Device with vibration-damped component used for cutting and grinding, clamp device and rotary tool

A technology of clamping device and rotating tool, which can be applied to the cutting tool of the sawing machine device, the part of the grinding machine tool, the device of fixing the grinding wheel, etc., which can solve the problems of health damage and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

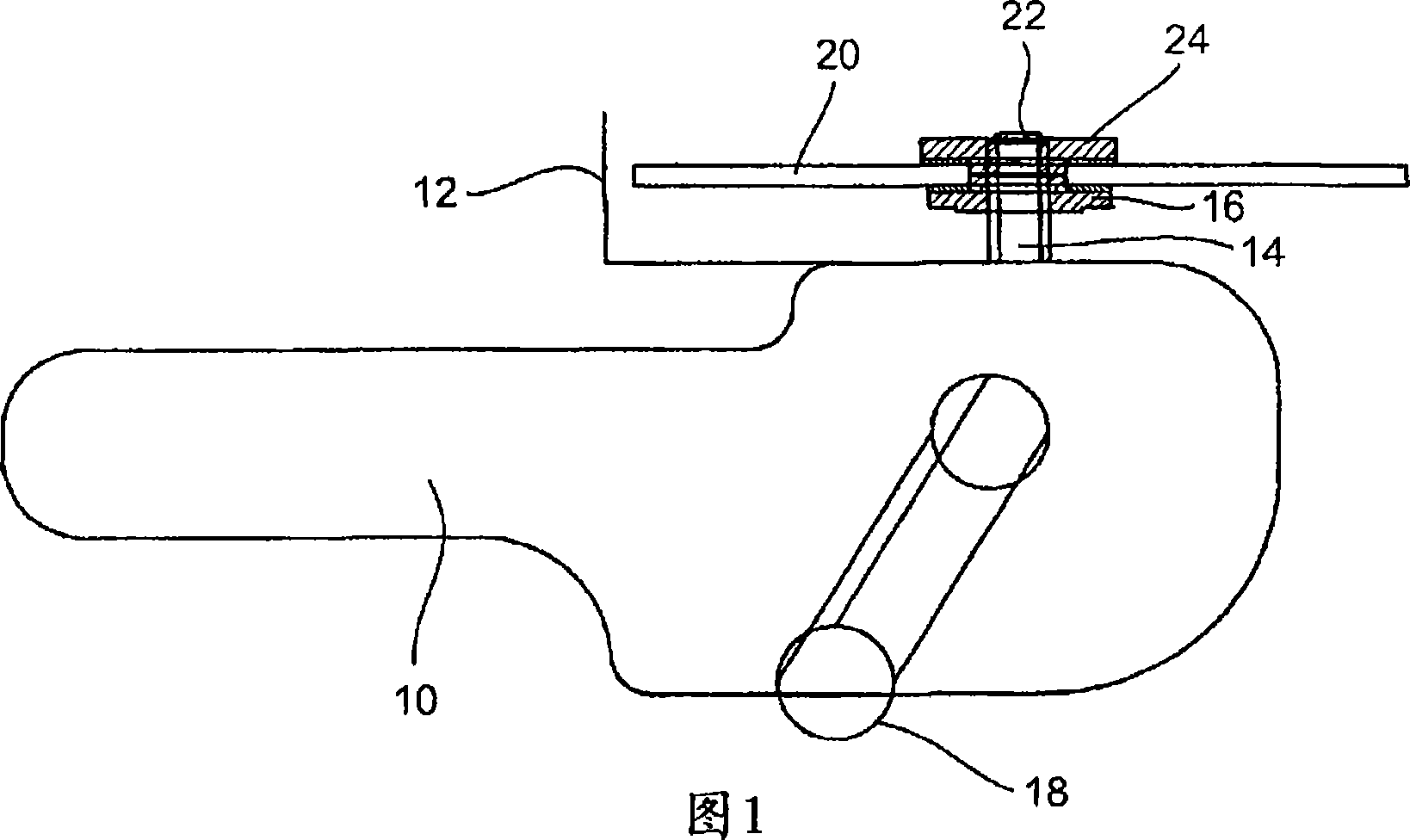

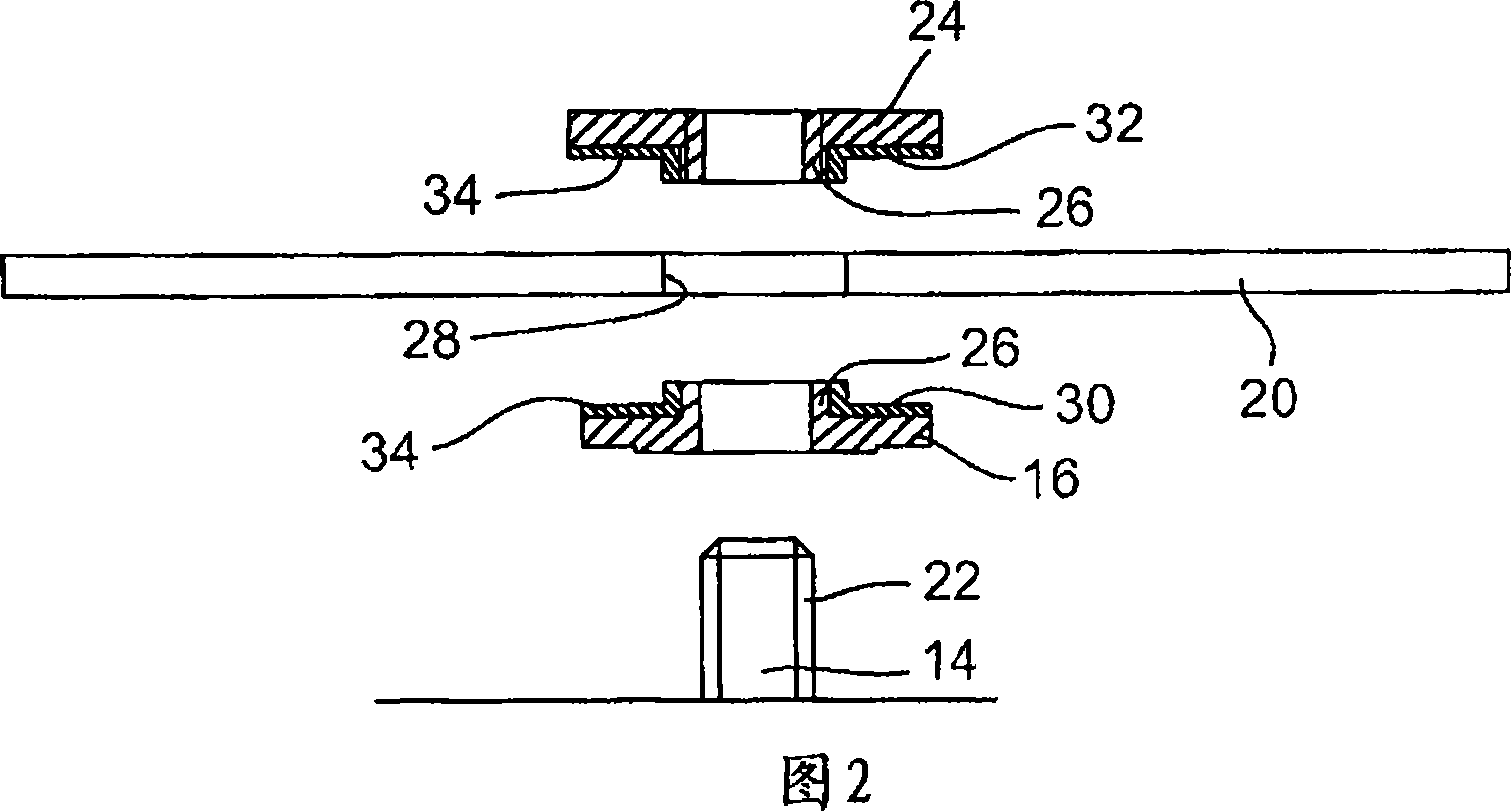

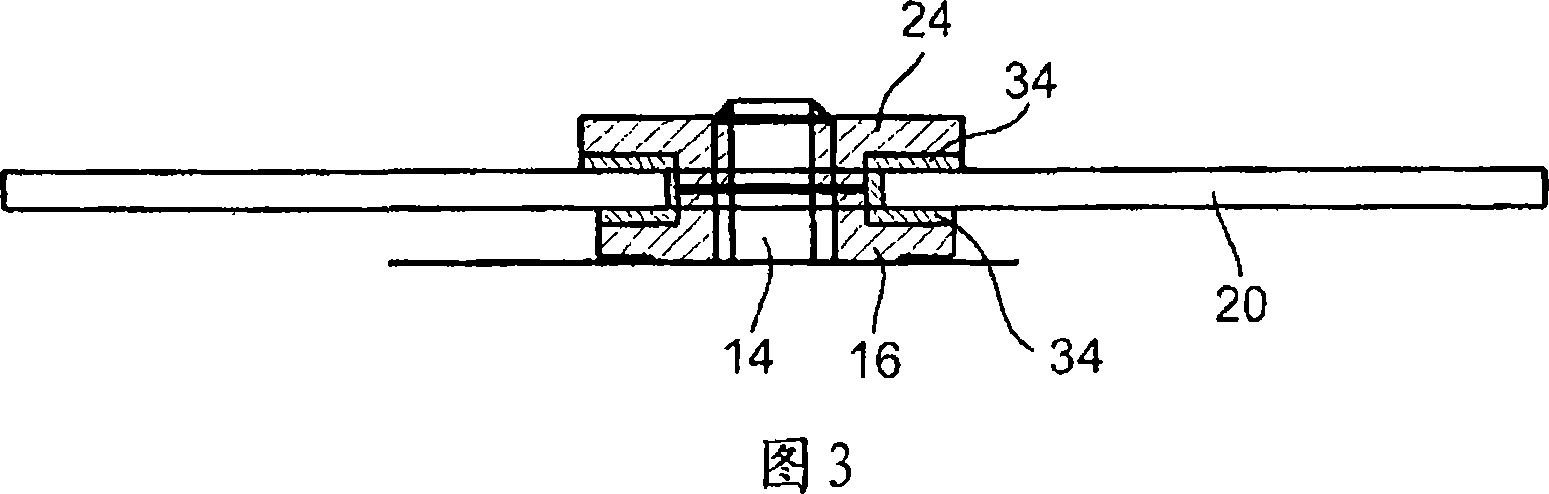

[0048] The universal angle grinder schematically shown in FIG. 1 includes a drive unit 10 and a handle 18 , the drive unit drives a transmission spindle 14 through a bevel gear transmission. The drive spindle 14 has a fastening flange 16 as a bearing for the rotary tool 20 . The outer end of the drive spindle 14 has an outer thread 22 , onto which a lock nut 24 is screwed, so that the tool 20 is clamped between the fastening flange 16 and the lock nut 24 . The fastening flange 16 and the union nut 24 have mutually opposing clamping faces 30 , 32 ( FIG. 2 ), between which the tool 20 is clamped. The fastening flange 16 can be formed integrally with the drive shaft 14 or can be a separate part, the fastening flange being engaged with the drive shaft 14 in a detachable but rotationally fixed manner. Around the edge of its central bore or around the shaft body of the drive spindle 14 , the fastening flange 16 has a flange 26 for cooperating with the tool 20 . The lock nut 24 als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com