Induction type connecting shaft

A connecting shaft and inductive technology, applied in the field of inductive connecting shafts, can solve the problems of inconvenience, inability to achieve continuous speed change, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

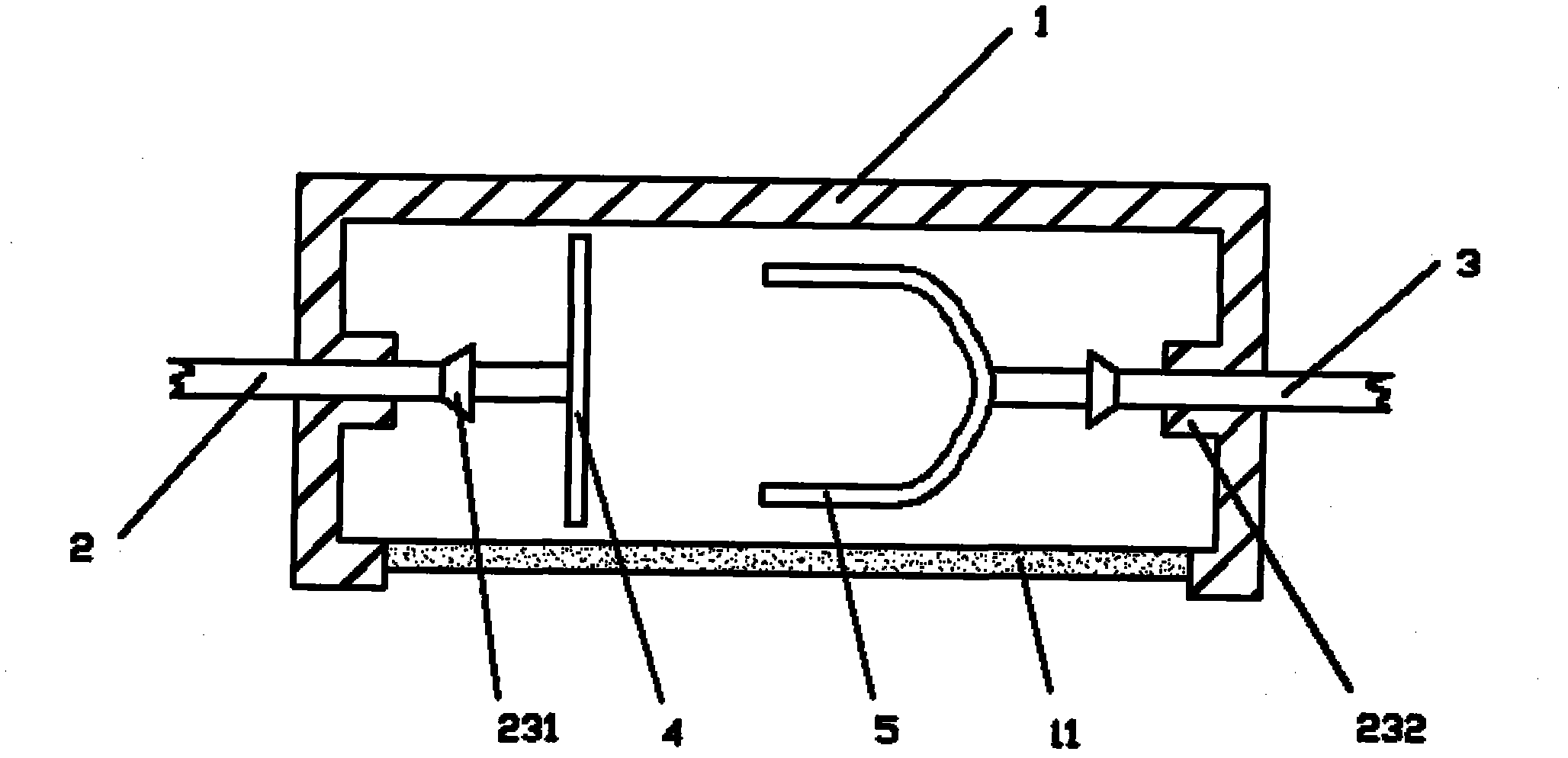

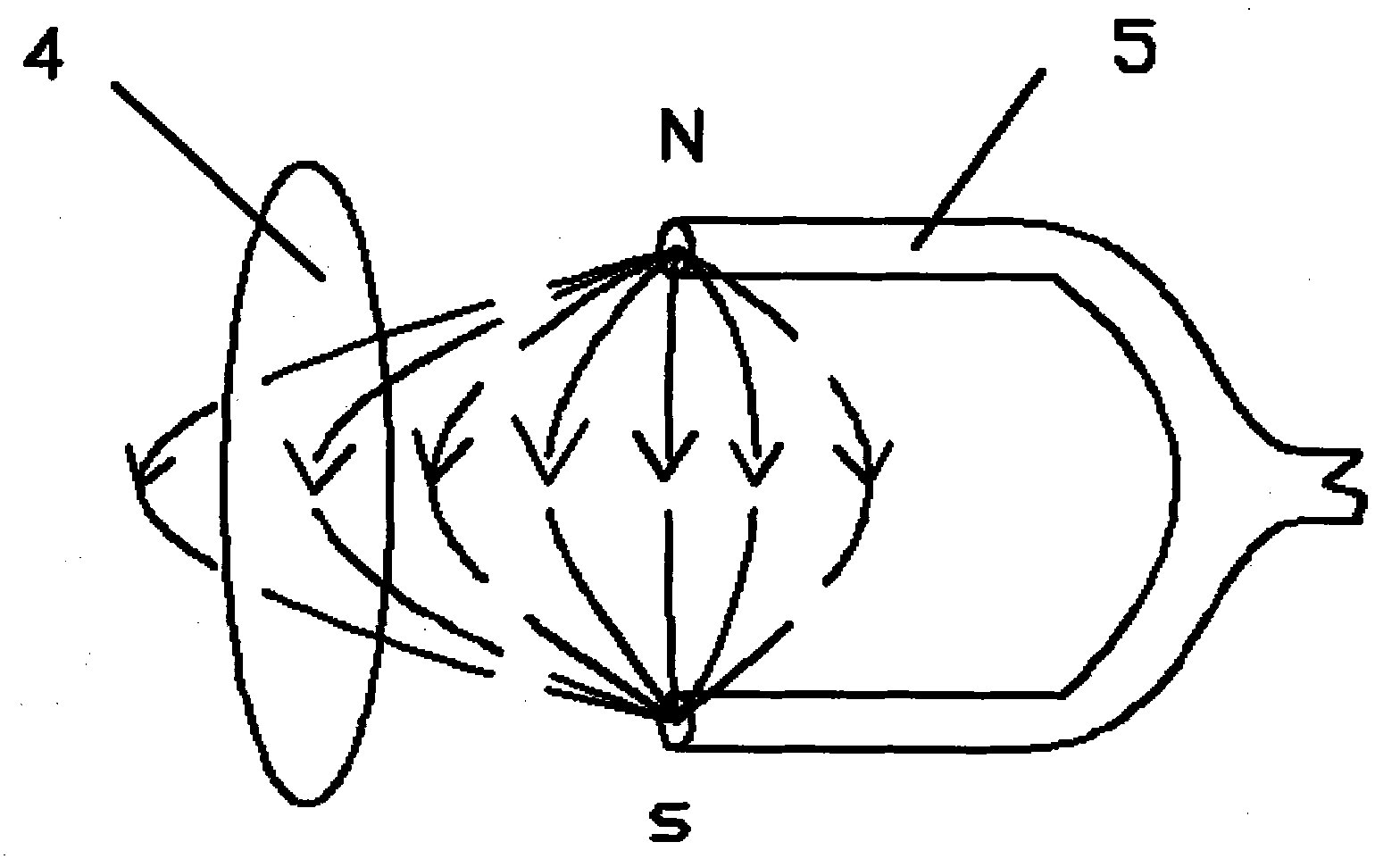

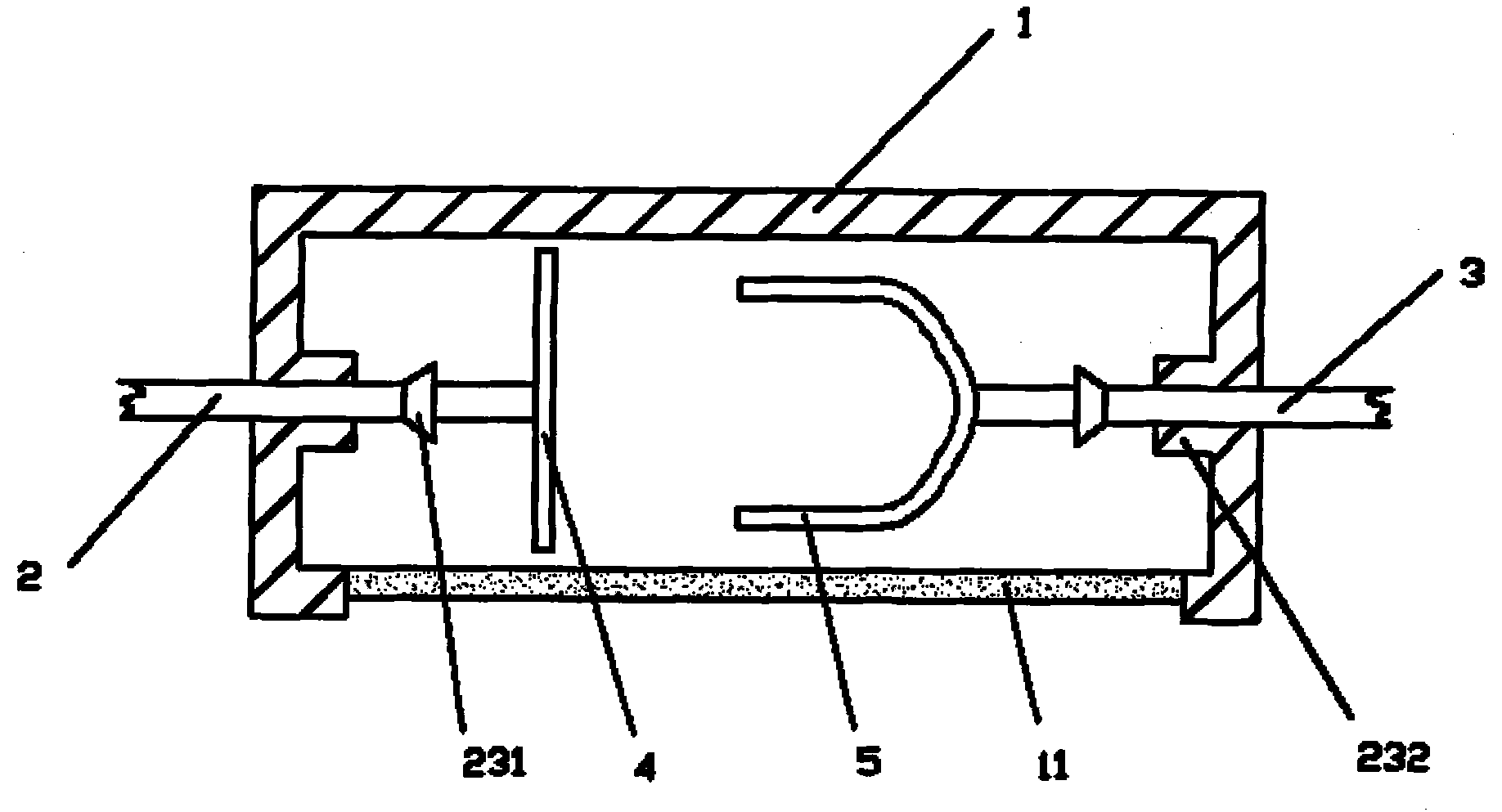

[0012] exist figure 1 , figure 2 In the shown embodiment, the inductive connecting shaft includes a connecting cylinder 1, an input leading shaft 3, and an output leading shaft 2, and the input leading shaft 3 and the output leading shaft 2 protrude through the bearings 232 at both ends of the connecting cylinder 1. In the connecting cylinder 1, a horseshoe-shaped permanent magnet 5 is fixed at the end of the input guide shaft 3, and a circular aluminum plate 4 is fixed at the end of the output guide shaft 2, and the horseshoe-shaped permanent magnet 5 and the circle Shaped aluminum plates 4 are arranged oppositely in the connecting cylinder 1, and the input guide shaft 3 and the output guide shaft 2 are respectively connected to the input shaft and the output shaft outside the connecting cylinder 1.

[0013] For the above-mentioned inductive connection shaft, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com