Lens stack assembled in a gas-tight manner for a camera housing

By using a six-degree-of-freedom mechanical calibration unit and an integrated objective lens accommodation device in automotive cameras, combined with precision manufacturing and sealing design, the effects of temperature and moisture on the camera module are solved, and compact, sealed, and high-precision image sensor positioning is achieved. Improved image quality and sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

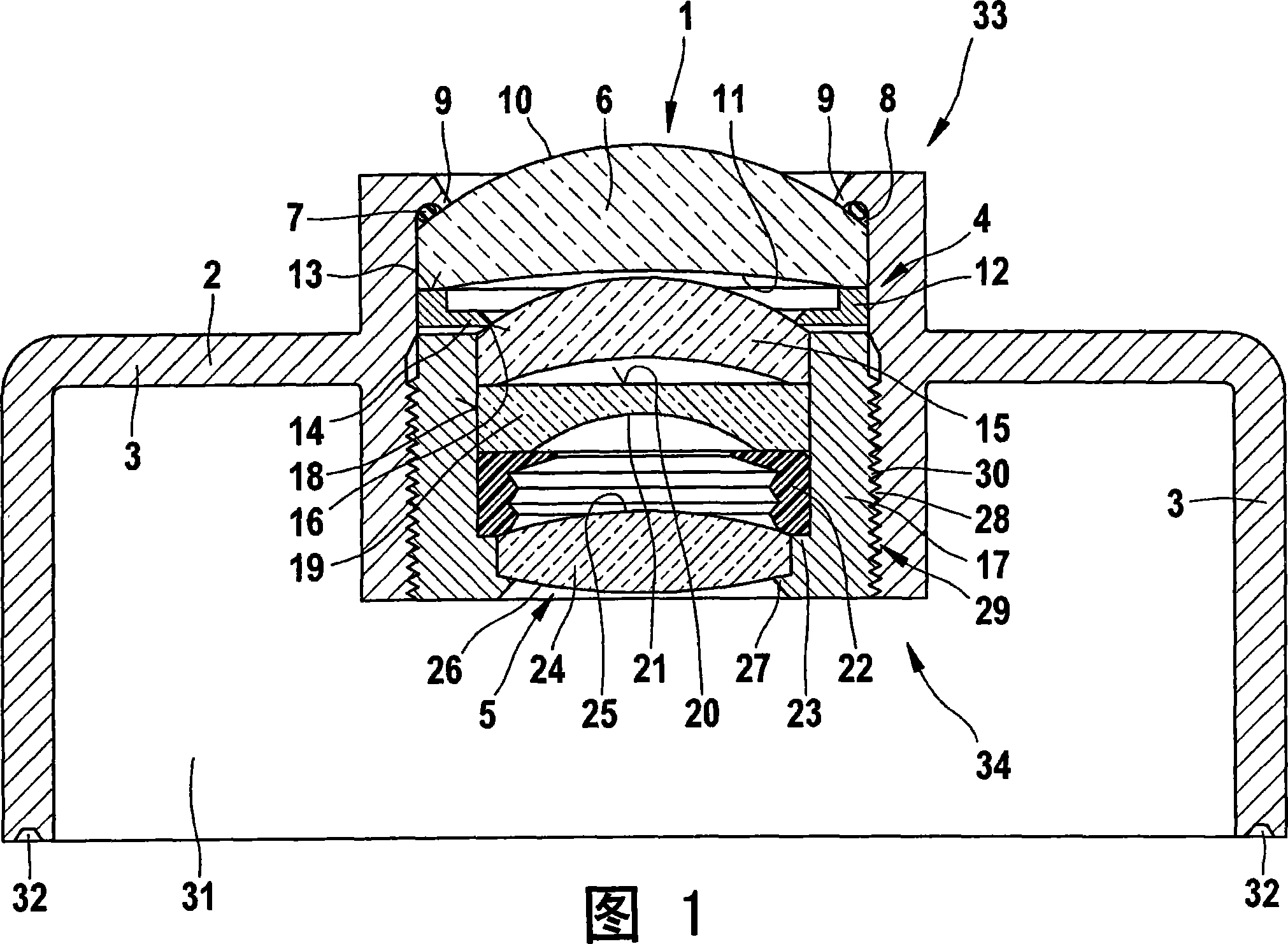

[0013] FIG. 1 shows a front housing 3 of a video camera suitable for automotive applications. The front shell 3 of the housing 2 includes an objective lens holder 4 for accommodating a lens group 5 comprising a plurality of lenses. The lens group 5 is formed as the objective lens 1 of a video camera suitable for automotive applications.

[0014] The lens group 5 includes an outer lens 6 which is sealed relative to the front housing 3 by means of a sealing ring 7 . For this purpose, the front housing 3 has an indentation 8 for the sealing ring 7 . The recess 8 for the sealing ring 7 is formed on the front housing shell 3 in such a way that a bead 9 surrounds the sealing ring 7 , wherein the bead 9 simultaneously forms the contact surface for the outer lens 6 . The outer lens 6 is provided with a convex curvature 10 on its outward side and with a concave curvature 11 on its side facing the interior of the front housing shell 3 . The outer lens 6 is supported on a spacer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com