Method for measuring optical film absorption loss

An optical thin film and laser technology, which is applied in the direction of testing optical properties, measuring devices, and optical instrument testing, to achieve good stability, improve sensitivity, and reduce measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

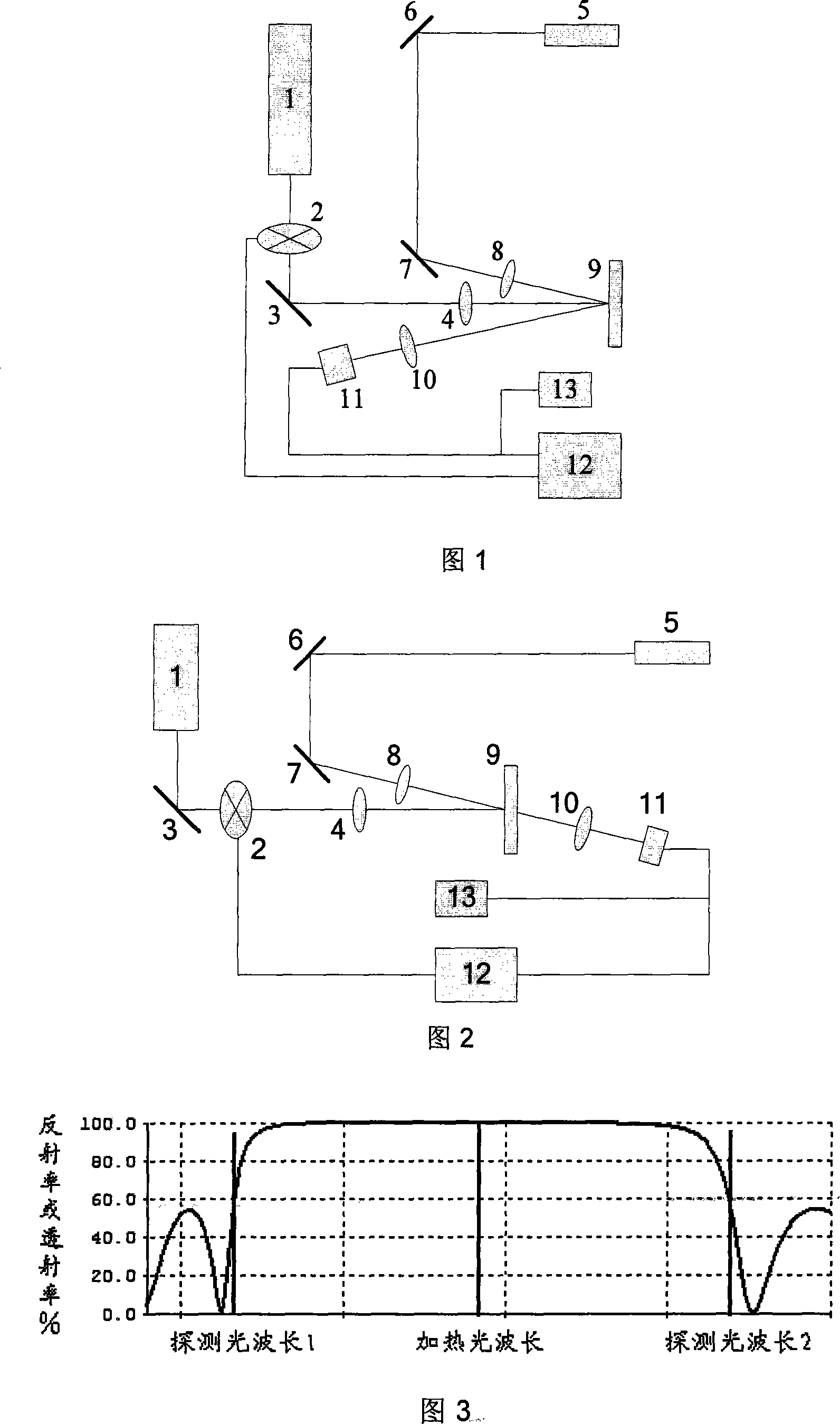

[0017] As shown in Figures 1 and 2, the measuring device for implementing the method of the present invention can be a reflective measuring device or a transmissive measuring device, consisting of a heating laser light source 1, a chopper or an acousto-optic modulator 2, a mirror 3, 6 and 7 , Lenses 4, 8 and 10, detection laser light source 5, optical film sample to be tested 9, detector 11, lock-in amplifier 12, and digital oscilloscope 13.

[0018] The specific implementation of the method of the present invention is as follows: the output beam of the heating laser light source 1 is intensity-modulated by an optical chopper or acousto-optic modulator or electro-optic modulator 2 (modulation frequency range 1Hz 1MHz, pulsed laser does not pass through the modulator) and then reflected The reflection of the mirror 3 changes the direction and the lens 4 focuses on the surface of the optical film element 9 under test, and the output signal of the chopper 2 is connected to the lock-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com