Drum washing machine with drying function

A drum washing machine and washing machine technology, applied in the field of drum washing machines, can solve the problems of high waste costs, large volume, and increased overall product size of motors and electronic products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

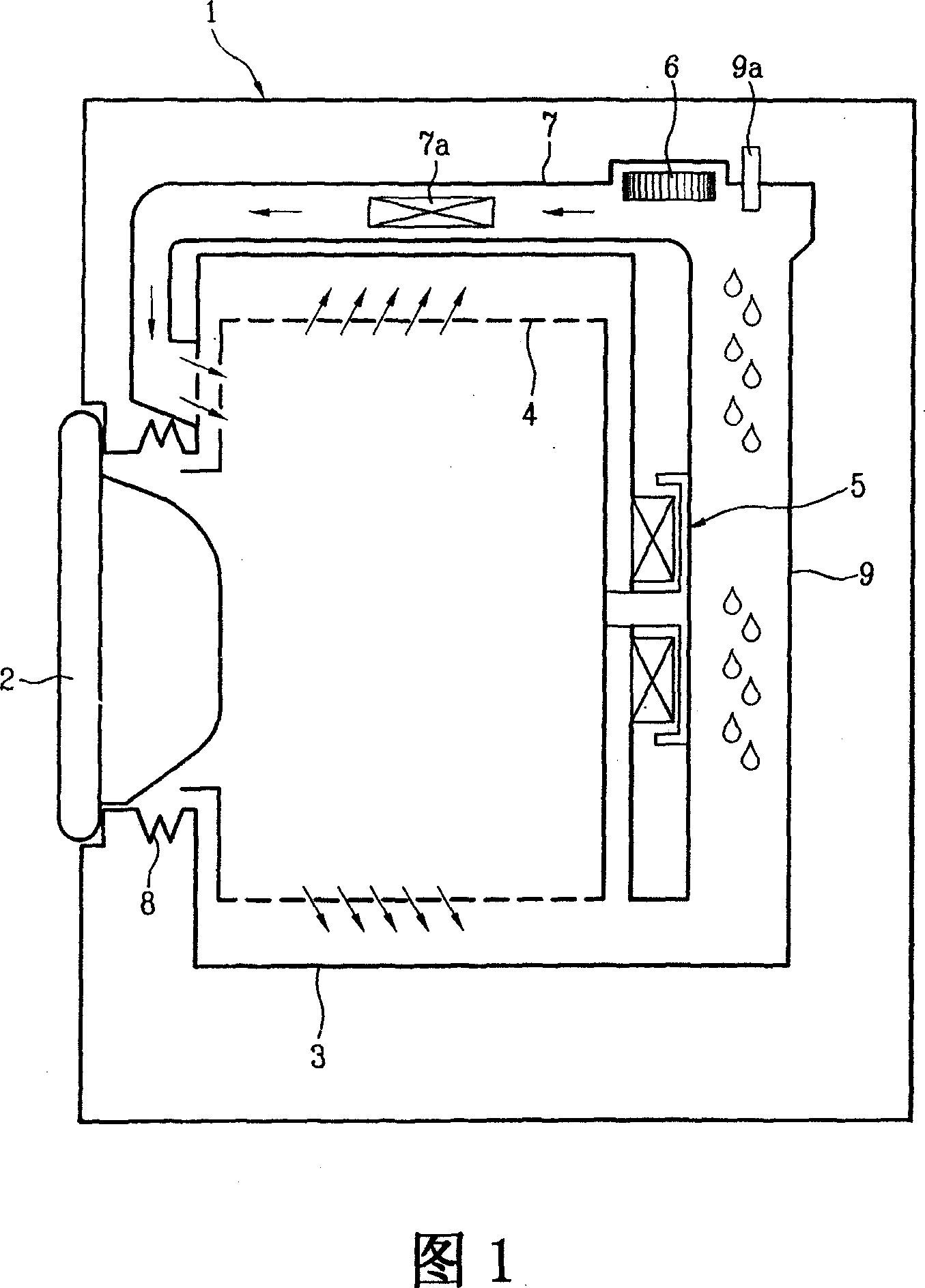

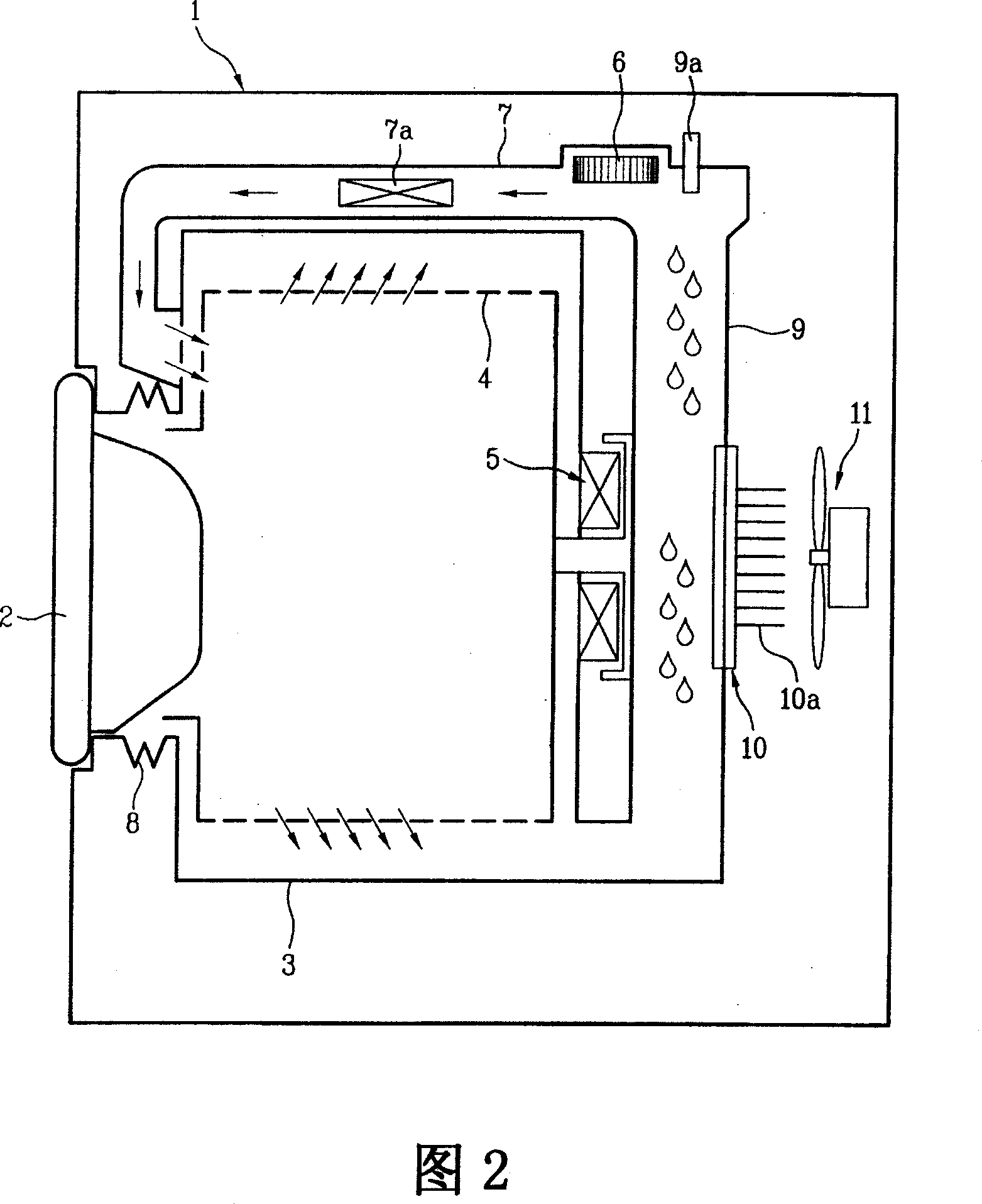

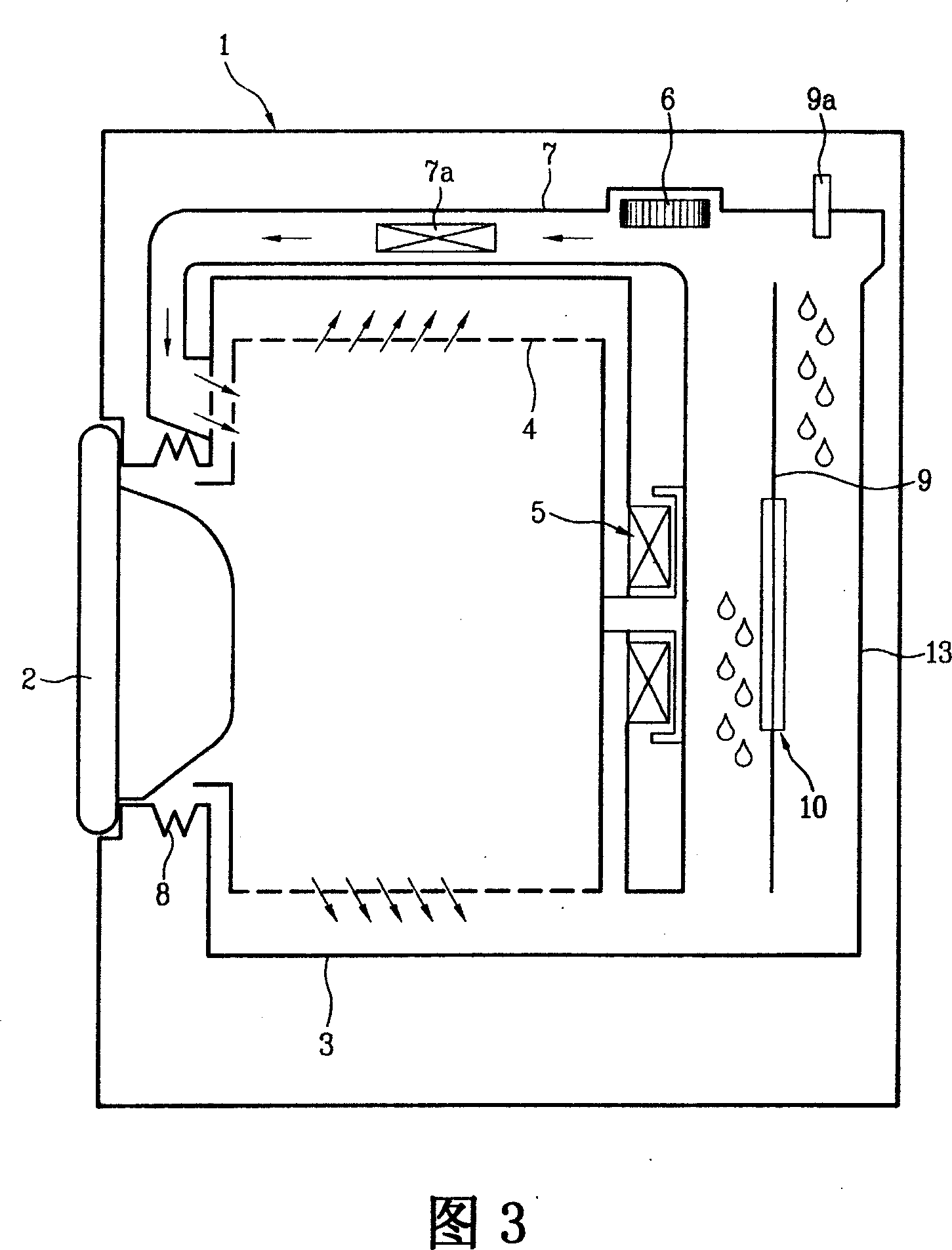

[0046] As shown in Figure 2, the drum washing machine with drying function in the first embodiment of the present invention includes the following parts: a washing bucket 3 installed inside the shell 1 forming the appearance and used to accommodate washing water; A drum 4 rotatably installed in the above-mentioned washing bucket; a motor 5 for transmitting driving force to the above-mentioned drum; forming an air circulation flow path, so that the air discharged from the above-mentioned drum flows into the circulation air duct of the above-mentioned drum; The thermoelectric module 10 condenses and removes moisture contained in the humid air discharged from the above-mentioned drum.

[0047] Wherein, the above-mentioned thermoelectric module 10 is composed of a thermoelectric device that absorbs or releases heat at the above-mentioned junction according to the directionality of the current flowing on the junction of two different metals; and, preferably, the above-mentioned ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com