Stepless speed changer

A continuously variable transmission, conical technology, applied in the direction of friction transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of inability to realize movement and power cut-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

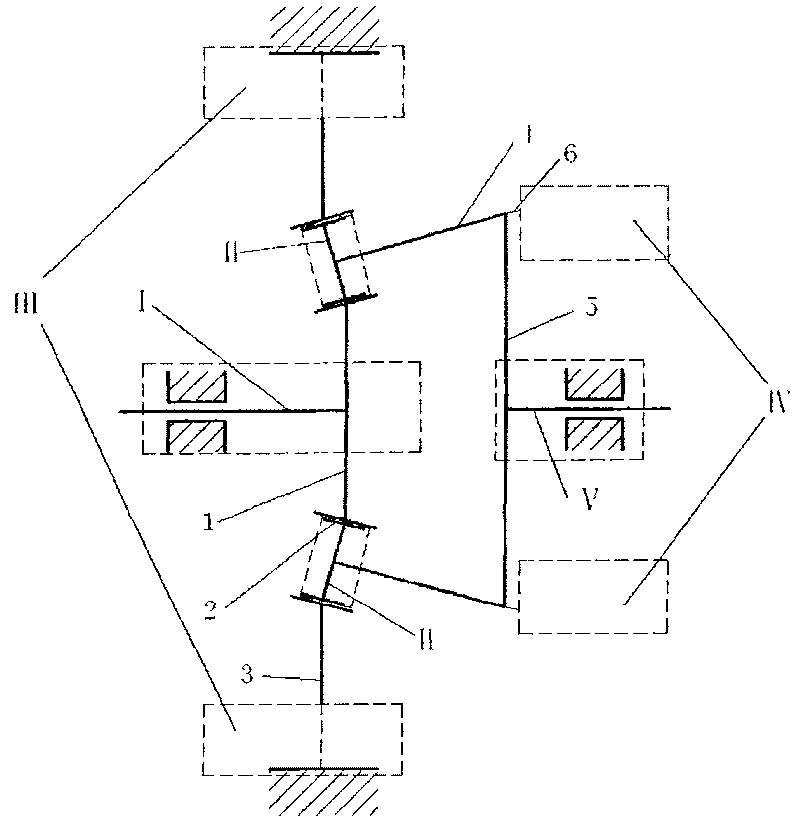

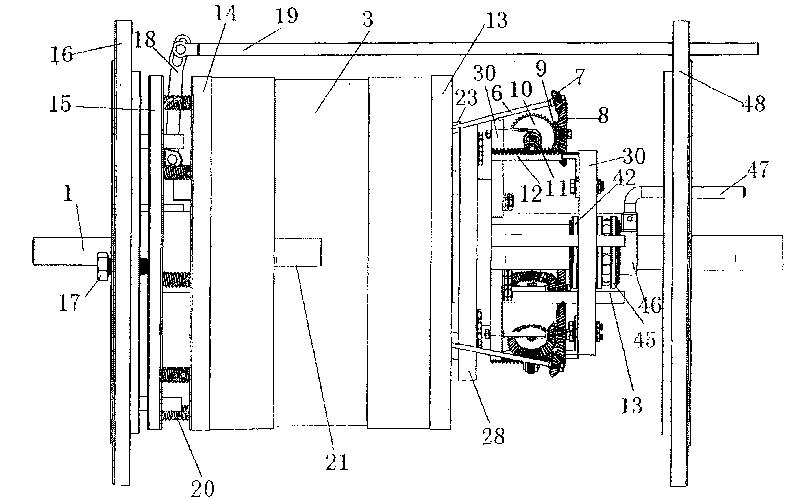

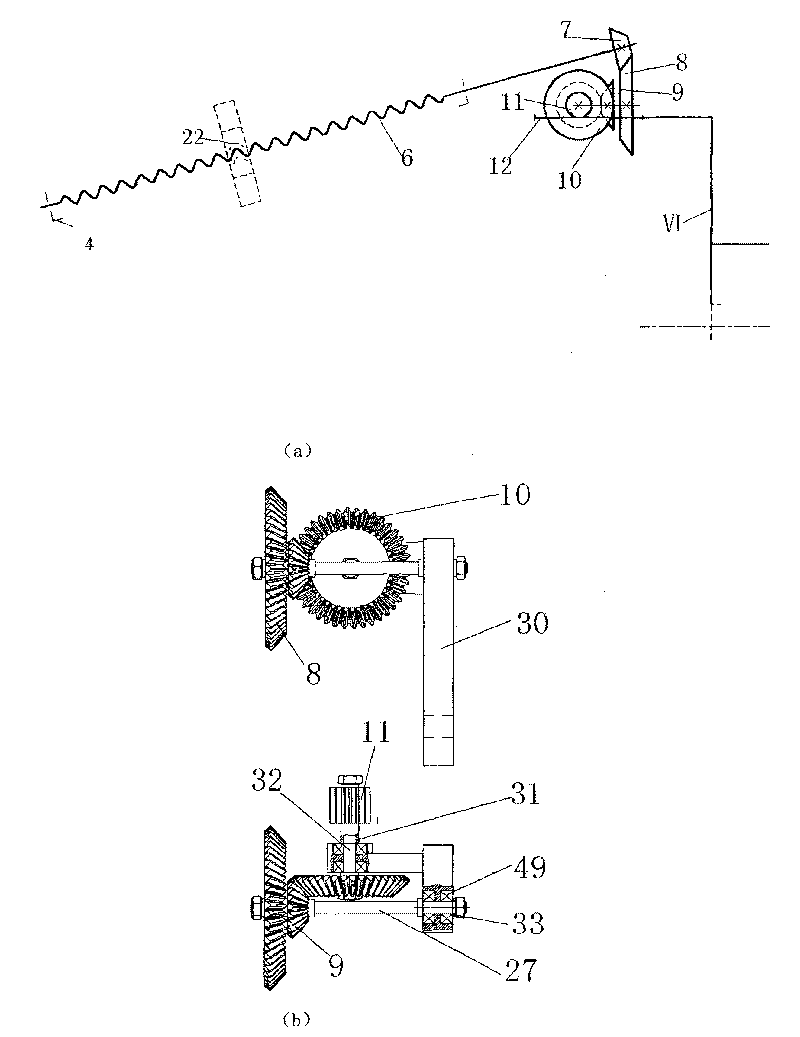

[0018] exist figure 1 Among them, the detachable and fixed inner conical friction wheel 3 is controlled by the pressure control mechanism III to make it compact or separate, so as to indirectly load or remove the pressure on the conical sun gear 1, so that the conical sun gear 1 Friction with the friction wheel 2 of the planetary gear system makes the friction wheel 2 of the planetary gear system rotate. At the same time, it also directly loads or unloads the pressure of the separable fixed inner conical friction wheel 3 on the friction wheel 2 of the planetary gear system, and the planetary gear system friction wheel 2 The friction wheel 2 of the gear train and the detachable fixed inner conical friction wheel 3 contact to generate friction, which causes the planetary gear train mechanism II to revolve, and the revolution of the planetary gear train II is transmitted to the output shaft disc 5 through the planet carrier 4, and the output shaft disc 5 Export movement and power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com