Ultrathin triple-freedom inching work table

A workbench, degree of freedom technology, applied in workbenches, manufacturing tools, microlithography exposure equipment, etc., can solve the problems of high speed, large load, high dynamic characteristics, poor structural integrity, and high center of mass of lithography equipment. Achieve the effect of mature motion control technology, small inertia and low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

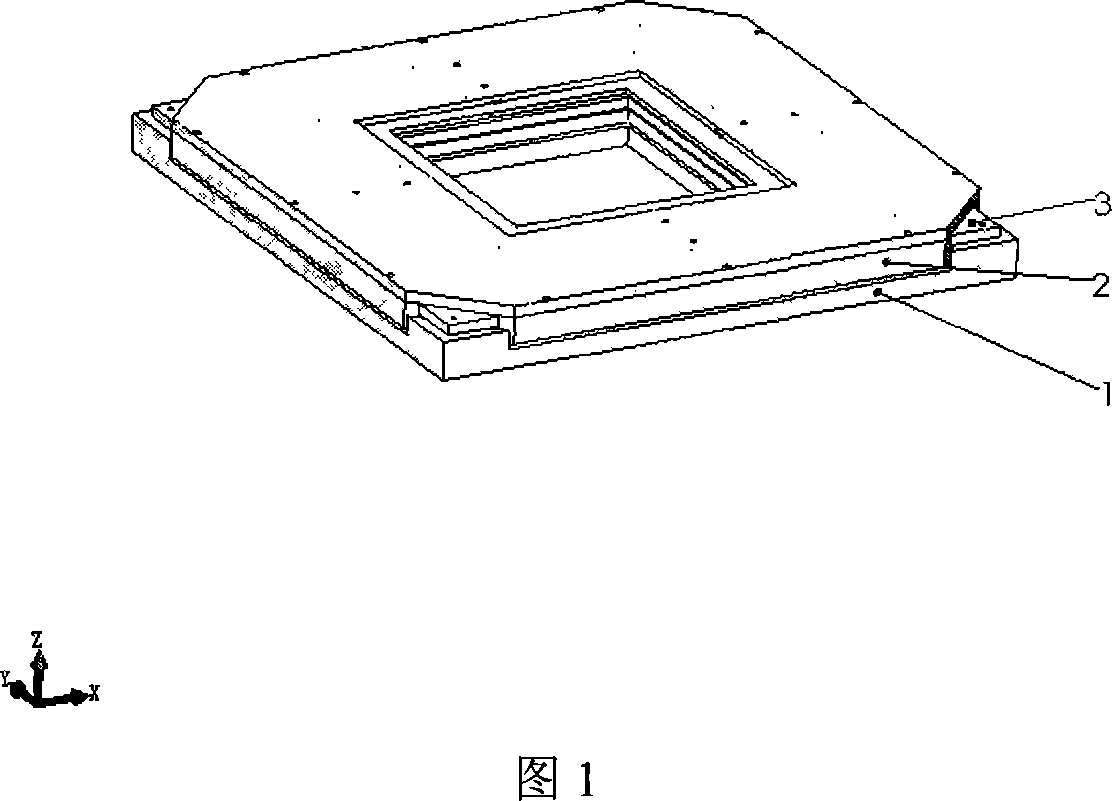

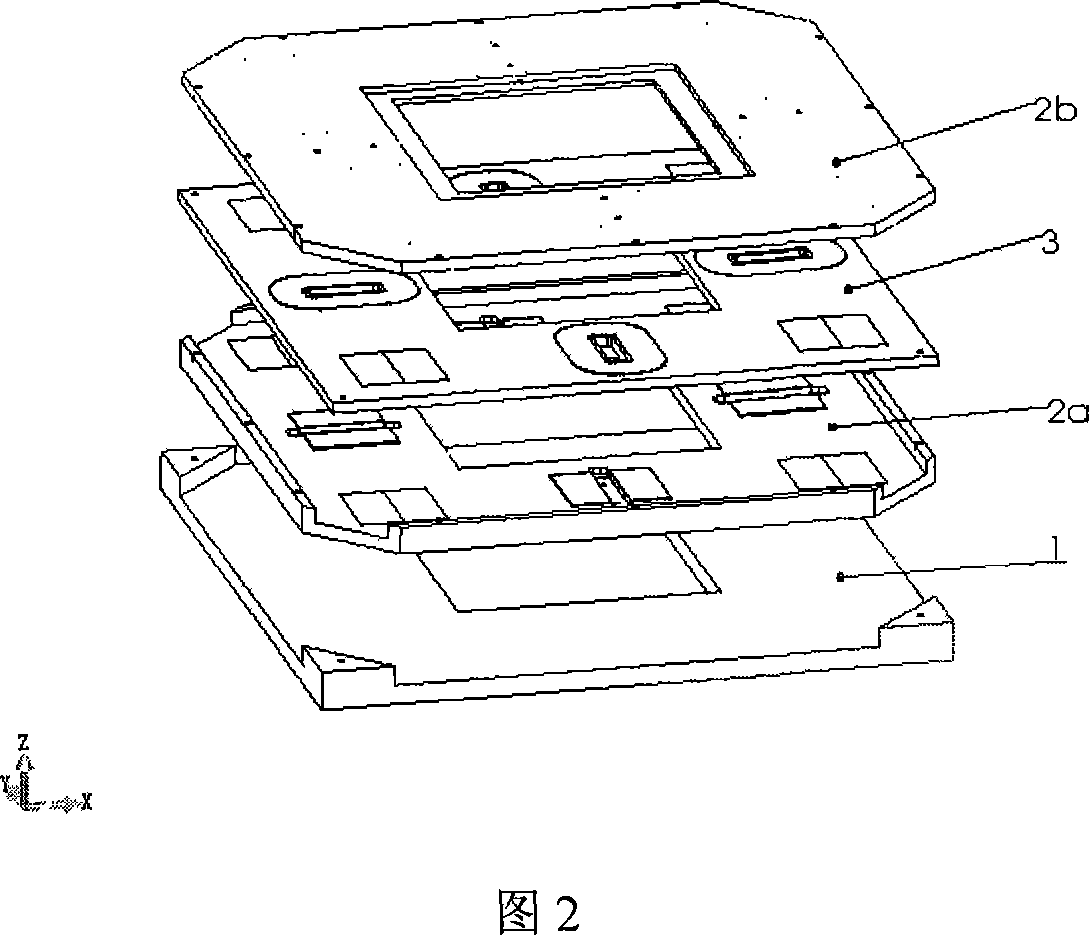

[0023] As shown in FIG. 1 , the micro-motion worktable of the present invention consists of three parts: a micro-motion table base 1 , a micro-motion table mover 2 , and a micro-motion table stator 3 . The mover 2 of the micro-motion table includes two parts, respectively a mover lower cover 2a and a mover upper slide cover 2b, both of which are fixedly connected. The four corners of the micro-motion table base 1 are processed with bosses, which play the role of supporting the micro-motion table stator 3 . The stator 3 of the micro-motion table is interposed between the lower cover 2a of the mover and the upper slide cover 2b of the mover, and is fixedly connected to the base 1 of the micro-motion table through a boss.

[0024] The micro-motion workbench has 3 sets of electromagnetic force drive units, each set of drive units contains at least one electromagnetic force drive unit, and each electromagnetic force drive unit is composed of an upper permanent magnet assembly, a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com