Method of manufacturing disposable wearing article

A manufacturing method and article technology, applied in the field of manufacturing disposable wearing articles, capable of solving the problems of inconsistent shape of the front waist region 522, dislocation or skew of the annular belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The details of the manufacturing method of the disposable wearing article of the present invention are described below with reference to the accompanying drawings.

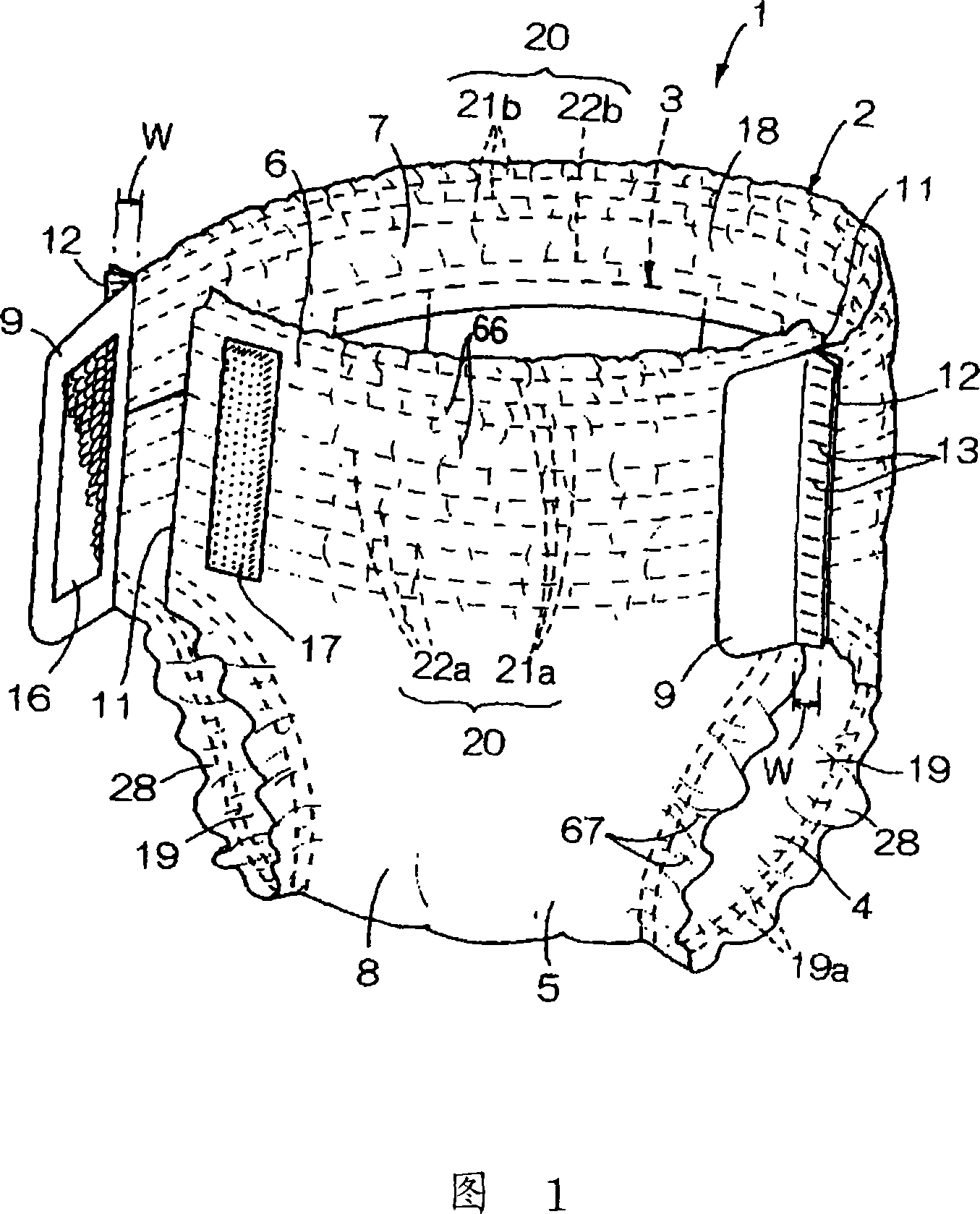

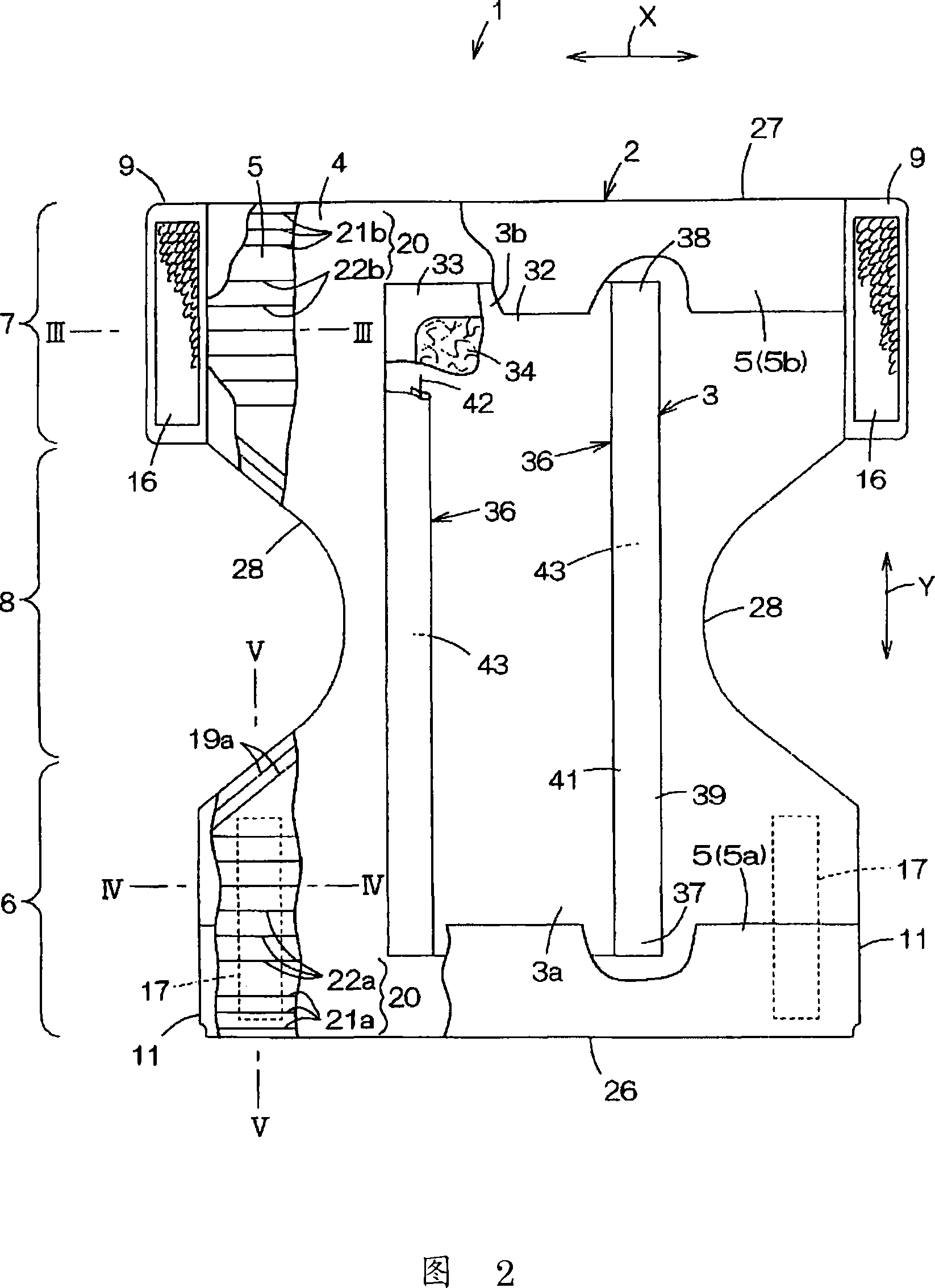

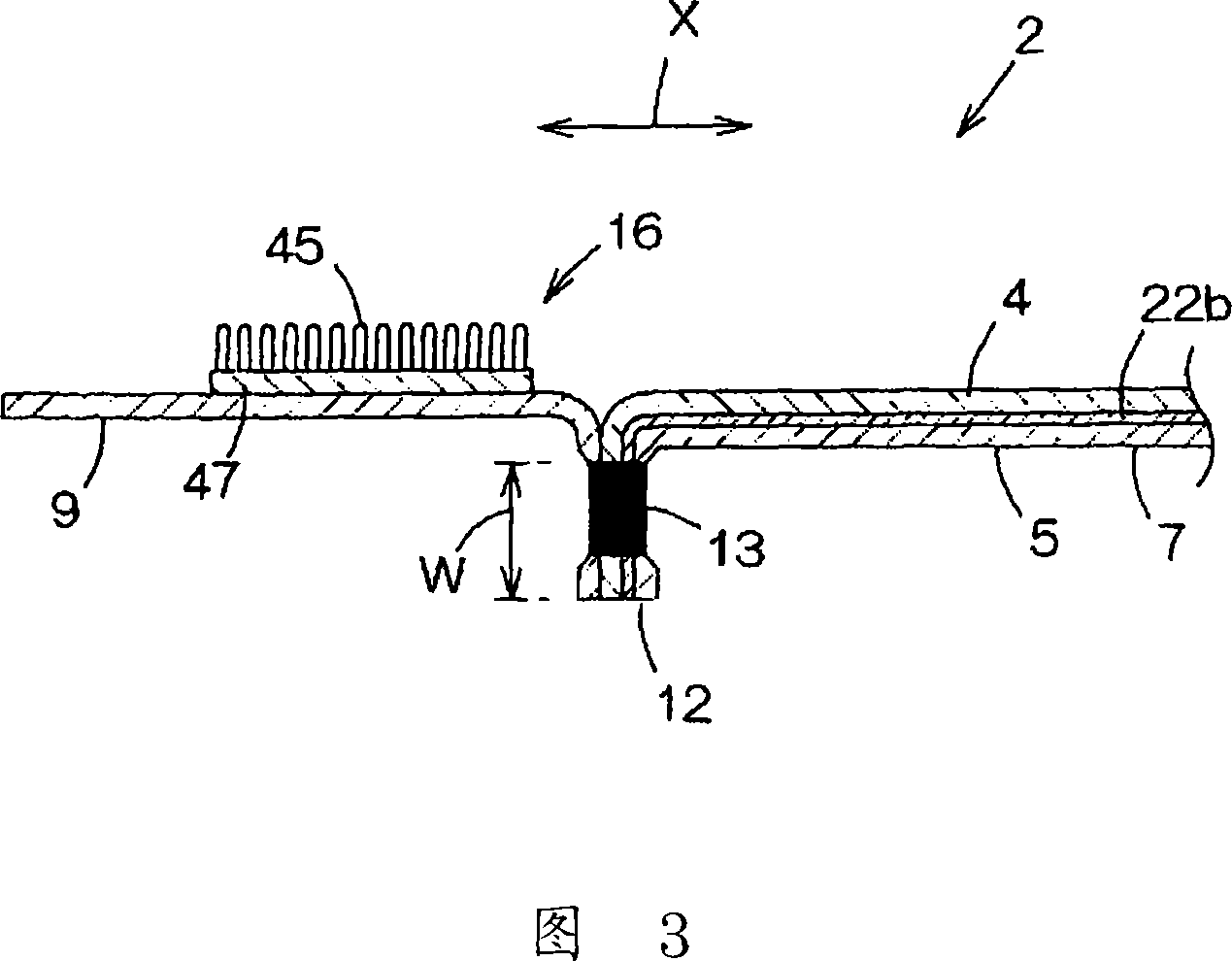

[0078] The disposable pull-on diaper 1 shown in the perspective view of FIG. 1 is manufactured by the manufacturing method of this invention, and has the body covering part 2 and the body fluid absorbing part 3. As shown in FIG. The body covering portion 2 has a crotch region 8, a front waist region 6 formed near the front of the crotch region 8, and a rear waist region 7 formed near the rear of the crotch region 8. The outer surface sheet 5 facing the worn clothing (not shown) and the inner surface sheet 4 positioned inside the outer surface sheet 5 and facing the skin (not shown) of the diaper wearer are formed. In the vicinity of the two side edges 12 of the back waist region 7, the wings 9, which are formed by the sheets that are separately integrated with the inner and outer surfaces 4, 5, are joined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com