Automatic spraying fire extinguisher with detecting and alarming functions

A fire extinguishing device and automatic opening and closing technology, which is applied in fire rescue and other fields, can solve the problems of liquid bubble explosion time lag, difficulty in reaching the explosion temperature of glass bubbles, and non-rotating nozzles, etc., and achieve the effect of high fire extinguishing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

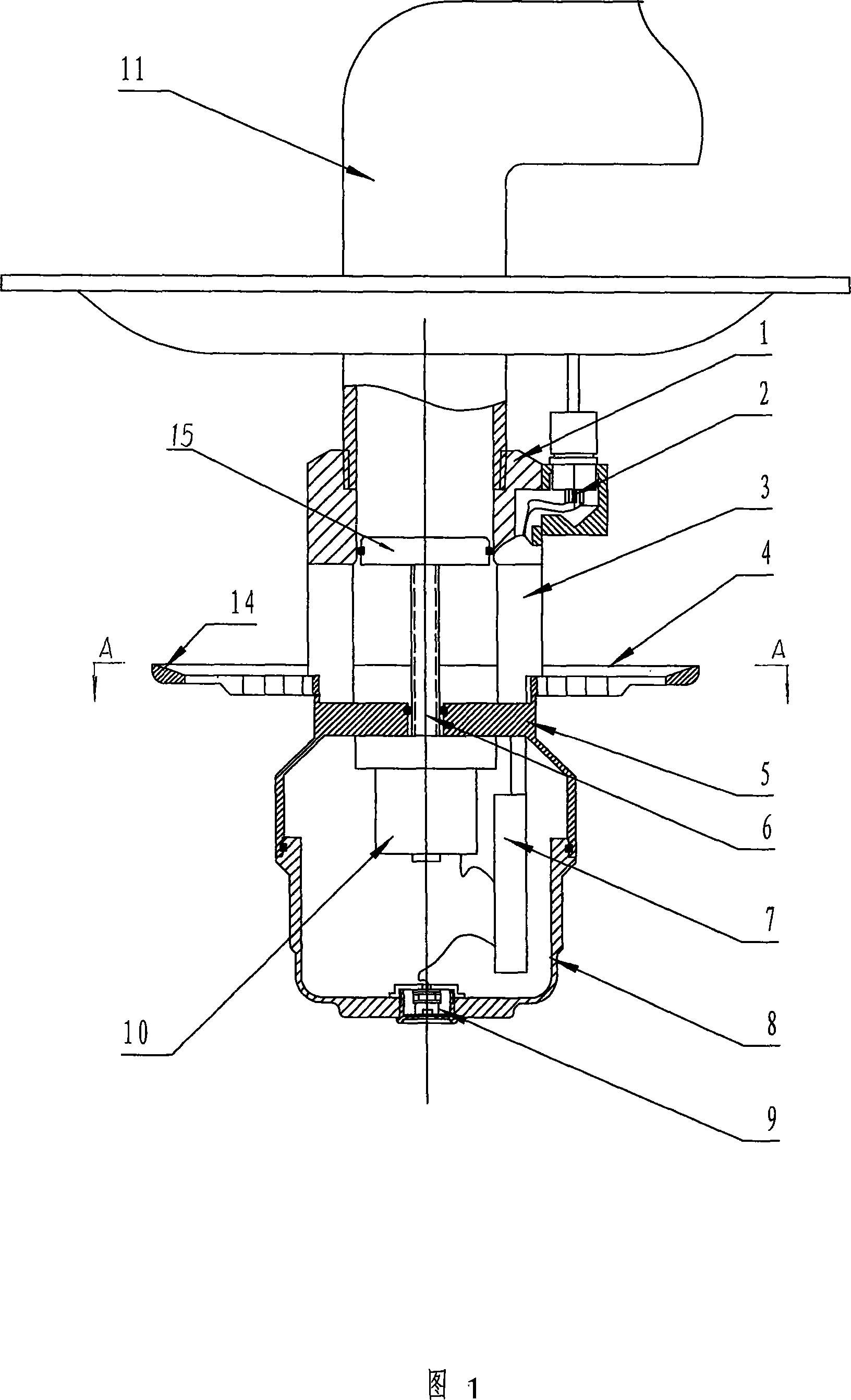

[0024] Embodiment 1: Please refer to Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, and Figure 8. The main shaft 1 of the present invention is connected to the water supply pipe 11 of the system, and the lower end is connected to the bracket 3, the device body 5, and the splash plate 4 A rigid structure is formed, and an opening and closing mechanism 6 is installed in the middle of the device body 5. The opening and closing mechanism 6 compresses the sealing ring at the lower end of the main shaft 1 upwards, and the motor 10 controls the opening and closing of the opening and closing mechanism 6.

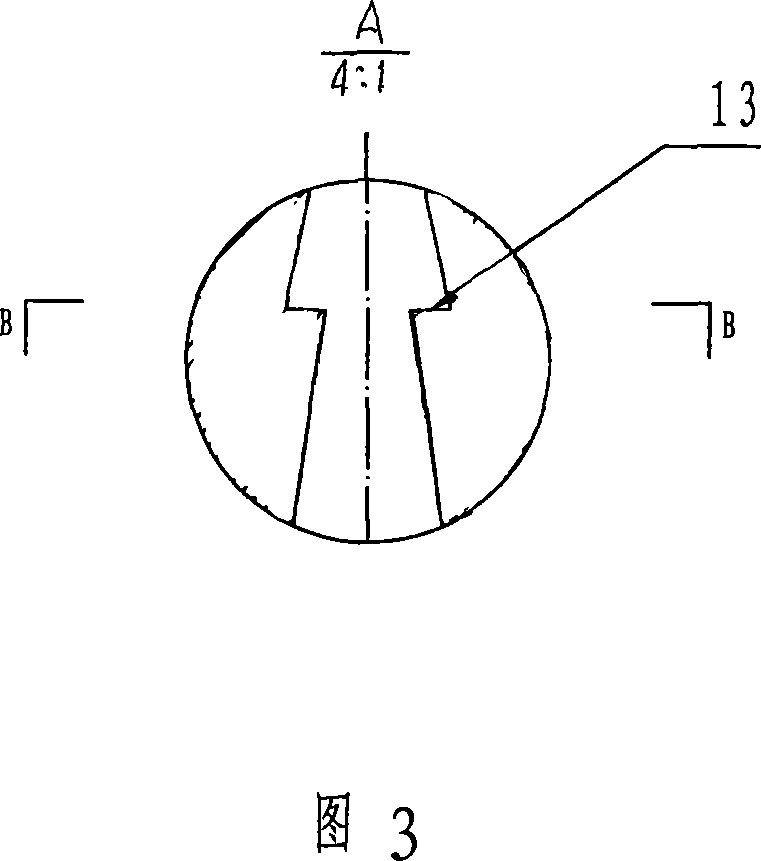

[0025] The water distribution hole 12 of the splash plate 4 around the flat mouth of the device body 5 is 360 degrees from the inside to the outside, and the water distribution hole 12 on the splash plate 4 is strip-shaped, and there are multiple transverse cuts on the left and right sides that are trapezoidal. The water surface 13, in this embodiment, a plurality of water-distrib...

Embodiment 2

[0029] Embodiment 2: As shown in Figure 6, its working process is automatic opening, and it cannot complete the closing action by itself. The water plug 15 under the main shaft 1 is driven by the motor 10 to rotate the gear lock 16. When the 90-degree opening of the gear lock 16 rotates to the ejector rod 17 When the protruding pin 18 is turned on, the push rod 17 falls off. At this time, the water plug 15 is quickly opened and the water is sprayed from the splash plate 4. Its automatic opening and closing mechanism is a snap spring lock switch, and the electric signal output by the fire is controlled by the motor 10. Drive the gear lock 16 to rotate to realize the function.

Embodiment 3

[0030] Embodiment 3: As shown in Figure 7, its working process is automatic opening and closing (opening or closing). The motor 10 uses the gear 20 to drive the rack 19 to reciprocate up and down to open and close the water plug 15 at the bottom of the main shaft 1, which is executed in the event of a fire. Open the opening and closing mechanism 15 to spray water and put out the fire.

[0031] This fire extinguishing device can not be provided with the opening and closing mechanism 6 inside itself, and an electromagnetic valve is set on the front end water supply pipe 11 of the fire extinguishing device 21 in addition. The valve supplies water to extinguish the fire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com