Roller parameter automatic calculating method for three-roller planetary rolling mill

A planetary rolling mill, automatic calculation technology, applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of waste of raw materials and processing experiment costs, fluctuations in the wall thickness of copper pipe products, and reduce the yield of products, so as to reduce the rolling Control force, realize arbitrary adjustment and change, and improve the effect of export speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

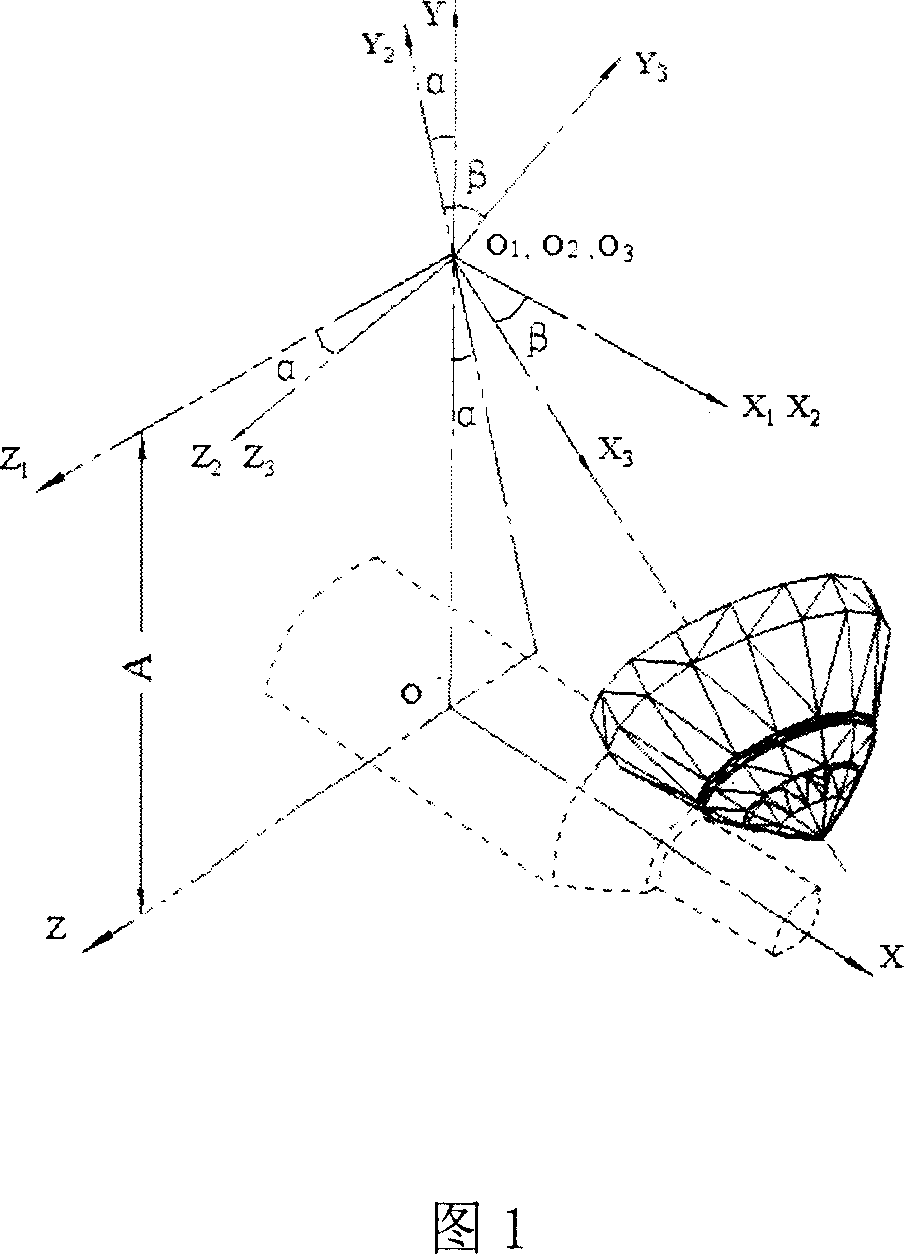

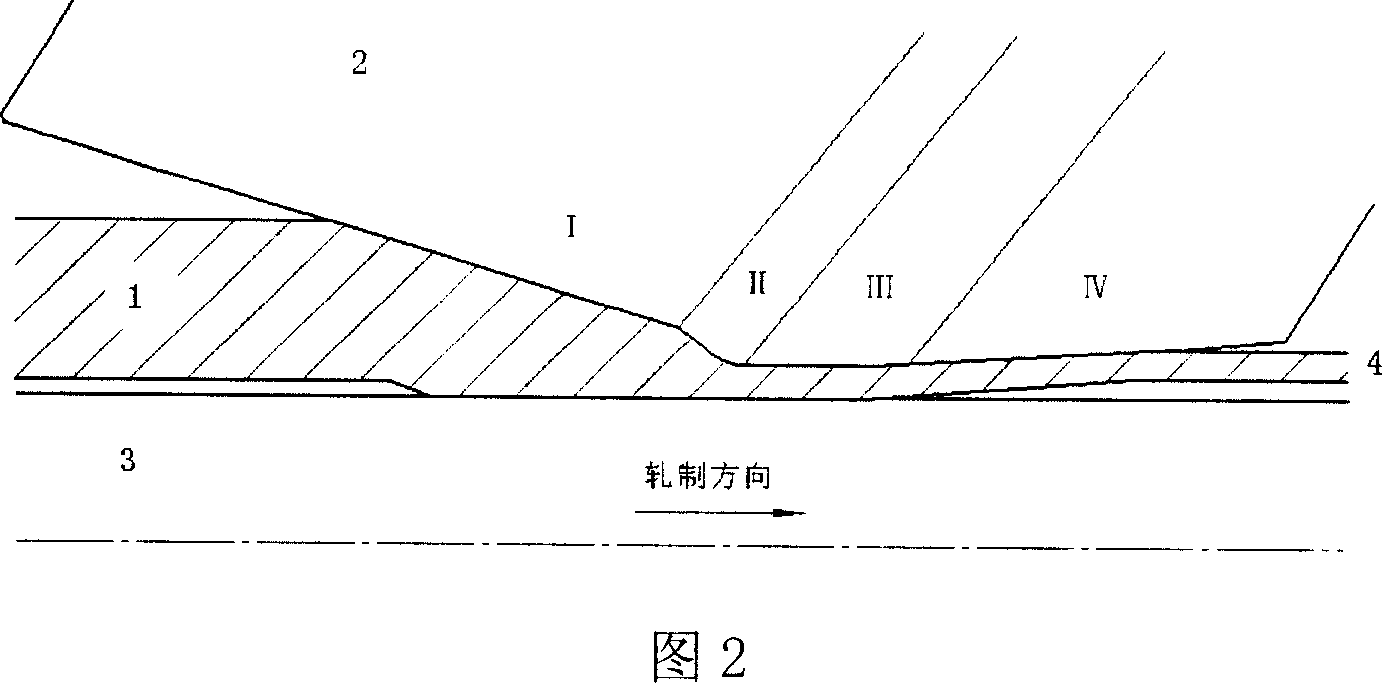

[0020] Schematic diagram of each zone in the longitudinal section of a three-roll planetary rolling mill 3 , Roll deflection angle α and inclination angle β. In order to keep the diameter of the rolled piece at the flat zone III basically the same, it is necessary to find the semi-cone angle θ of the roll flat zone III 3 and the matching relationship between the roll deflection angle α and the inclination angle β, it can be seen that the semi-cone angle θ of the roll smoothing zone III 2 The computational design of has very high practical value.

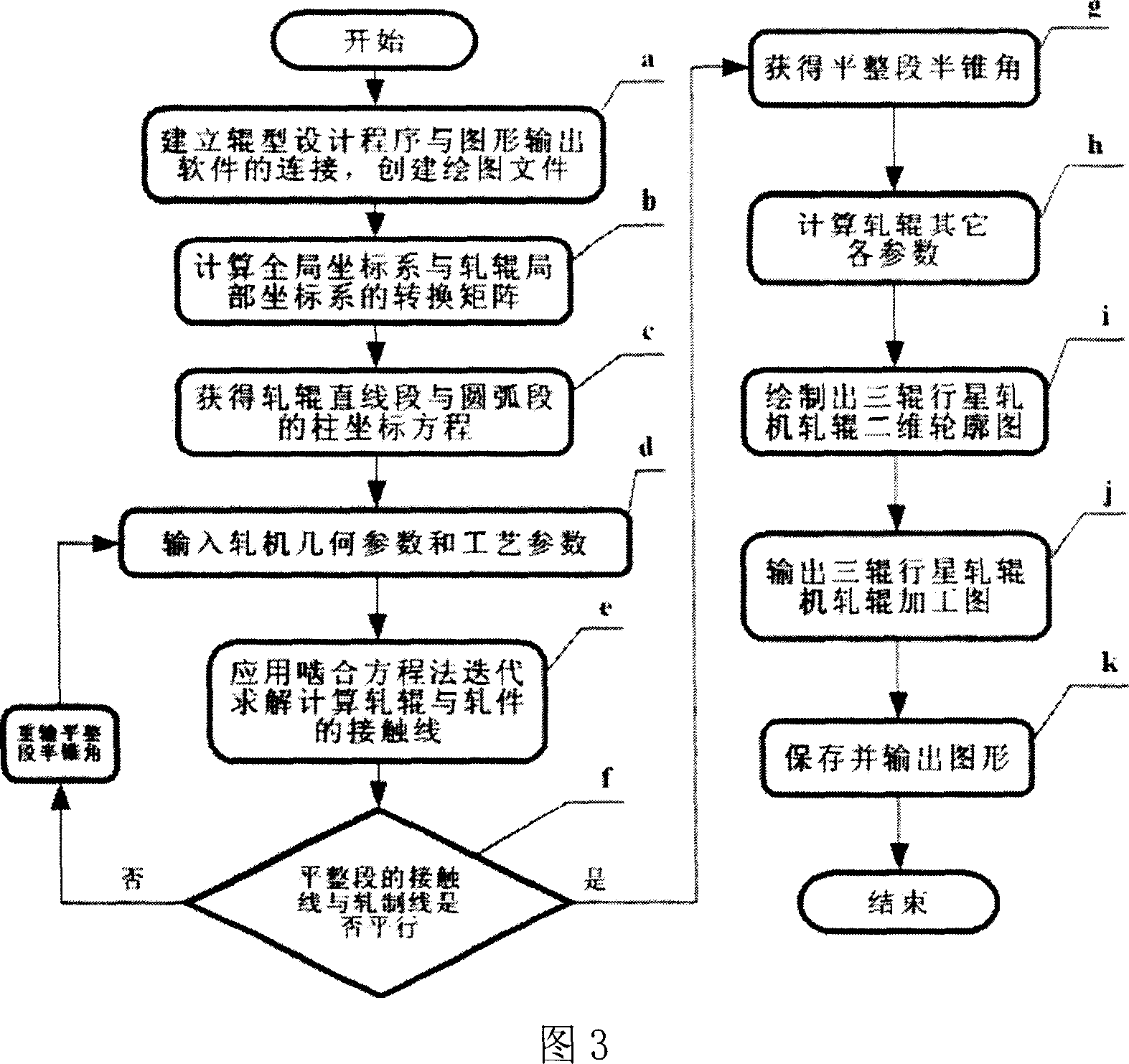

[0021] Fig. 3 is a flow chart of the automatic calculation method of the roll profile. Since the rolls of the three-high planetary rolling mill have a certain inclination angle β and deflection angle α, the spatial geometric relationship is complex, so to accurately ensure that the roll smoothing zone III is parallel to the rolling line, it is necessary to use a reasonable and effective mathematical calculation method, and at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com