Method for manufacturing semiconductor package structure having micro electro-mechanical system

A micro-electro-mechanical system and packaging structure technology, which is applied in semiconductor/solid-state device manufacturing, microstructure technology, semiconductor devices, etc., can solve problems such as high difficulty and increased production costs, and achieve reduced production costs, increased production, and application broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

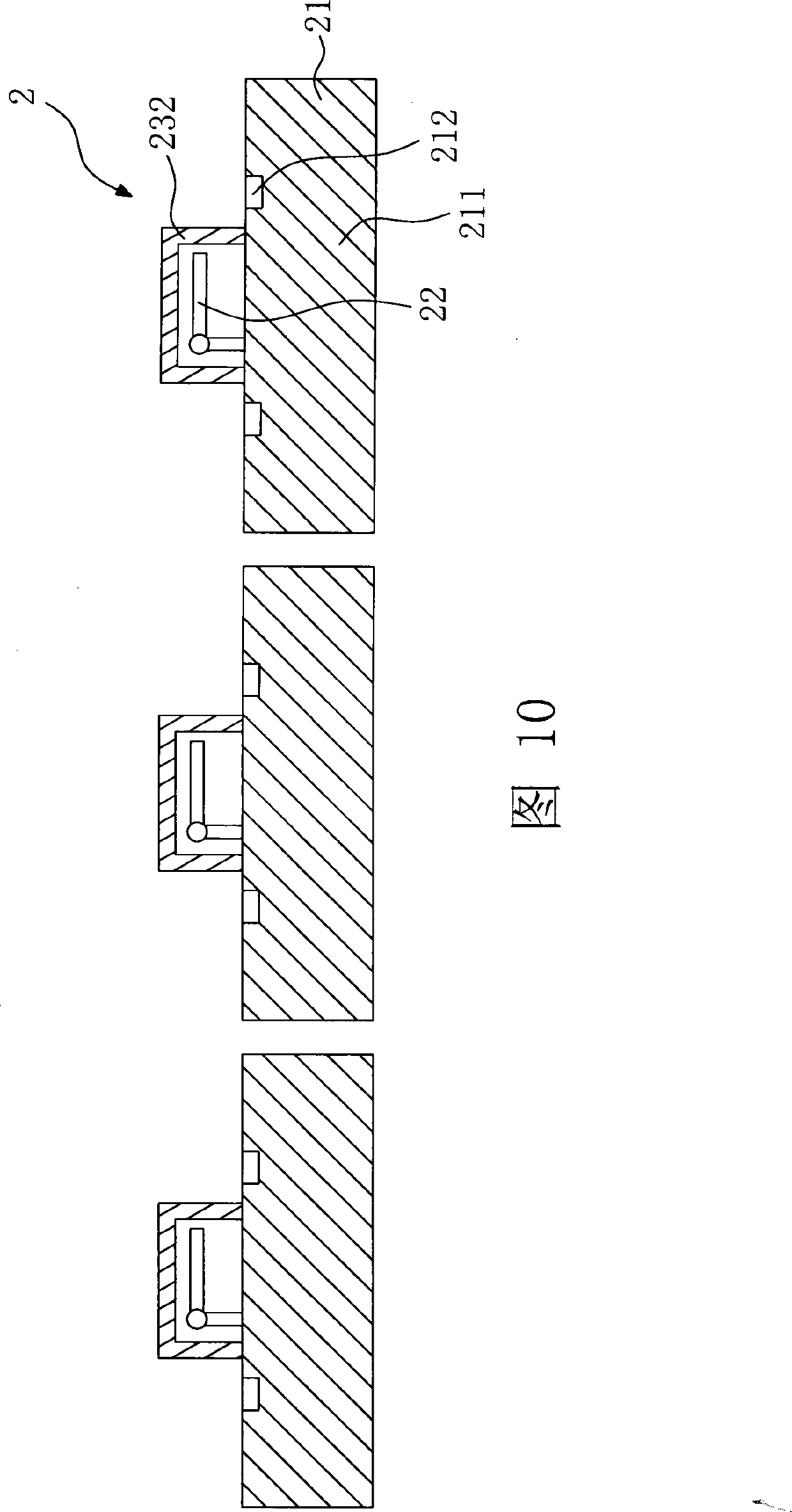

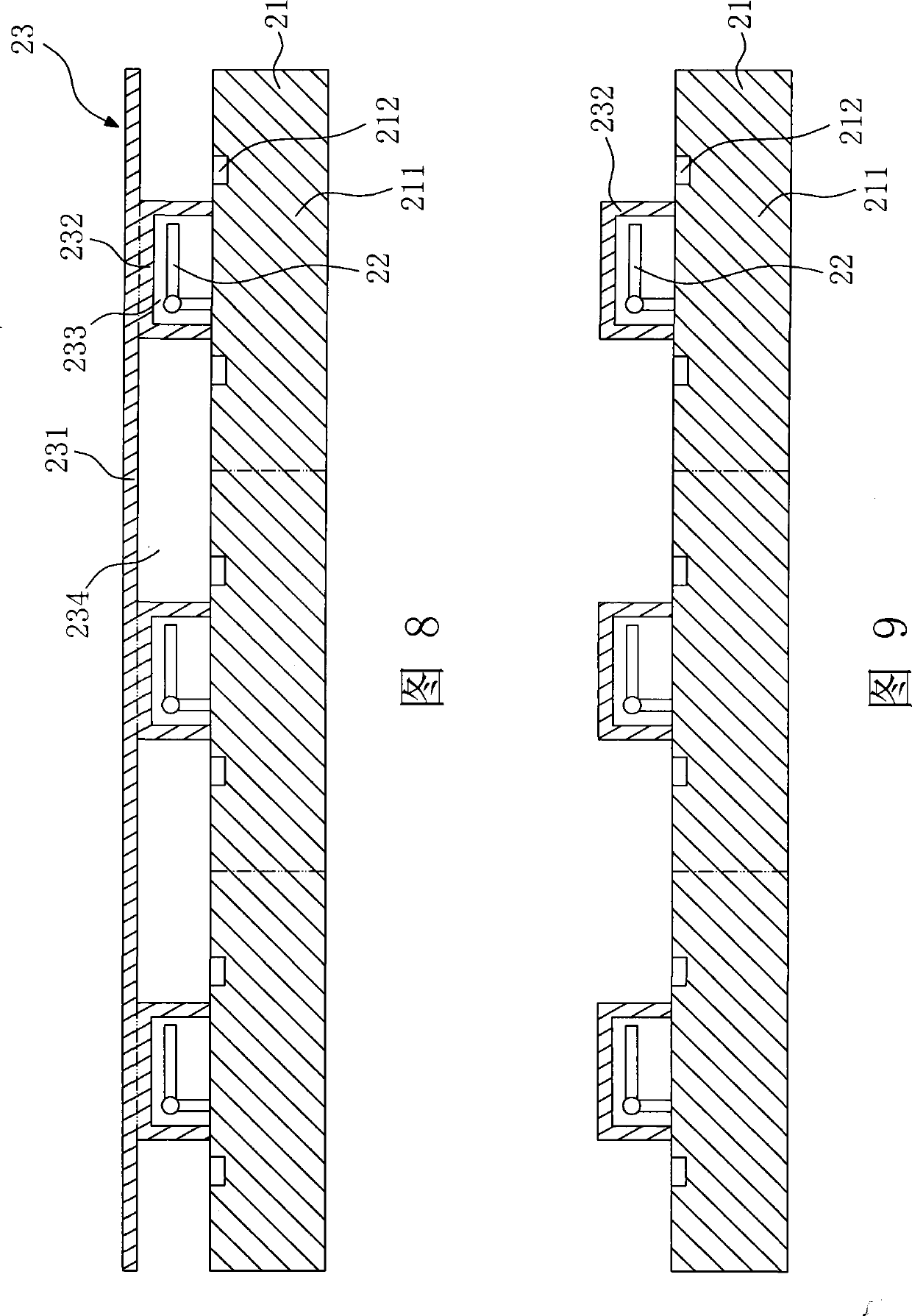

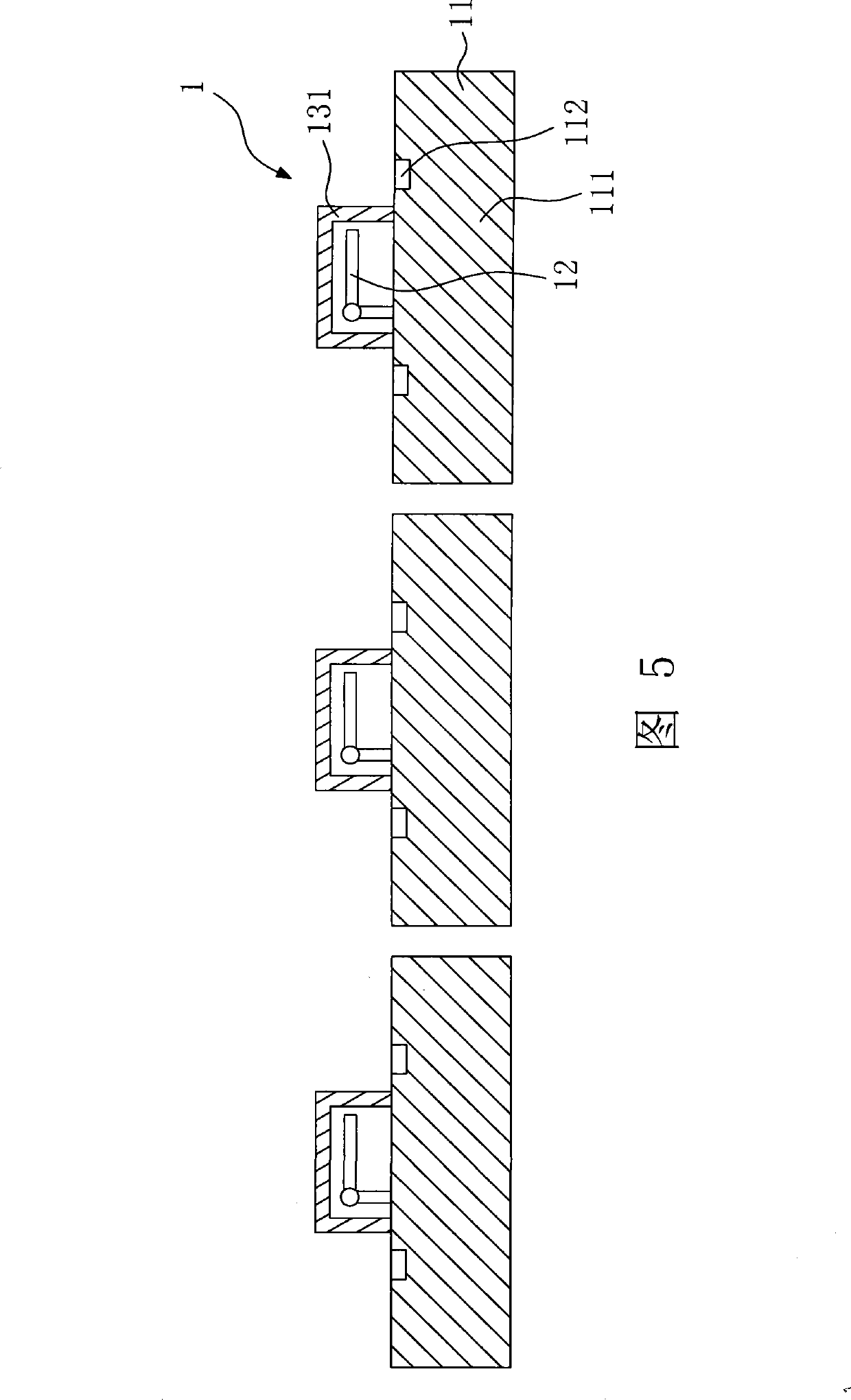

[0018] Refer to Figure 6 to Figure 10 , which shows a schematic diagram of the manufacturing method of the semiconductor package structure with Micro-Electro-Mechanical Systems (MEMS) of the present invention. first reference Image 6, A substrate 21 is provided, and the substrate 21 has a plurality of substrate units 211 (shown by dotted lines), and each substrate unit 211 has a plurality of pads 212 . The substrate 21 can be a CMOS wafer.

[0019] refer to Figure 7 , disposing a MEMS 22 on each substrate unit 211 . In this embodiment, the MEMS 22 is an optical element. The MEMS 22 includes at least one microlens set 221 , and each of the microlens sets 221 includes: a support member 222 , a hinge 223 and a microlens 224 . The support member 222 has a first end 225 and a second end 226 , wherein the second end 226 of the support member 222 is located on the substrate unit 211 . The hinge 223 is disposed on the first end 225 of the support member 222 . One end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com