Cycloaliphatic epoxy (meth)acrylate and preparation method thereof

An epoxy group, carboxylate technology, applied in the direction of organic chemistry, organic chemistry, etc., can solve the problems of poor solubility of organic solvents, inability to obtain corrosion resistance, difficult operation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

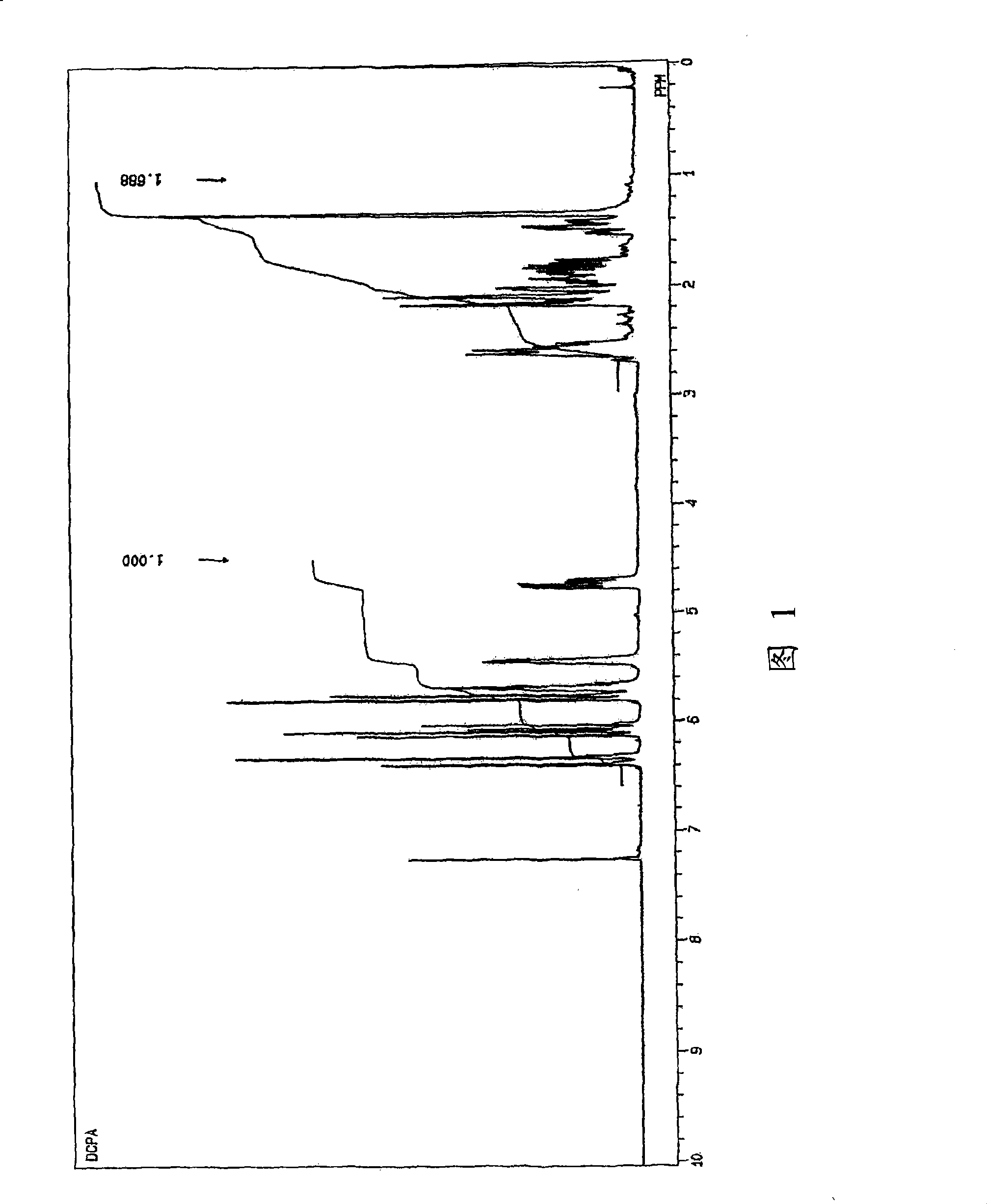

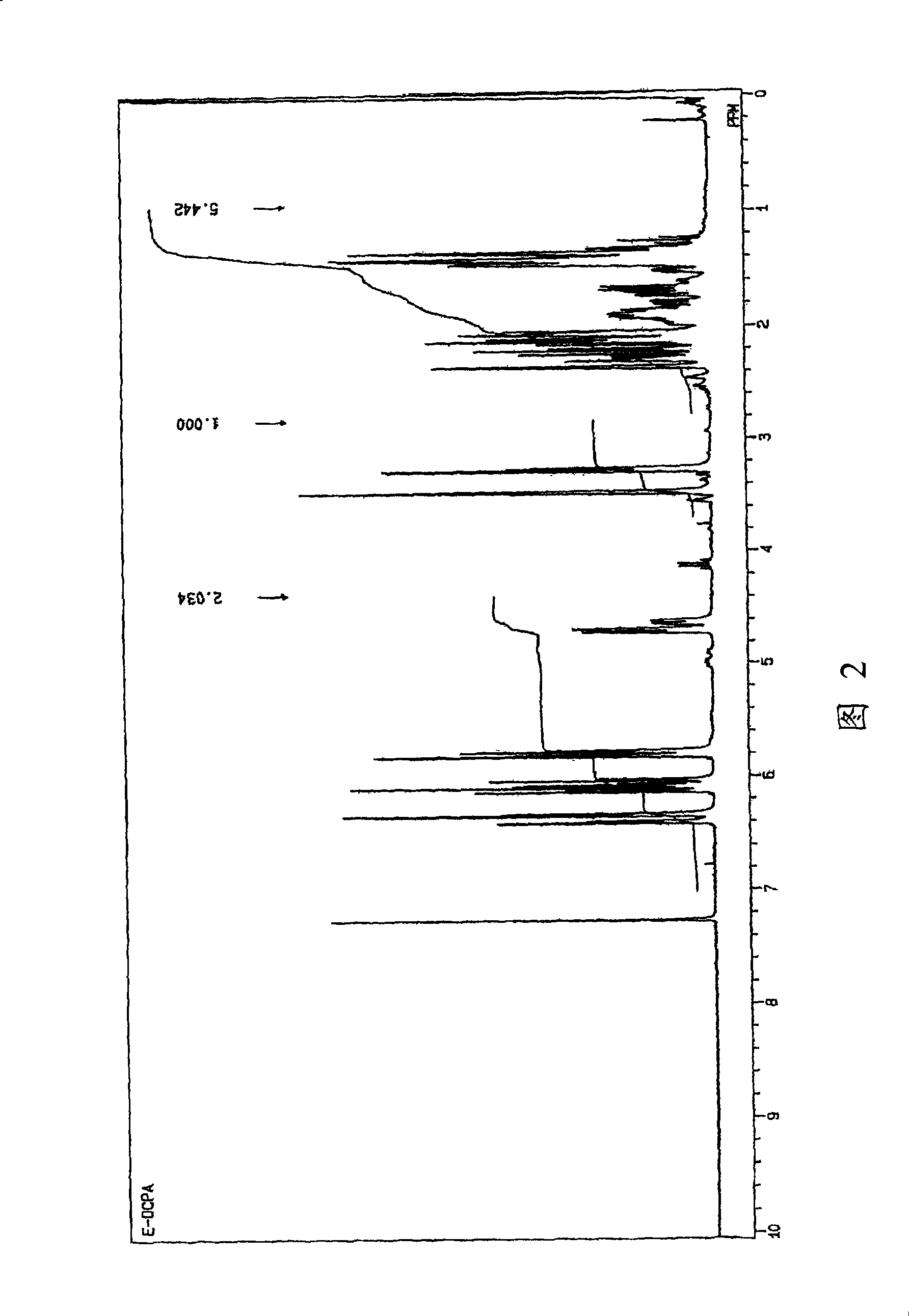

[0146] 100 g of tricyclo[5.2.1.02,6]dec-3-enyl acrylate (manufactured by Hitachi Chemical Industries; trade name "FA-511A"; molecular weight 204.3) was charged in a 1-liter flask with a cannula, and 100g ethyl acetate, make the temperature in the reaction system be 50 ℃ while blowing into air, add the ethyl acetate solution of 156g peracetic acid dropwise (peracetic acid concentration: 29.6%, moisture content: 0.2% ). After the dropwise addition of peracetic acid was completed, aging was carried out at 50° C. for 4 hours to complete the reaction. Then wash the crude reaction solution with water at 50°C, and carry out the operation of removing low boiling point substances at 70°C / 10mmHg to obtain acrylic acid 3,4-epoxytricyclo[5.2.1.0 2,6 ] Decyl ester 91.8g. Its properties are: the oxygen concentration of ethylene oxide is 6.74%, the viscosity is 61cP / 25°C, measured 1 In H-NMR, the peaks from internal double bonds at δ5.5-5.8ppm observed in the spectrum of Figure 1 almost d...

Embodiment 2

[0148] In a 1 liter flask with a cannula, charge 100 g tricycline [5.2.1.0 2,6 ] Dec-3-enyl acrylate (manufactured by Hitachi Chemical Industries; trade name "FA-511A"; molecular weight 204.3), 100 g of toluene, 0.24 g of phosphoric acid, 4.65 g of trimethyloctyl ammonium chloride, 6.60 g of sodium tungstate , blowing in air, the temperature in the reaction system was set to 30° C., and 83.5 g of 30% hydrogen peroxide was added dropwise over about 1 hour. After completion of the hydrogen peroxide dropwise addition, aging was carried out at 40° C. for 2 hours to complete the reaction. Then wash the crude reaction solution with water at 40°C, and carry out the operation of removing low boiling point substances at 70°C / 10mmHg to obtain acrylic acid 3,4-epoxytricyclo[5.2.1.0 2,6 ] Decyl ester 91.6g. Its properties are: the oxygen concentration of ethylene oxide is 6.62%, and the viscosity is 103cP / 25°C. 1 In H-NMR, the peaks from internal double bonds at δ5.5-5.8ppm observed in...

Embodiment 3

[0150] 100 g of methacrylic acid 2-(tricyclo[5.2.1.0 2,6 ]dec-3-enyl)oxyethyl ester (manufactured by Hitachi Chemical Industries; trade name "FA-512MT"; molecular weight 262), and 20 g of ethyl acetate, and the temperature in the reaction system was 50° C. while blowing in air, An ethyl acetate solution of 106.4 g of peracetic acid (concentration of peracetic acid: 29.6%, water content: 0.2%) was added dropwise over about 1 hour. After the dropwise addition of peracetic acid was completed, aging was carried out at 50° C. for 4 hours to complete the reaction. Then at 50°C, the reaction crude liquid was washed with water, and the operation of removing low boiling point substances was carried out at 70°C / 10mmHg to obtain methacrylic acid 2-(3,4-epoxytricyclo[5.2.1.0 2,6 ] Decyloxy) ethyl ester 96.0g. Its properties are: the oxygen concentration of ethylene oxide is 5.20%, and the viscosity is 144cP / 25°C. 1 In H-NMR, the peaks from internal double bonds at δ5.5-5.8ppm observed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com