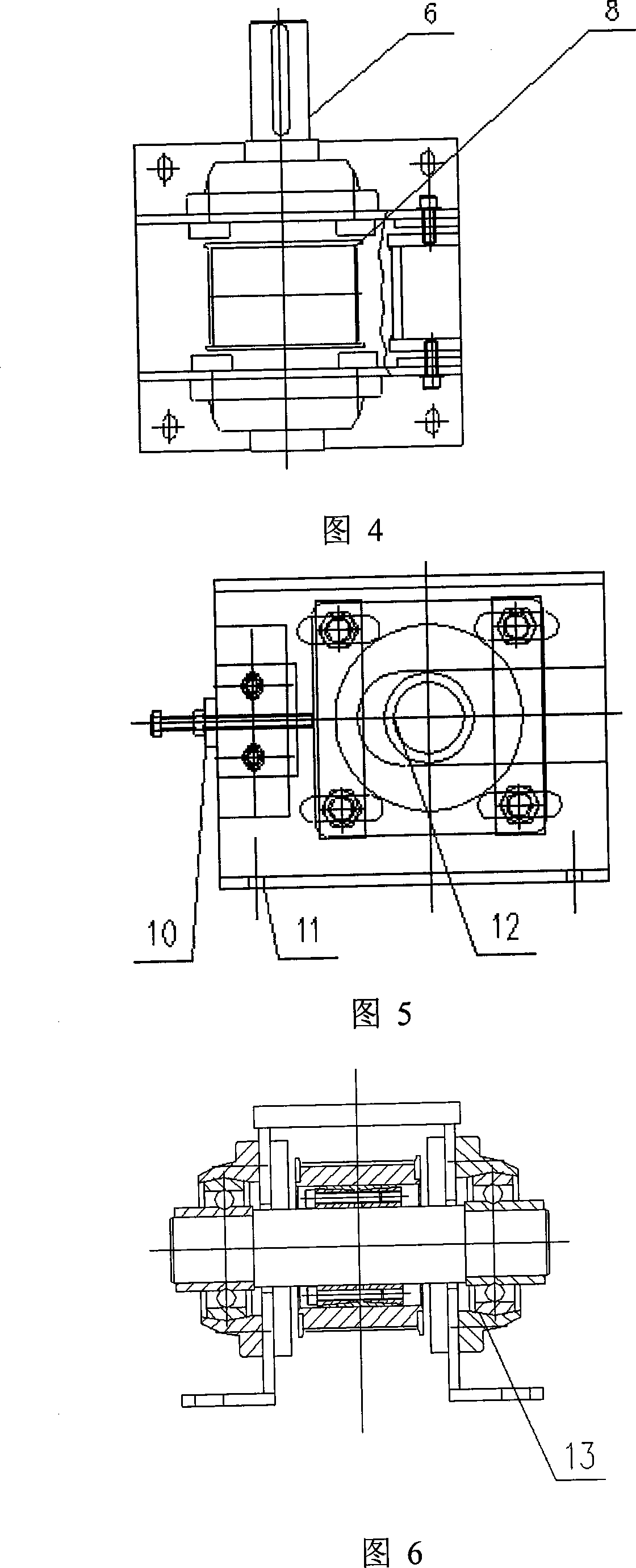

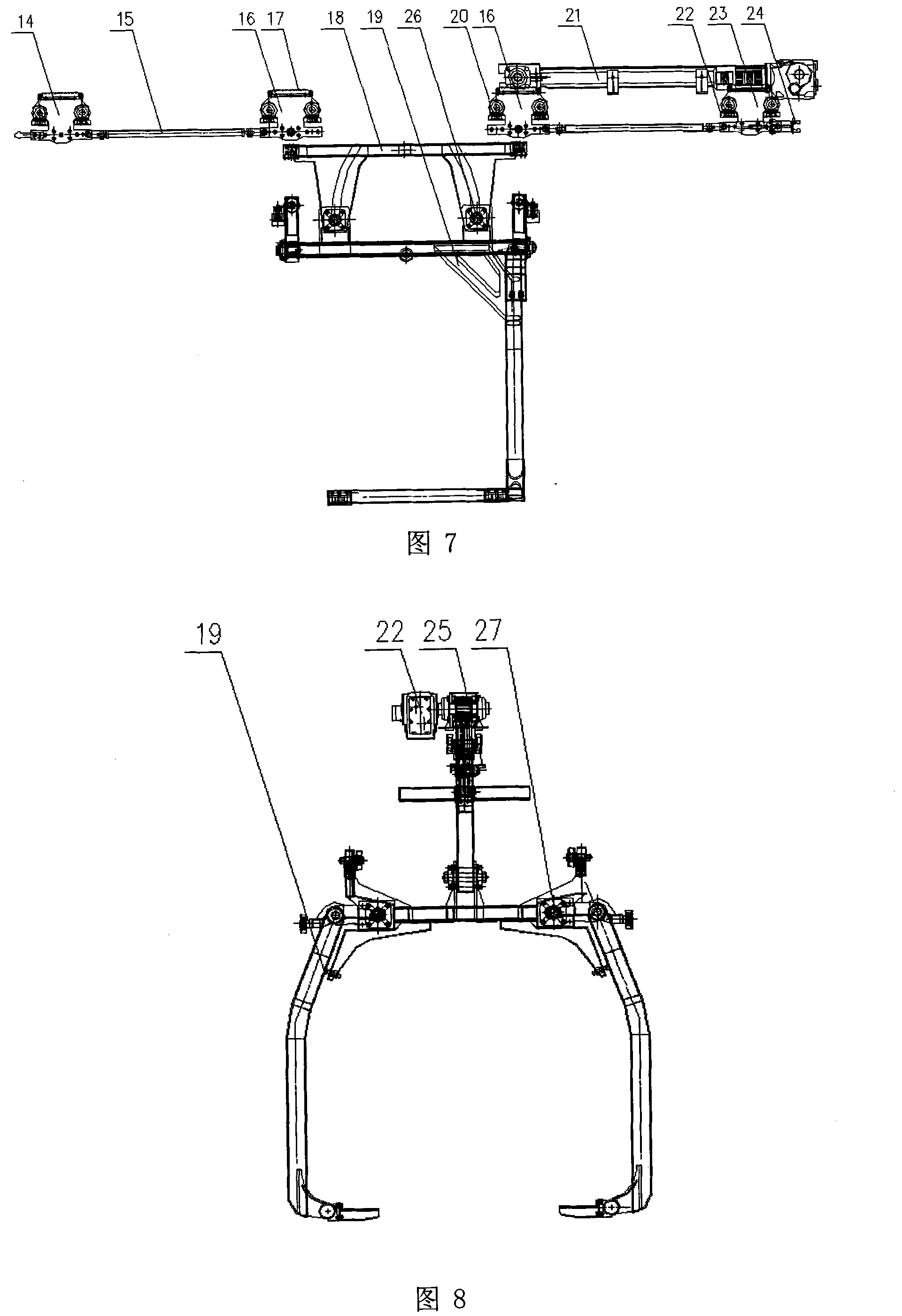

[0021] The present invention is mainly composed of a driving mechanism, a spreader train set, a nozzle, a track body and a turnout unit. As shown in Figure 1-6:

[0022] The driving mechanism described in this embodiment is composed of a double-sided synchronous toothed belt 1 , a supporting frame 2 , a tensioning assembly 3 , a driving motor 4 and a driving assembly 5 . The double-sided synchronous toothed belt 1 is mated with modified MC nylon. It is a double-sided toothed belt structure with a tooth pitch of 20 mm, a tooth profile error of 0.13 mm, and a backlash of 0.2 mm. The toothed surface on one side is meshed with the synchronous pulley 8 on the drive belt assembly 5, and the toothed surface on the other side is meshed with the toothed plate on the spreader train set. The double-sided synchronous toothed belt 1 is installed above the track by the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com