Wooden screw nail structure

A screw and thread technology, applied in the field of wood screw structure, can solve problems such as construction failure, jamming, waste, etc., and achieve the effect of eliminating labor-consuming force, labor-saving cutting operation, and enhancing the function of chip collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

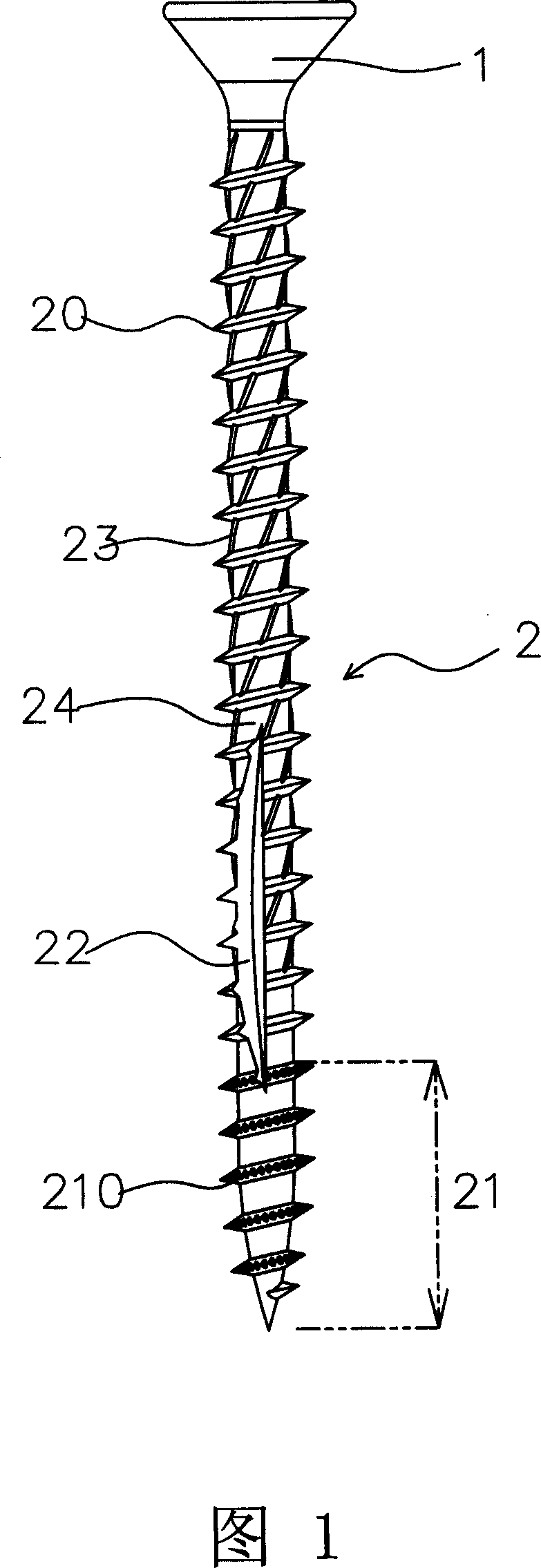

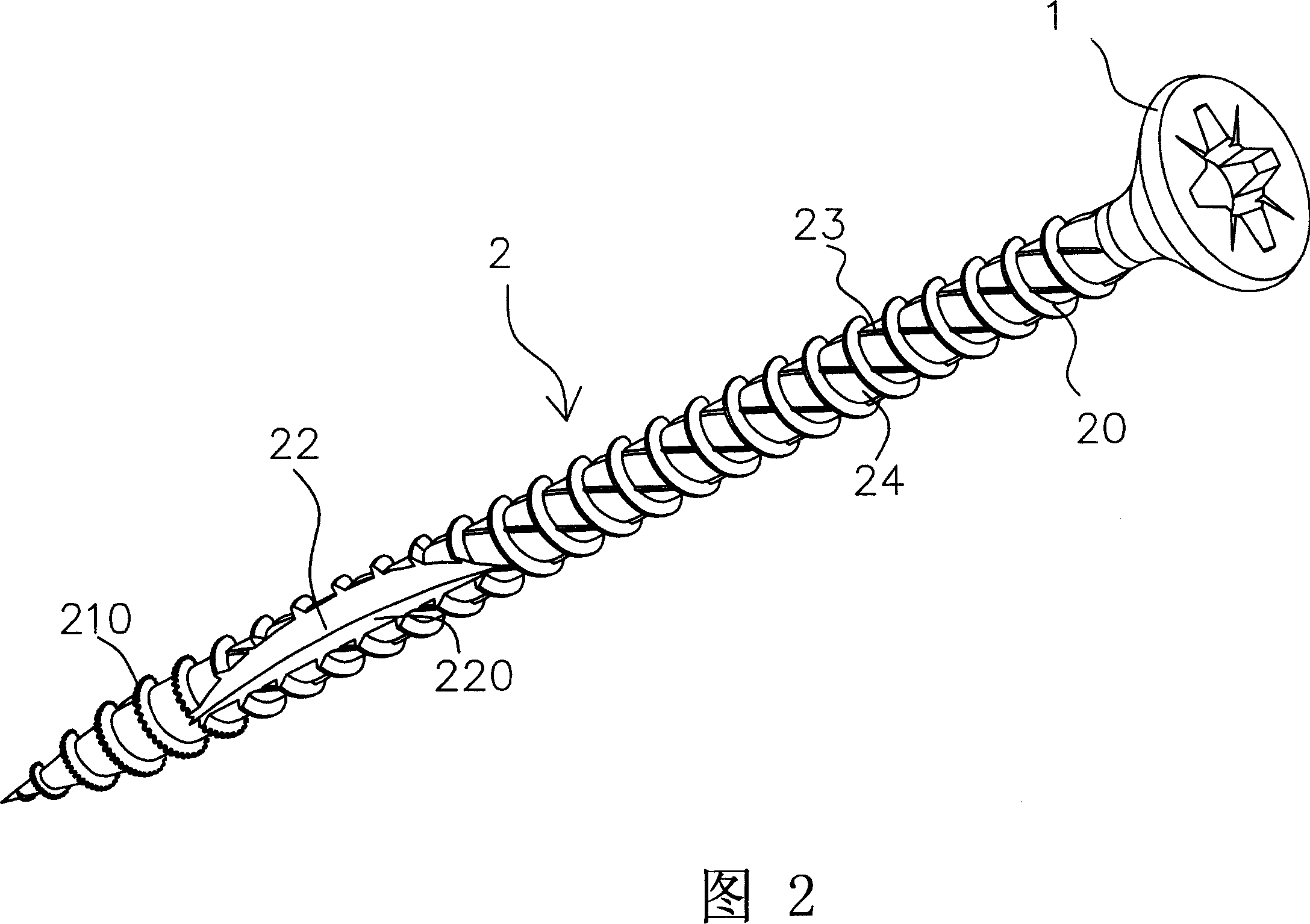

[0022] Referring to Fig. 1 and Fig. 2, the wood screw of the present invention is mainly composed of a head 1, a shank 2 and a plurality of threads 20 formed on the shank 2 and extending axially, wherein:

[0023] The rod part 2 is provided with a screw-in end 21 at the tip, and a plurality of cutting teeth 210 are provided on the plurality of threads 20 of the screw-in end 21, and a chip collecting groove 22 is longitudinally excavated behind the cutting teeth 210, and the chip collecting A cutting surface 220 is formed on both sides of the groove 22 , and the cutting teeth 210 extend backward to between the plurality of threads 20 of the head 1 , and are surrounded by protruding ribs 23 arranged obliquely.

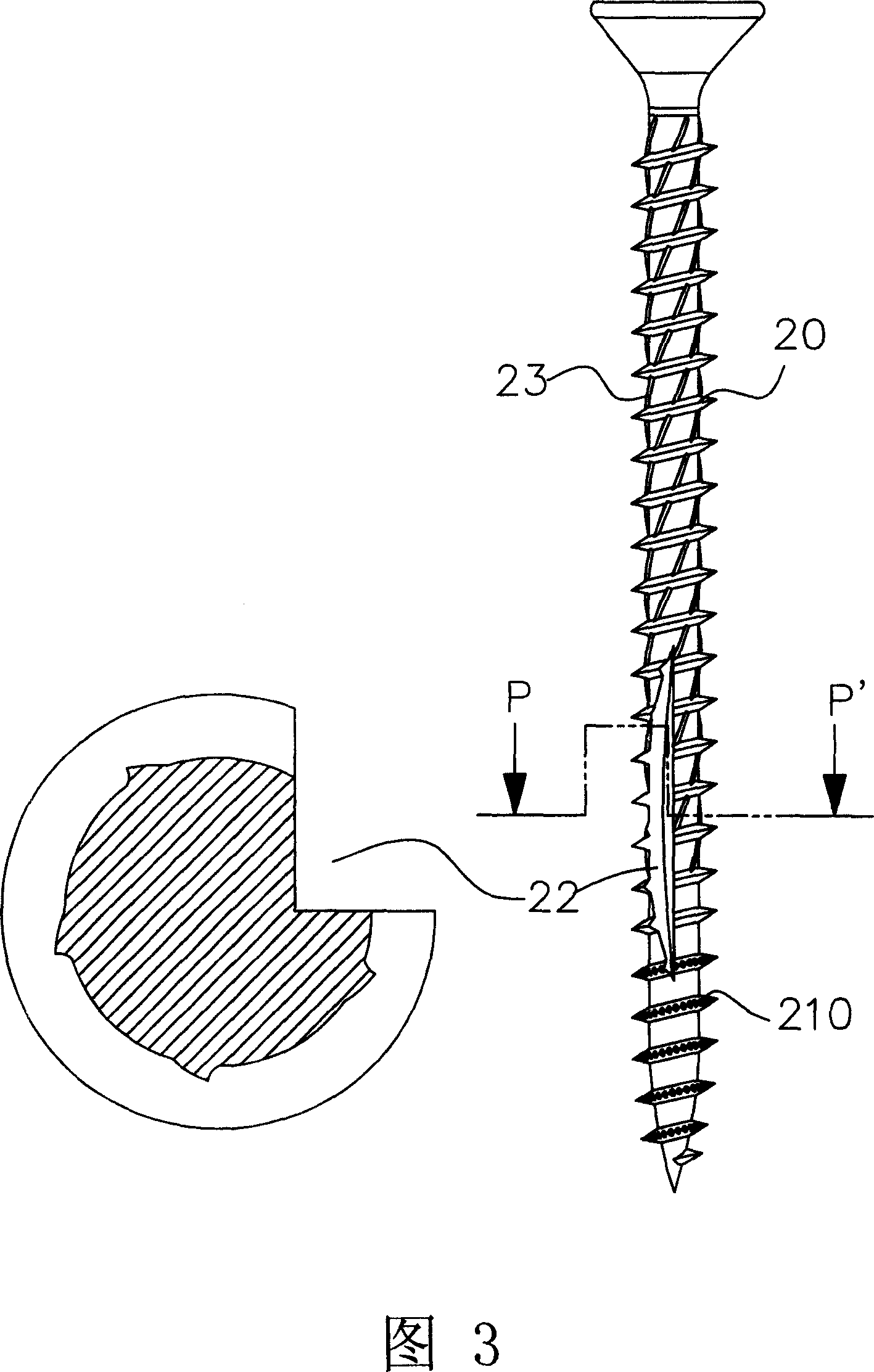

[0024] Please refer to Fig. 3 and shown in Fig. 4, when the wood screw of the present invention is used and implemented, the work system in the initial st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com