Reciprocating type pumping rod centralizer friction and wear test machine

A friction and wear test, centralizer technology, applied in the testing of machine/structural components, instruments, mechanical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

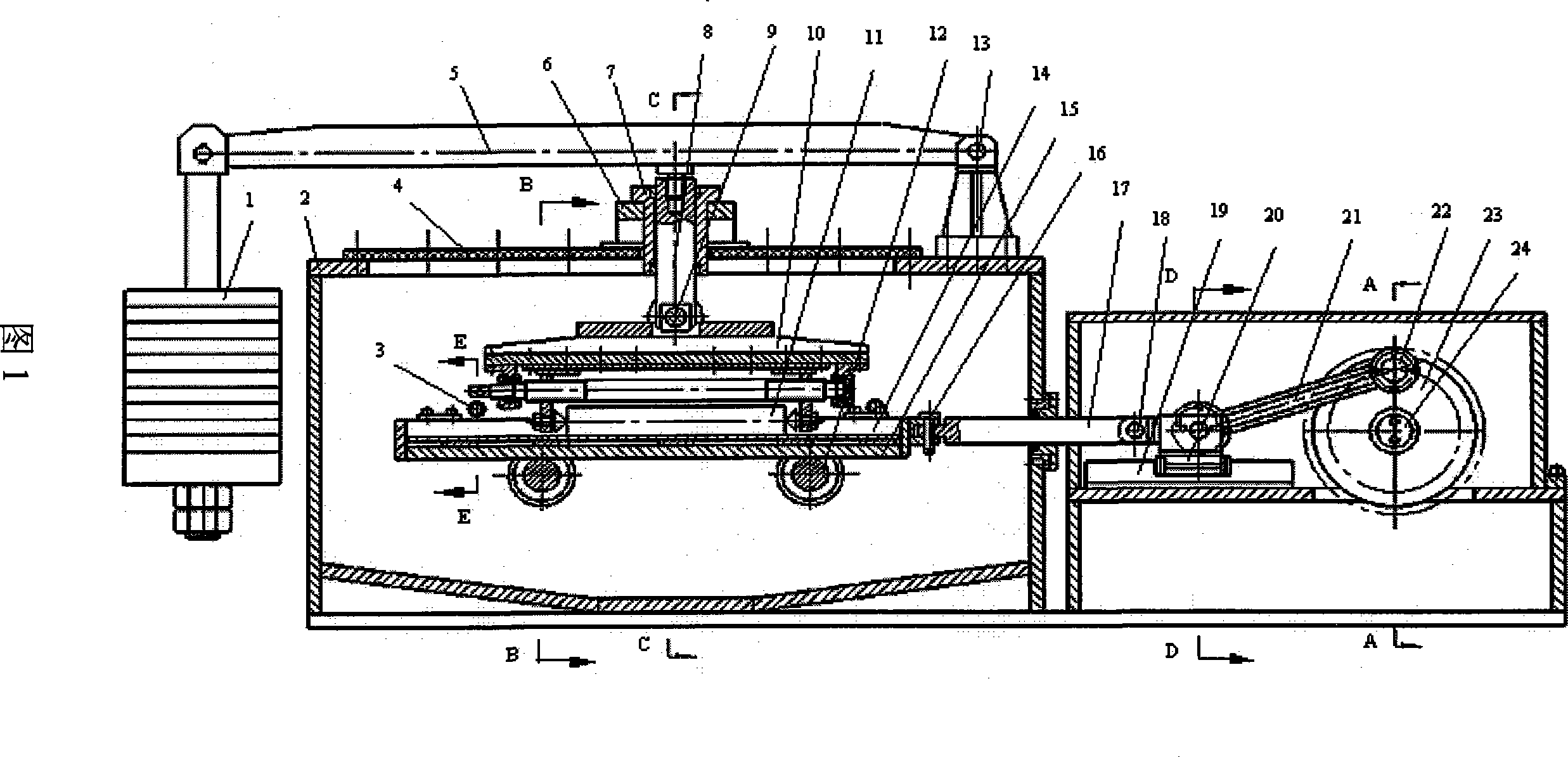

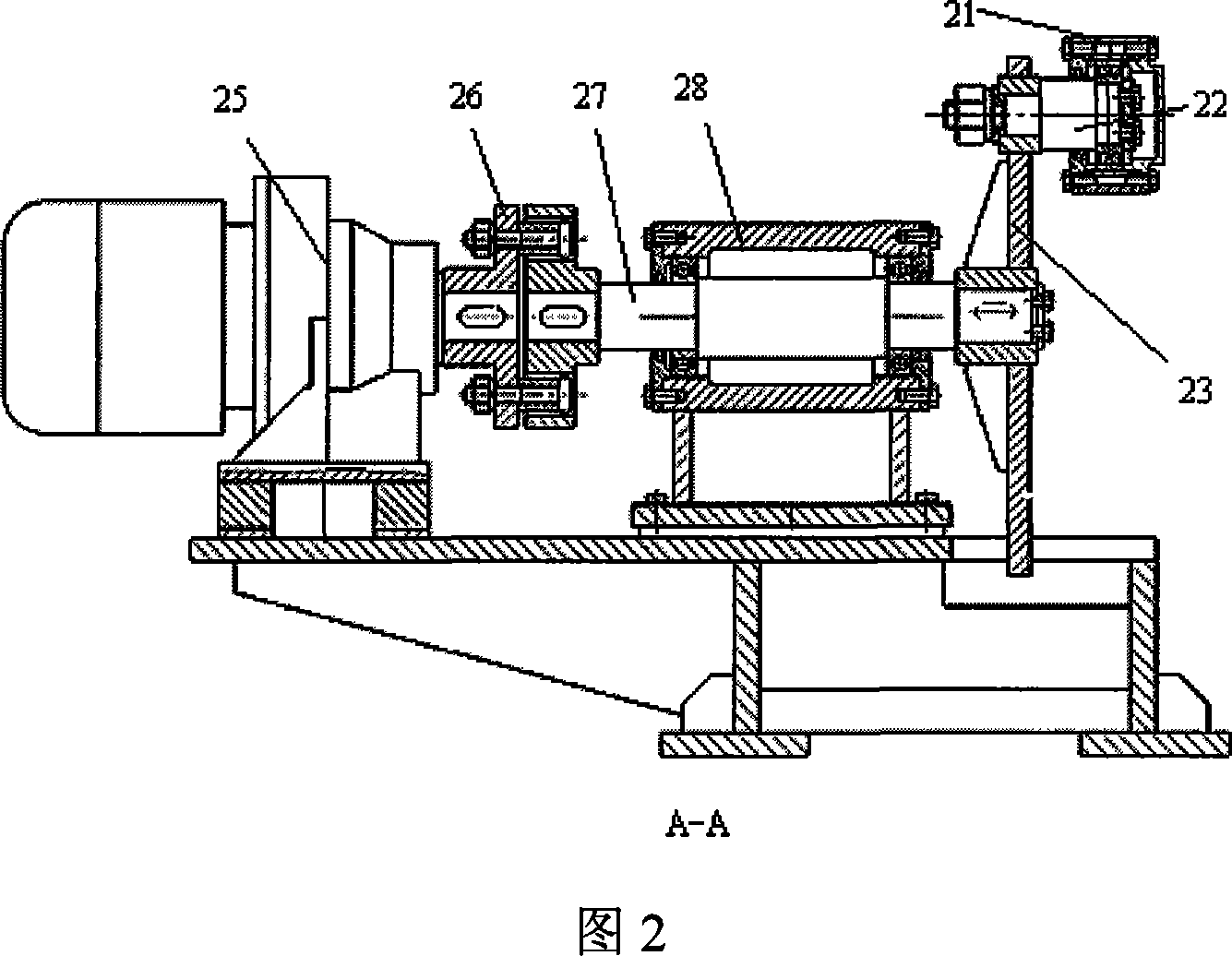

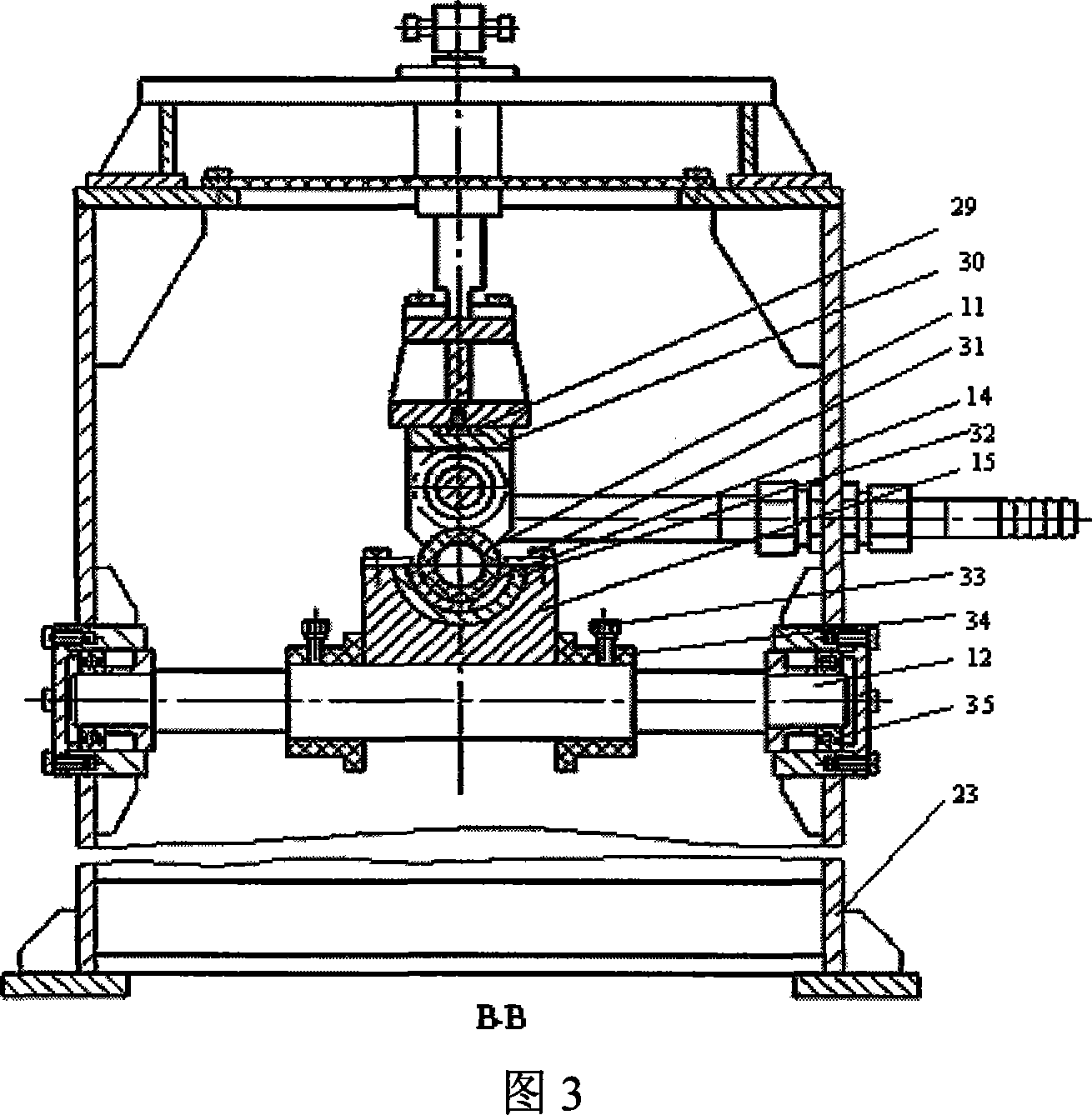

[0021] As shown in Fig. 1, it is an embodiment disclosed by the present invention. The power unit is driven by the motor cycloid reducer 25 through the shaft coupling 26, the transmission shaft 27, and the eccentric wheel 23 rotates, and the eccentric wheel 23 drives the connecting rod 21 through the crank pin 22 for plane movement (see Figure 2). The other end of the connecting rod 21 is connected with a guide block connector 20 to make it move linearly on the guide rail 19 . The connecting rod 21 drives the pull rod 17 and the carrying slide 15 to reciprocate on the roller 12 through the slider pin 18 on the guide block connector 20 (see FIG. 3 ). Wherein, guide rail 19 links to each other with support 49 by screw, and linear slider 47 and bearing 46 are installed on the support 49, and is connected by screw, and connecting rod 21 links to each other with support 46 through bearing and bearing pin 44 (see Fig. 6 ). Because the roller 12 sits on the casing through the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com