Single-hole composite anchoring pile

A technology for anchoring piles and bolts, used in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of stress concentration and inability to distribute loads evenly in ordinary anchoring piles, and achieve simple and economical construction machinery, high bearing capacity, and construction. The effect of low site conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

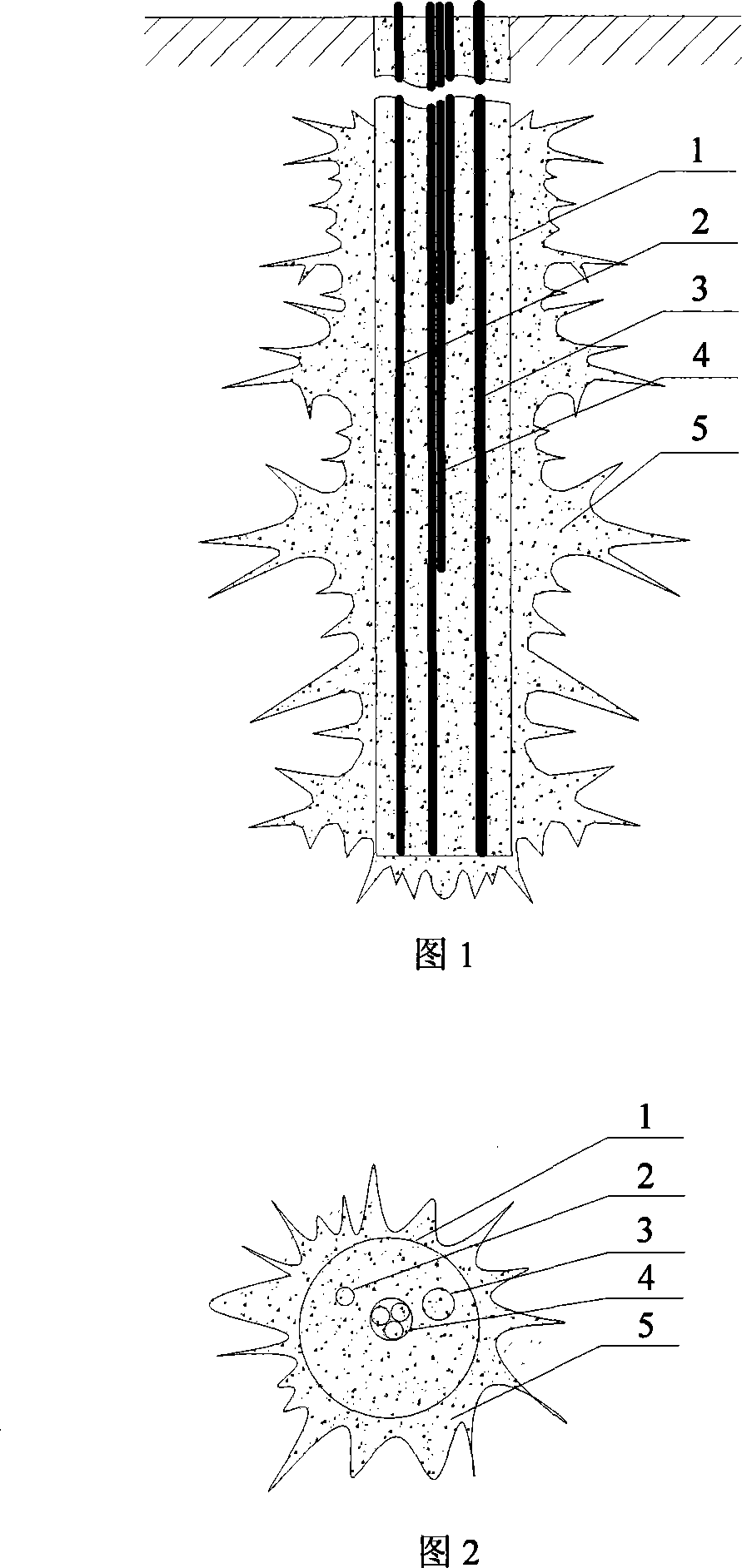

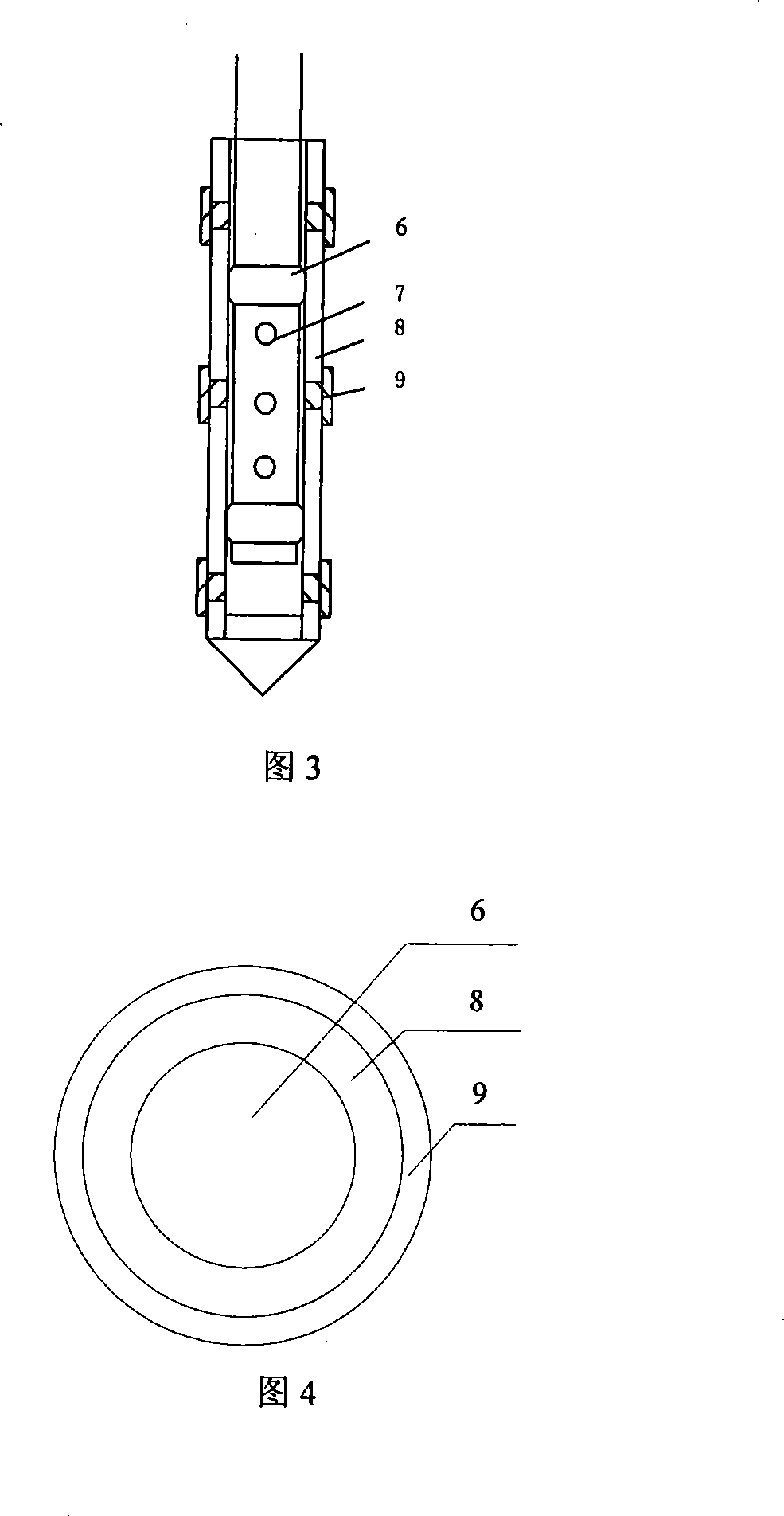

[0015] In the single-hole composite anchor pile shown in the figure, 1 is the drill hole, 2 is the grouting pipe, 3 is the sleeve valve pipe, 4 is the anchor rod body, 5 is the grouting body, 6 is the sleeve valve pipe grout stopper, 7 For the sleeve valve pipe grouting hole, the 8th is the sleeve valve pipe flower pipe, and the 9th is a rubber sleeve. In the implementation process, the hole forming machine is first used to form a drill hole 1 with a diameter of 130mm and a depth of 12.5m, and insert the grouting pipe 2, the sleeve valve pipe 3 and the anchor body 4, the grouting pipe 2 and the sleeve valve pipe 3 The length is the same as the depth of the borehole 1, and each anchor body is installed with two secondary hot-rolled rebars with a diameter of 32mm, the lengths are 12m and 6m, and the lengths of the free sections are 7m and 0m respectively. First, use the grouting pipe 2 to carry out a grouting. The grouting material is ordinary silicon 32.5 grade cement, and the ...

Embodiment 2

[0017] In the implementation process, the hole forming machine is firstly used to form a drill hole 1 with a diameter of 150mm and a depth of 15m, inserting the grouting pipe 2, the sleeve valve pipe 3 and the anchor body 4, and the length of the grouting pipe 2 and the sleeve valve pipe 3 At the same depth as drilling hole 1, each bolt body is equipped with three secondary hot-rolled rebars with a diameter of 22mm, the lengths are 15m, 9m and 5m, and the lengths of the free sections are 8m, 5m and 0m respectively. First, use the grouting pipe 2 to carry out a grouting. The grouting material is ordinary silicon 32.5 grade cement, and the water-cement ratio of the slurry is 0.5:1. Pipe 3 implements secondary grouting, and the secondary high-pressure grouting is related to the undisturbed soil conditions, pile hole depth, position, and grouting sequence. According to the site conditions of a member store in this embodiment, the secondary medium-high pressure grouting pressure is ...

Embodiment 3

[0019] In the implementation process, the hole forming machine is firstly used to form a drill hole 1 with a diameter of 150mm and a depth of 16m. Insert the grouting pipe 2, the sleeve valve pipe 3 and the anchor rod body 4. The length of the grouting pipe 2 and the sleeve valve pipe 3 is At the same depth as drilling hole 1, each bolt body is equipped with three secondary hot-rolled rebars with a diameter of 25mm, the lengths are 11m, 8m and 5m, and the lengths of the free sections are 6m, 4m and 0m respectively. First, use the grouting pipe 2 to carry out a grouting. The grouting material is ordinary silicon 32.5 grade cement, and the water-cement ratio of the slurry is 0.5:1. Pipe 3 implements secondary grouting. The secondary high-pressure grouting is related to the undisturbed soil conditions, pile hole depth, position, and grouting sequence. According to the site conditions of a member store in this embodiment, the secondary high-pressure grouting pressure is designed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com