Crane electromagnet for lifting high-temperature vertical steel roll

A lifting electromagnet and electromagnet technology, which is applied in the field of lifting electromagnet, can solve the problems of high energy consumption and self-heavy weight of the electromagnet, and achieve the effect of improving the lifting capacity, reducing the self-weight, and facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

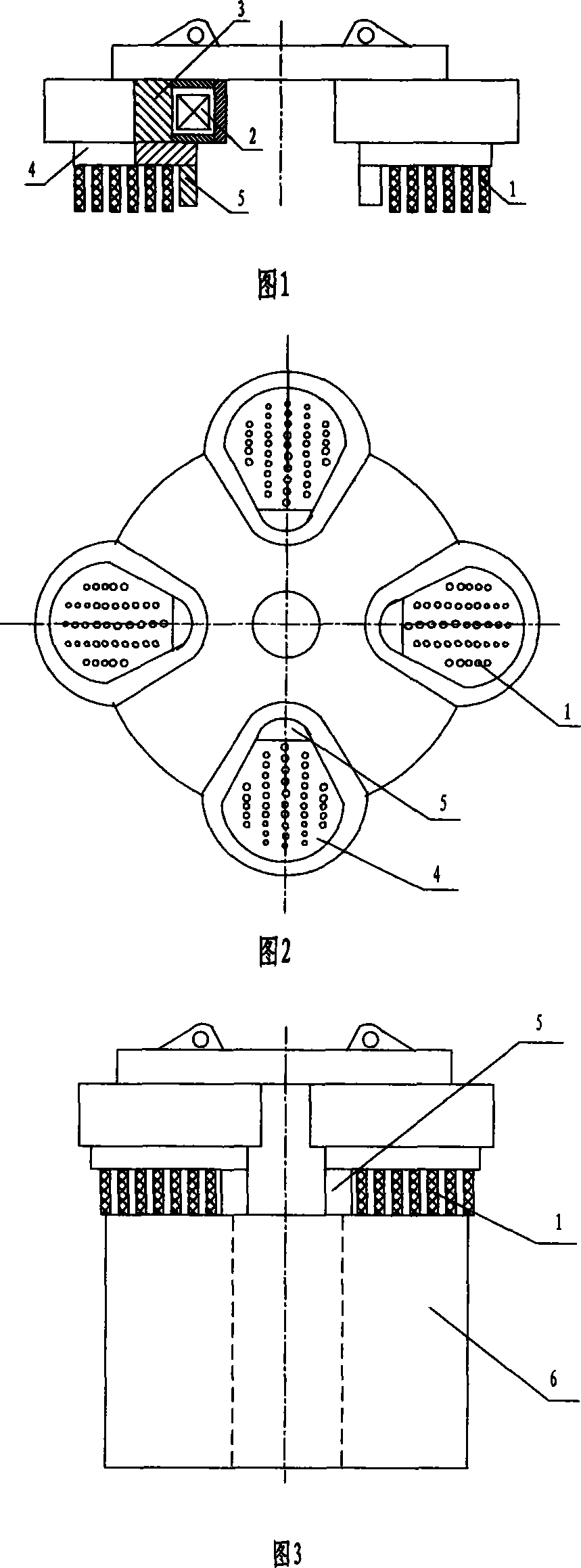

[0013] It can be seen from Fig. 1 and Fig. 3 that the lifting electromagnet for hoisting high-temperature vertical steel coils in the present invention is an electromagnet with two magnetic poles in a "U"-shaped structure, with two coils 2 and magnetic poles 4, and the coil 2 is installed in the housing. , and weld the end plate of the shell, the outer periphery of the shell is an antimagnetic plate, the magnetic pole 4 is fixed with the iron core 3 by bolts, and the inner bottom surface of the magnetic pole 4 is welded with a support plate 5 perpendicular to it. The height of the support plate 5 is 200mm. The rest of the bottom surface of the magnetic pole 4 is evenly fixed with rope clips on the upper ends of multiple flexible magnetic poles 1, and the lower ends are free to hang down. The length of the flexible magnetic poles 1 is 20mm greater than the height of the support plate 5; The sum of the cross-sectional area of the upper support plate 5 is equal to the cross-sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com