Near-bit logging data motor-passing wired transmission device

A technology of well logging data and cable transmission, which is applied in the field of oil drilling, can solve problems such as poor reliability, and achieve the effects of improved reliability, improved structural design, and less susceptible to interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

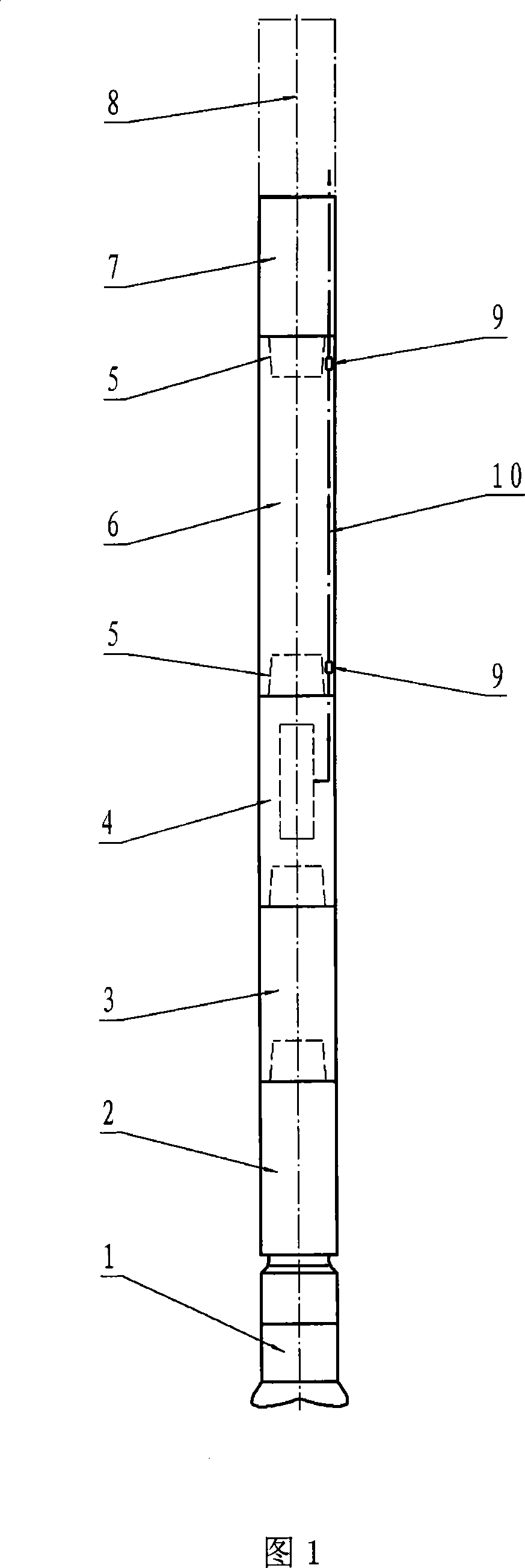

[0040] Embodiment 1: refer to accompanying drawing 1. The invention relates to a cable transmission device for near-drill logging data through a motor, which includes a measuring nipple 4 , a motor 6 and a bypass valve 7 . What motor 6 adopted is that diameter is the screw drilling tool of 172 millimeters. The upper end of the measuring nipple 4 is connected with a motor 6 through a thread 5 , and the upper end of the motor 6 is connected with a bypass valve 7 through a thread 5 . There are downhole measuring instruments in the measuring sub-section 4, and a MWD system 8 above the bypass valve 7. The data output interface of the downhole measuring instrument in the measurement sub-section 4 is connected with a data transmission wire 10, and the data transmission wire 10 passes through the casing of the measurement sub-section 4 and the thread 5 to connect the data transmission wire 10 in the housing of the motor 6; The data transmission wire 10 is connected to the data trans...

Embodiment 2

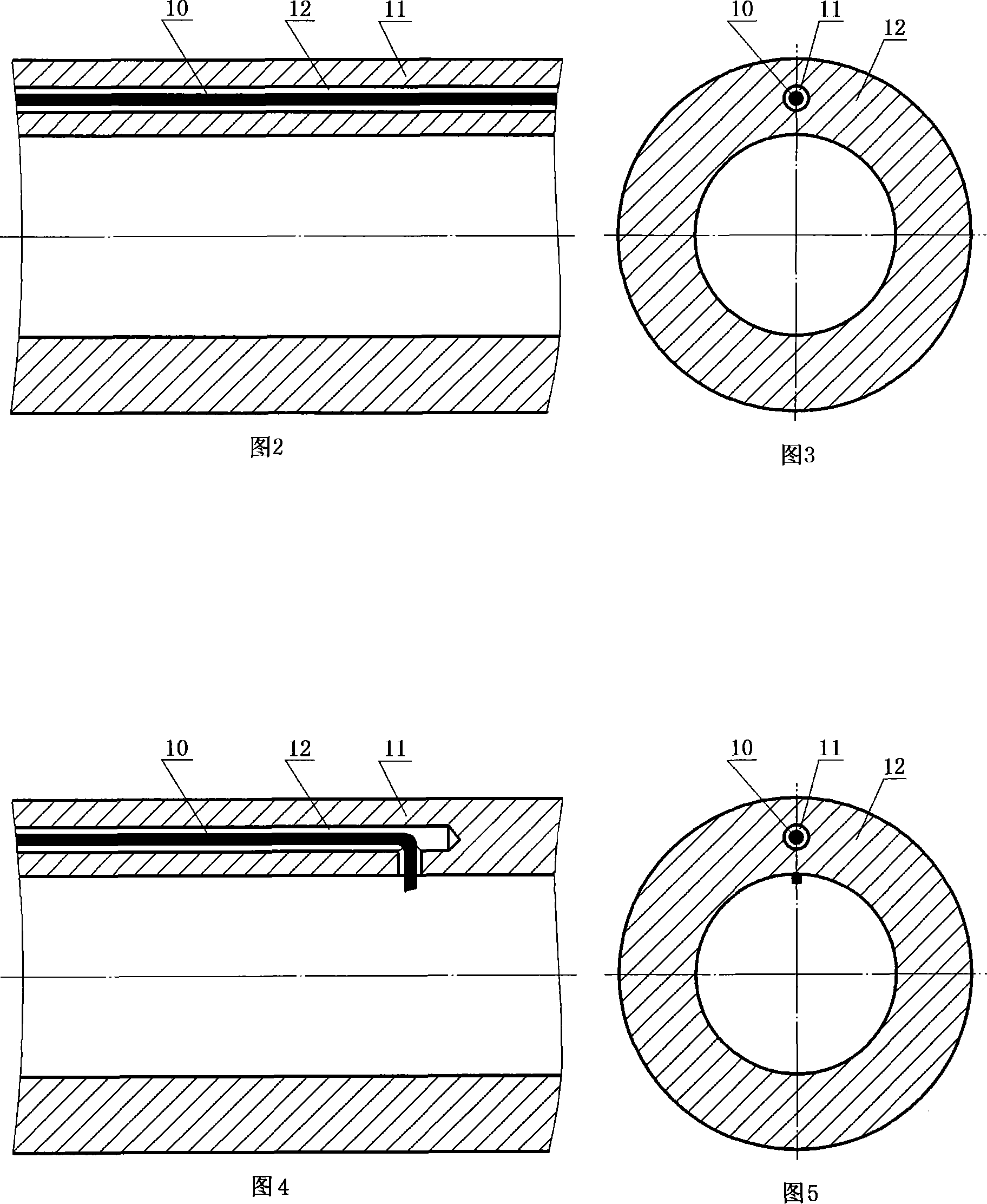

[0052] Measuring pup 4: Referring to Fig. 4 and Fig. 5, there is a radial hole 11 on the wall of the casing 12 of the measuring pup 4, and there is a data transmission wire 10 in the radial hole 11.

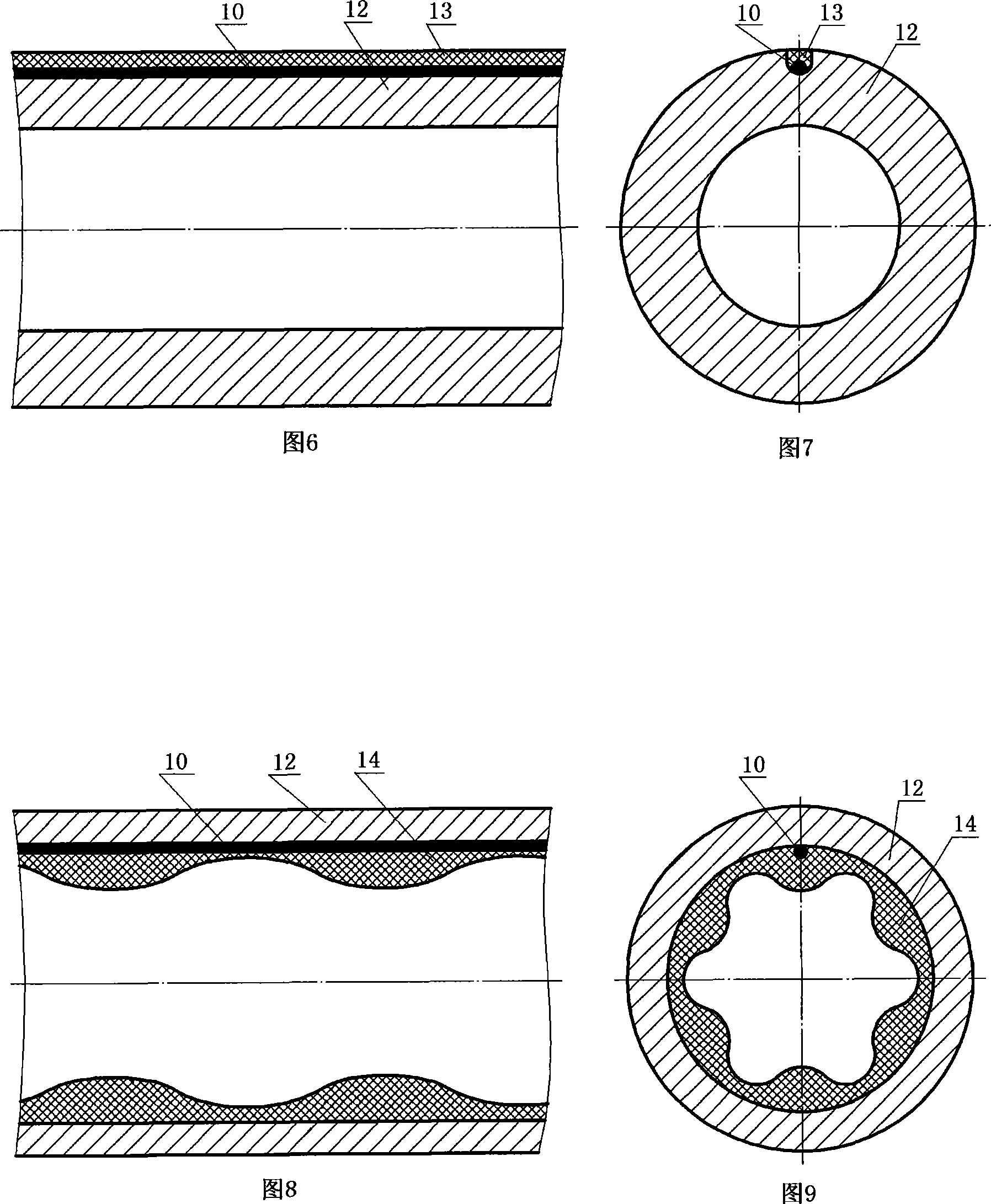

[0053] See Figure 6 and Figure 7. There is a groove on the outer surface of the housing 12, and there is a data transmission wire 10 in the groove, and a filler 13 is arranged in the groove to seal the groove, and the data transmission wire 10 is buried in the groove of the housing 12. The width of the groove is 5 mm, and the depth of the groove is 10 mm. The data transmission wires 10 in the radial holes 11 are connected with the data transmission wires 10 in the slots.

[0054] In addition, there is a radial hole 11 on the wall of the casing 12 at the other end of the measuring pup joint 4 , and there is a data transmission wire 10 inside the radial hole 11 . The purpose is to introduce the data transmission wire 10 in the groove into the housing 12 of the measuring sub 4 and...

Embodiment 3

[0060] Embodiment 3 is basically the same as Embodiment 1, except that the data transmission wire 10 is wound at the tooth root of the external thread 15 when passing through the thread. See Figure 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com