Method and device for measuring vector pressure taking advantage of capacitance change

A technology of capacitance change and vector, which is applied in the field of electrical measurement, can solve the problems of parallax caused by the pressure plate, the inability to use the touch screen, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

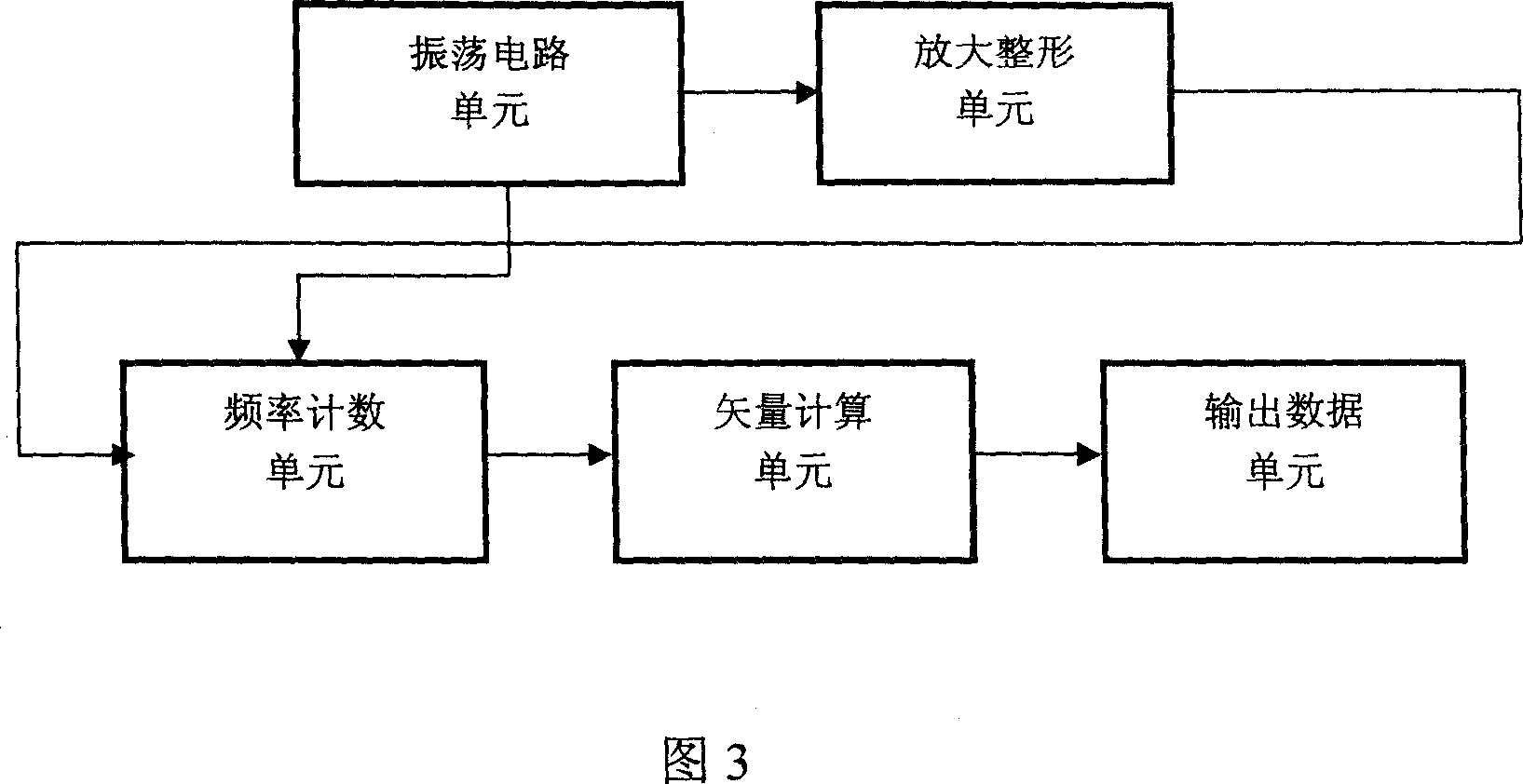

[0024] Embodiments of the present application will be described below in conjunction with the accompanying drawings.

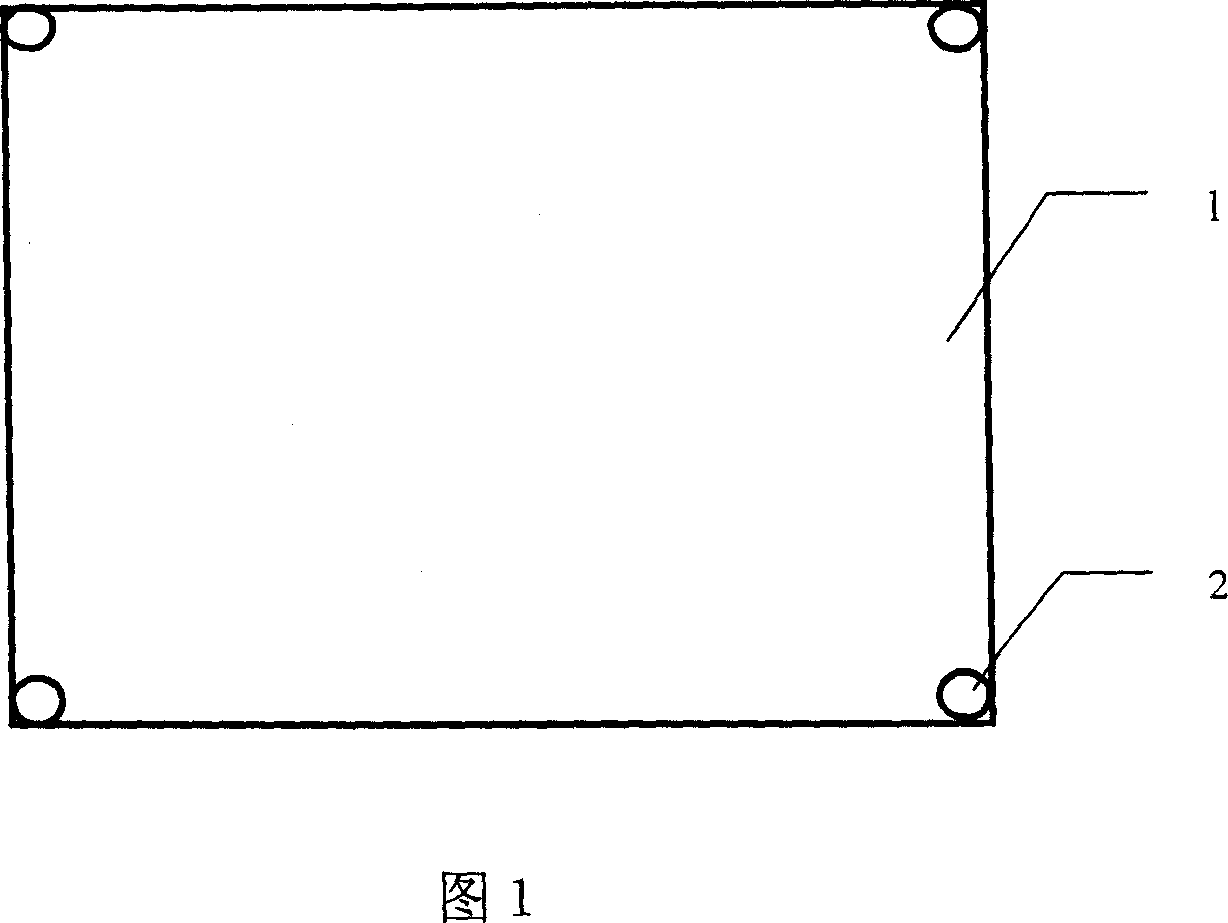

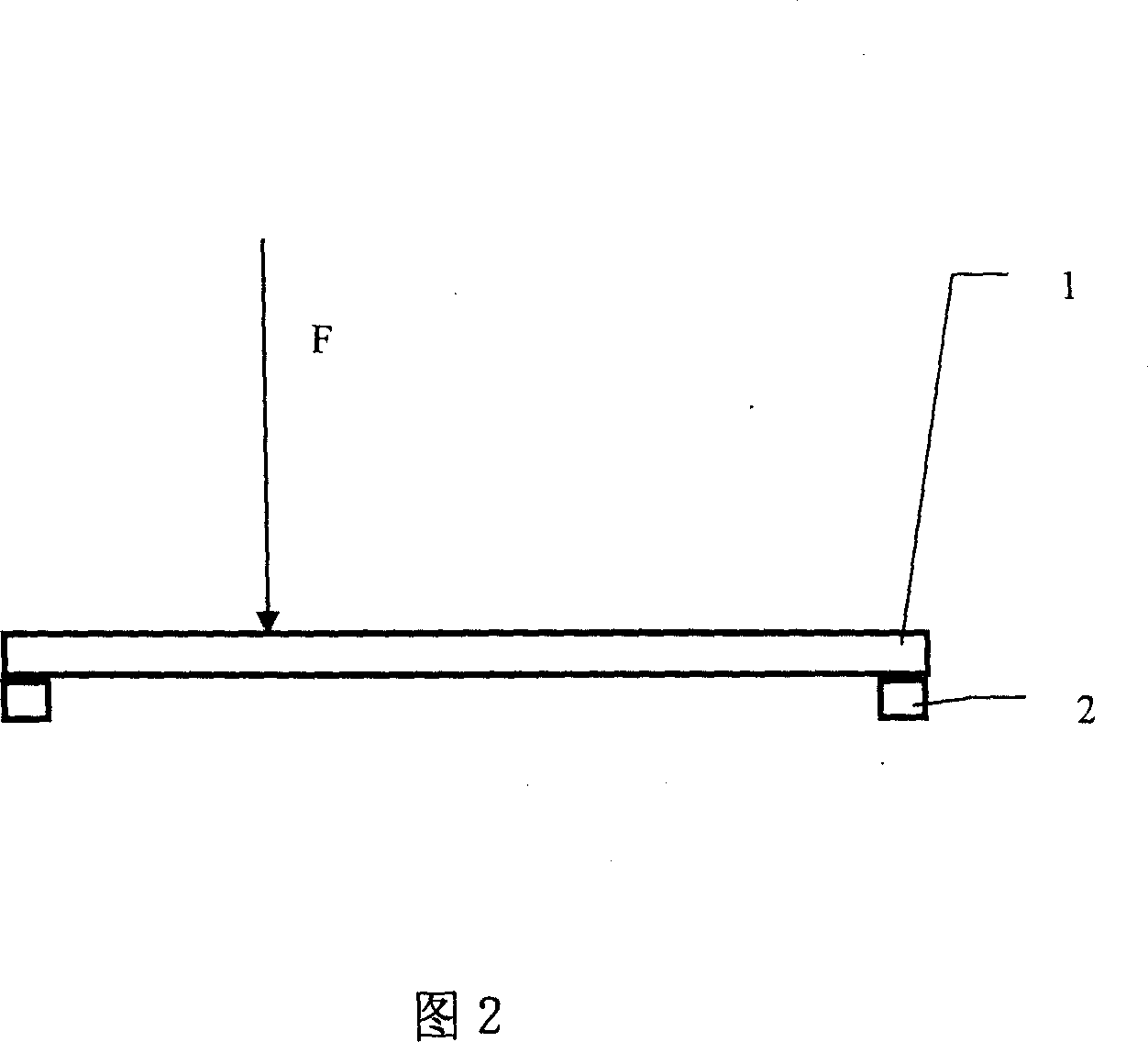

[0025] FIG. 1 is a bottom view of the device of the present invention, which includes a force plate 1 and a variable capacitance pressure sensor 2 . The stressed plate 1 is preferably a rigid plate, and the deformation of the rigid plate is small when subjected to external force, which is convenient for measurement and calculation. The variable capacitance pressure sensor 2 is arranged at a specific position of the force-bearing plate 1. In the embodiment of the present invention, it is arranged at the four vertices or tops of the force-bearing plate rectangular body and is relatively vertically distributed to measure the load on the force-bearing plate 1. Pressure information and output the corresponding signal.

[0026] The variable capacitance pressure sensor 2 is composed of a force bearing column 21 , an elastic electrode 22 , a gasket 23 , a dielectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com