Oxygen iodine laser without dilution gas

A gas-oxygen-iodine chemistry and laser technology, applied in lasers, laser parts, laser parts, etc., can solve the problems of reducing the volume and weight of low-temperature molecular sieve adsorption pumps, and achieve the effect of reducing operating costs and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

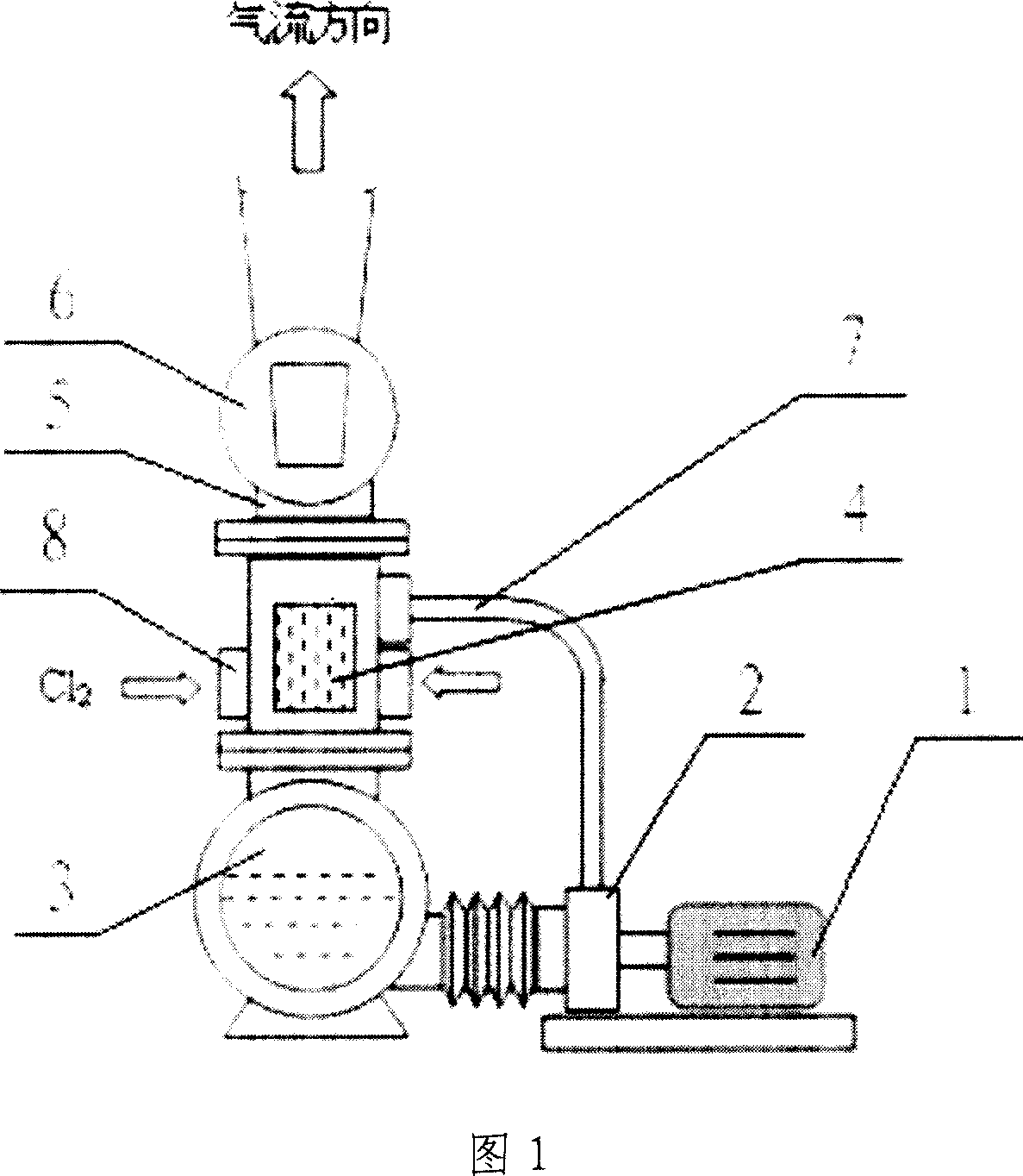

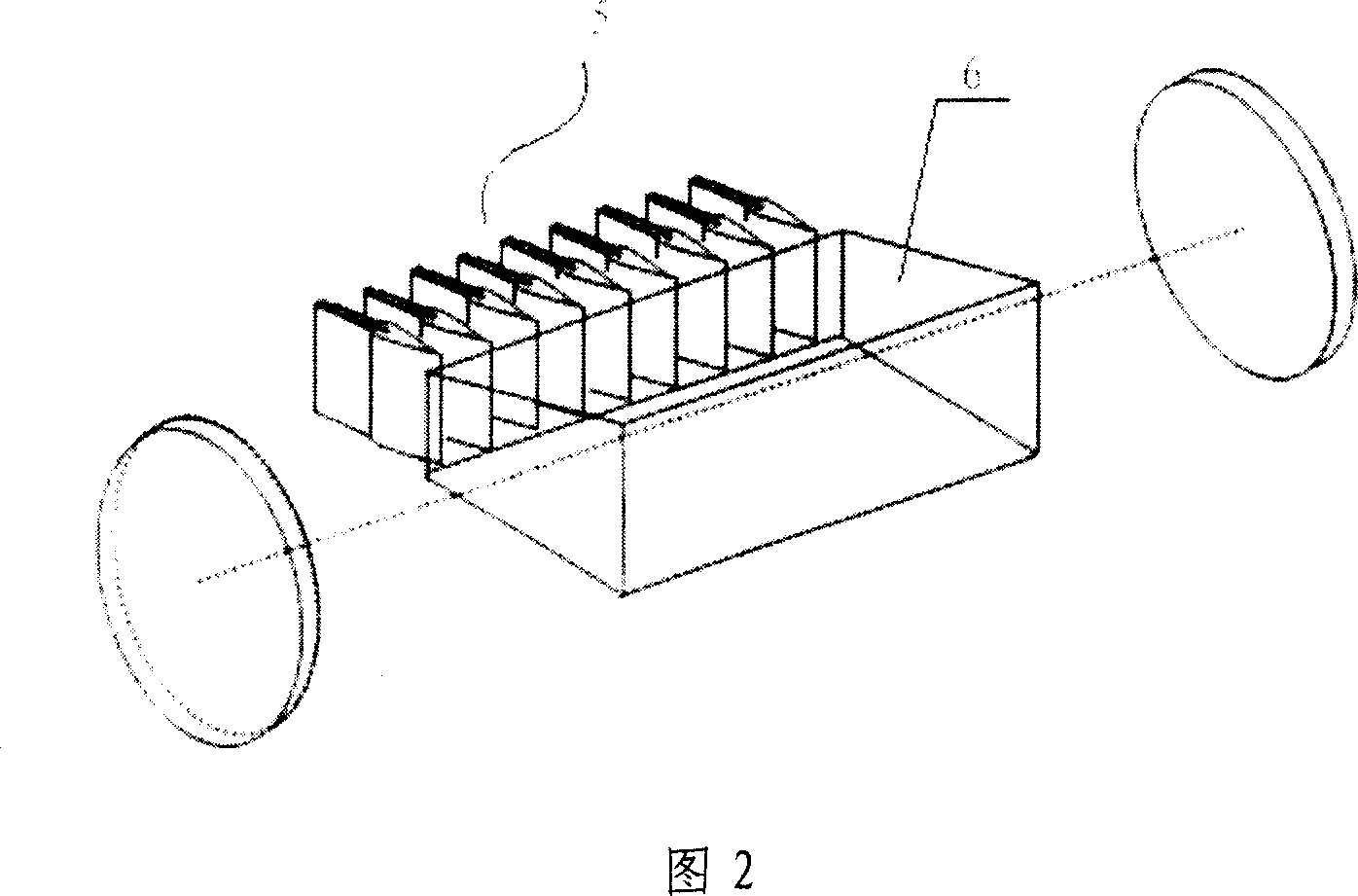

[0019] As shown in Figure 1, the present invention comprises motor 1, BHP liquid circulation pump 2, BHP liquid collection tank 3, singlet oxygen generator 4, nozzle assembly 5 and light chamber 6, BHP liquid circulation pump 2 and BHP liquid collection The tanks 3 are connected, and a singlet oxygen generator 4 is arranged above the BHP liquid collection tank 3. The BHP liquid circulation pump 2 communicates with the singlet oxygen generator 4 through a connecting pipe 7, and the singlet oxygen generator 4 is opened. There is a chlorine gas inlet hole 8; the nozzle assembly 5 is located above the singlet oxygen generator 4 and communicated with the singlet oxygen generator 4, and an optical chamber 6 communicating with the nozzle assembly 5 is provided above the nozzle assembly 5. The oxygen-iodine chemical laser has a vertical structure, that is, the upper outlet of the singlet oxygen generator 4 is directly connected to the nozzle assembly 5, and the length of the transition...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is: the distance between two rows of iodine spray 12 and the nozzle throat 11 is respectively 4mm and 2mm, and the average distance X1 between the two rows of iodine spray 12 and the nozzle throat 11 The design Mach number of the nozzle is 2.2, correspondingly, the throat width X2 of each unit of the nozzle is 4mm, and the width X3 of the nozzle outlet is 10mm.

[0026] The design gas-liquid reaction specific surface area of singlet oxygen generator 4 is 4cm -1 , the average gas-liquid reaction zone length X4 along the airflow direction is 8cm, and the chlorine gas flux per unit cross section is 2.8mmol / s.cm 2 .

Embodiment 3

[0028] The present embodiment is different from Embodiment 1 in that: the distance between the two rows of iodine nozzles 12 and the nozzle throat 11 is respectively 6mm and 4mm, and the average distance X1 between the two rows of iodine nozzles 12 and the nozzle throat 11 The design Mach number of the nozzle is 2.8, the corresponding throat width X2 of each unit of the nozzle is 6mm, and the width X3 of the nozzle outlet is 15mm.

[0029] The design gas-liquid reaction specific surface area of singlet oxygen generator 4 is 6cm -1 , the average gas-liquid reaction zone length X4 along the airflow direction is 12cm, and the chlorine flux per unit cross section is 2.8mmol / s.cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com