Side-wise rotary type automatic ejection pick-up head

An automatic pop-up, camera technology, applied in the direction of image communication, color TV parts, TV system parts, etc., can solve problems such as easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

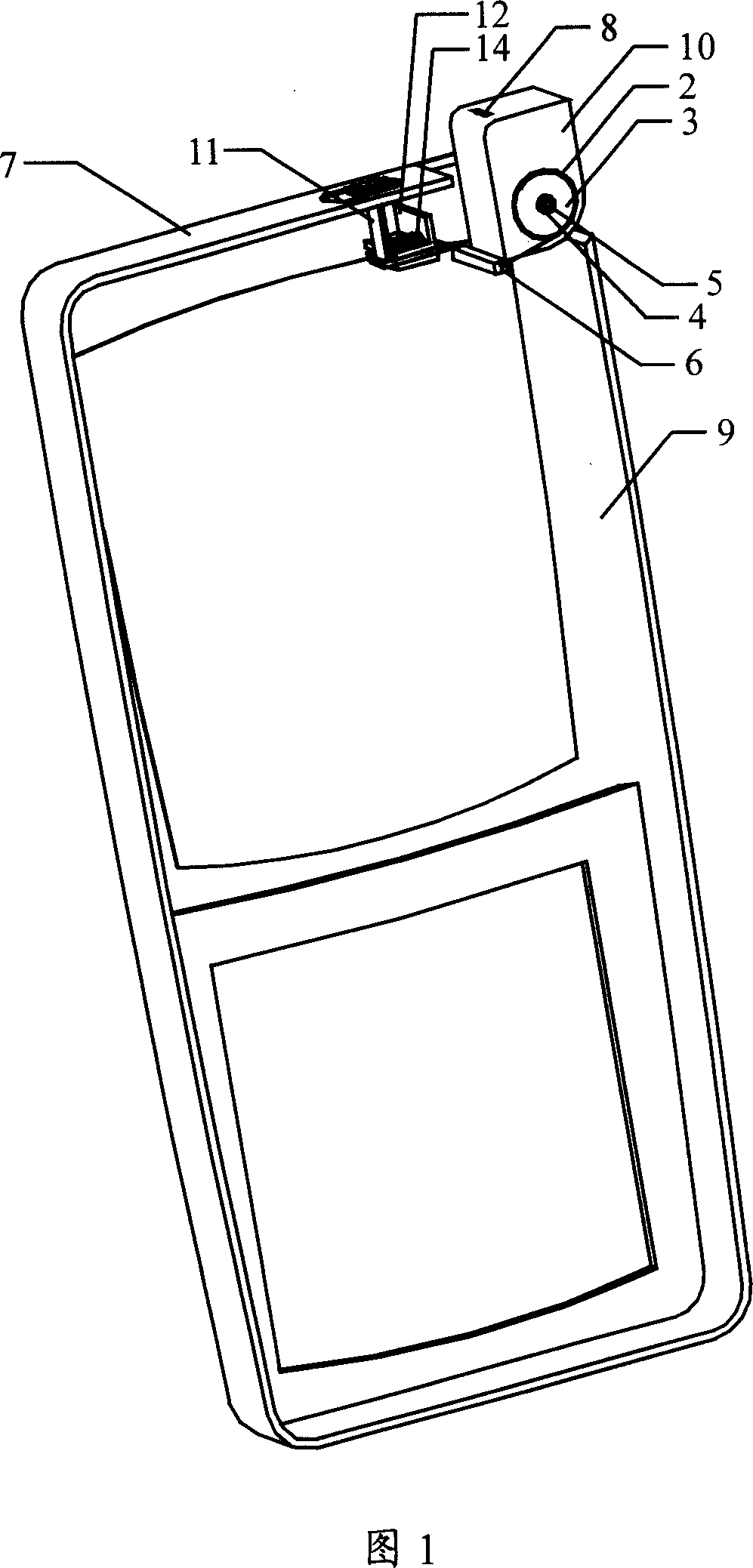

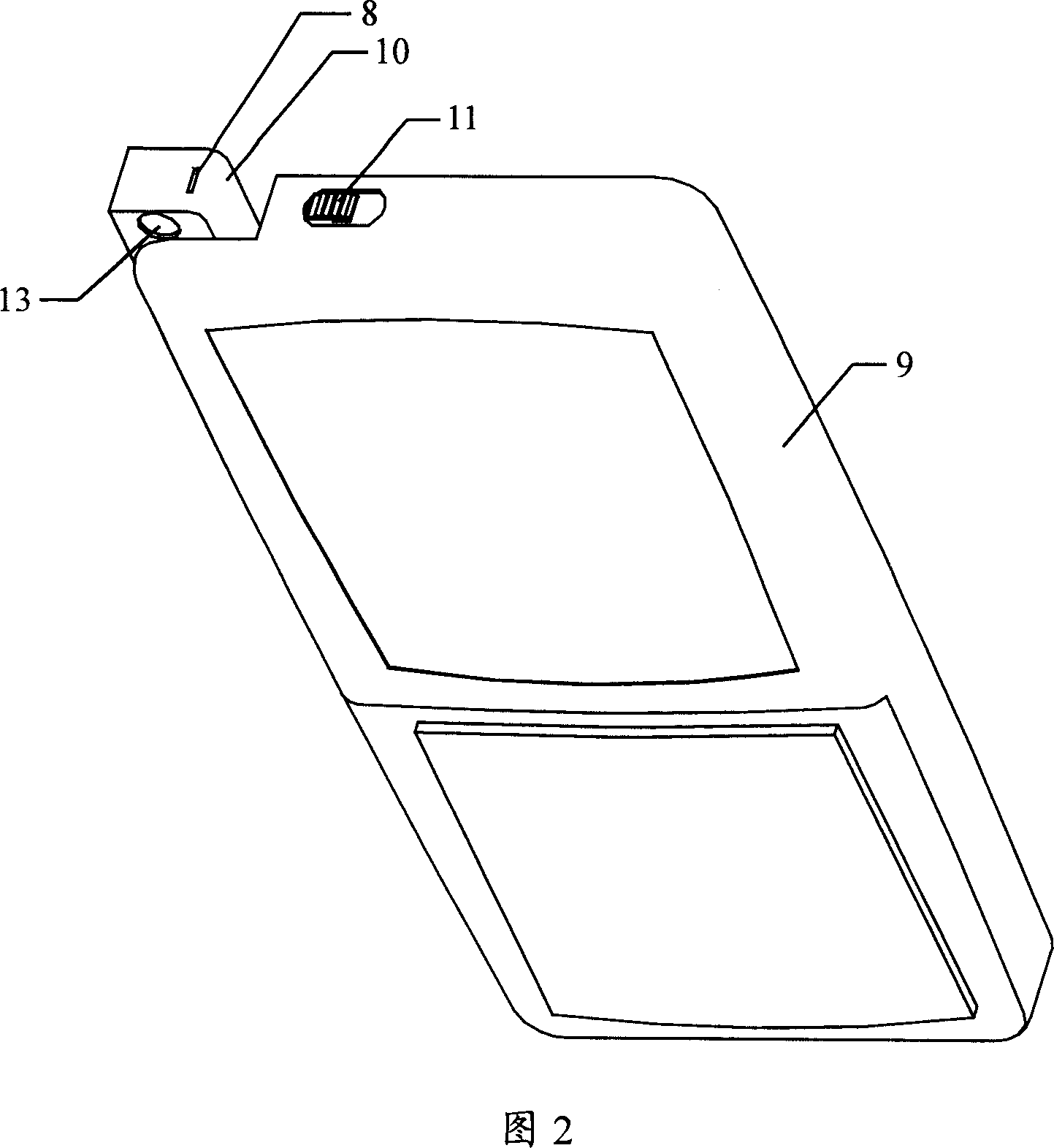

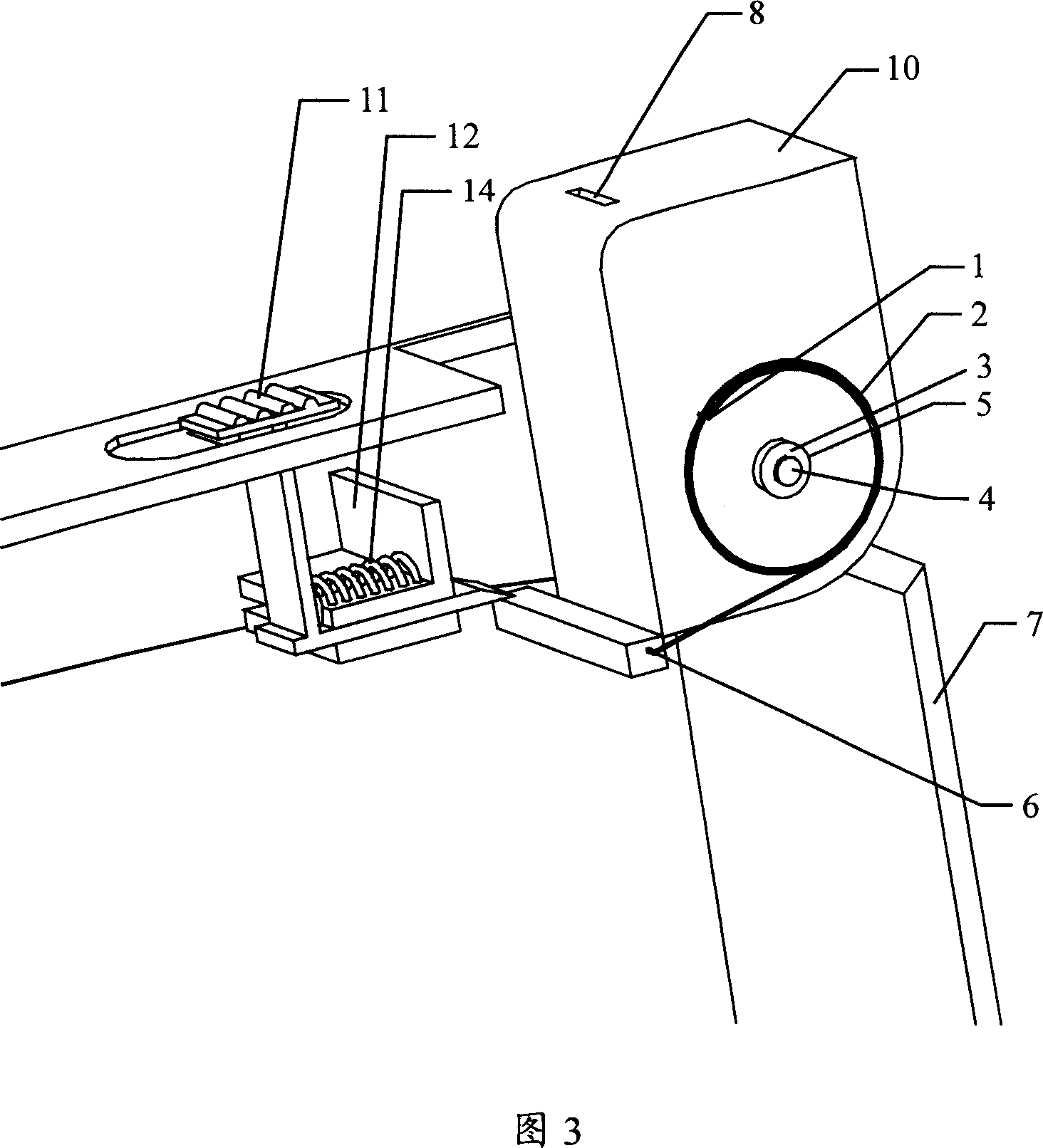

[0021] See attached drawings 1-5.

[0022] Described mobile terminal uses the camera head of lateral rotation type automatic pop-up to contain:

[0023] The camera 10 is rotatably connected to the casing 7. In the reset state of the camera, the camera 10 is installed in the protective cavity above the casing 7; in the working state, it rotates sideways and ejects;

[0024] Working spring 2, two ends are respectively connected on camera 10 and casing 7, when camera 10 is in reset state, working spring 2 is in stretched state, when camera 10 is in working state, working spring 2 is in stretched state;

[0025] The guide rail 12 is composed of two parallel sub-rails and is fixed on the casing 7;

[0026] Trigger key 11, when the camera 10 is in the reset state, the trigger key 11 locks the camera 10 under the guidance of the guide rail 12; when the camera 10 is in a working state, the trigger key 11 releases the camera 10;

[0027] The return spring 14 is connected to the trigg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com