Flexibility process for grouping processing tobacco

A flexible method, tobacco technology, applied in tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of insufficient module refinement, limited modular processing, little difference in production routes, and methods, so as to achieve product personalization and differentiation, mutual waiting time reduction, and the effect of improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

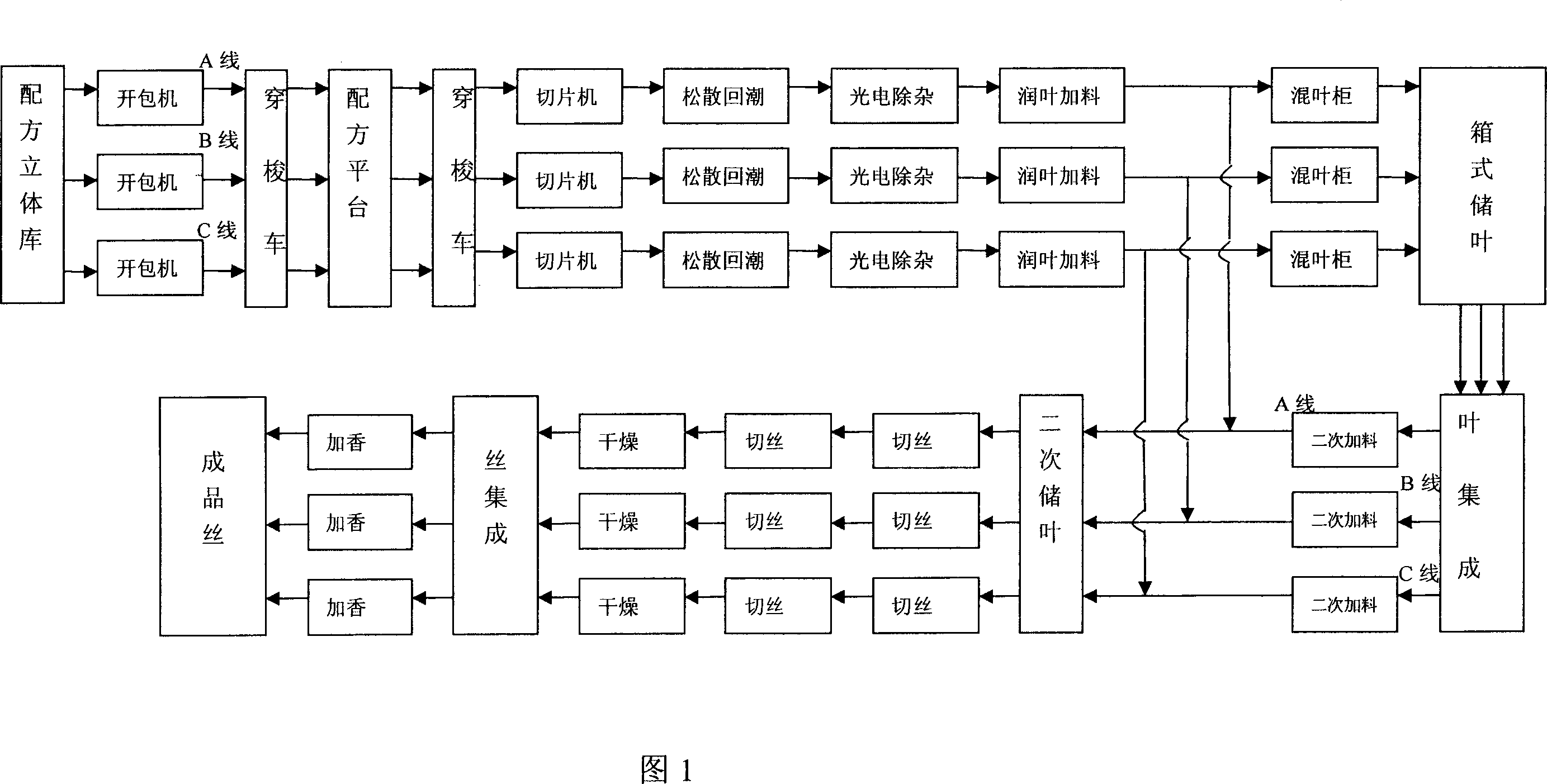

[0029]For example, if an existing brand is divided into 3 modules, which are produced by vertical grouping and processing, for the design of multi-line parallel arrangement, it is only necessary to select any silk production line as shown in Figure 1, line A, or line B, or For the C line, the modules of the brand can be produced sequentially.

Embodiment 2

[0031] For example, if an existing brand is divided into 3 modules, which are produced by vertical group processing, for the design of multi-line parallel layout, 3 silk production lines, namely the ABC line in Figure 1, are selected to process its modules at the same time. The leaf integration or wire integration in Figure 1 realizes module mixing, solves the single-line or double-line design method, and produces 3 modules. There must be a certain line that produces 2 or more modules, and the sequential production of modules results in the module produced first. The modules produced after waiting are mixed, which causes the production in the later stage to be in a waiting state, resulting in a waste of equipment capacity, and the problem that the storage time of each module is not easy to control. However, by adopting the multi-line parallel arrangement design of the present invention, this production mode can be easily realized.

Embodiment 3

[0033] If an existing brand is divided into multiple modules (3 or more), it is produced by vertical grouping processing. For multi-line parallel layout design, if the number of modules ≤ the number of production lines, as shown in Figure 1, A, B, and C3 production lines can adopt the module parallel production method; if the number of modules > the number of production lines, as shown in Figure 1 If there are 3 wire-making lines A, B, and C, and there are 4 or more modules, the parallel production mode of the first 3 modules can also be used, and the queuing principle can be used for more than one module produced later. After the production of the next module, if several production lines are completed at the same time, the subsequent module can choose the production line closest to its own processing parameters for production, saving equipment adjustment time. Through the queuing principle and the proximity principle, the production efficiency can be effectively improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com