Heat radiator

A technology of heat dissipation device and heat sink, which is applied in the direction of elastic/clamping device, cooling/ventilation/heating transformation, circuit layout on support structure, etc., which can solve the problems of low efficiency, fastening components and high fixed cost of heat sink, etc. Achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

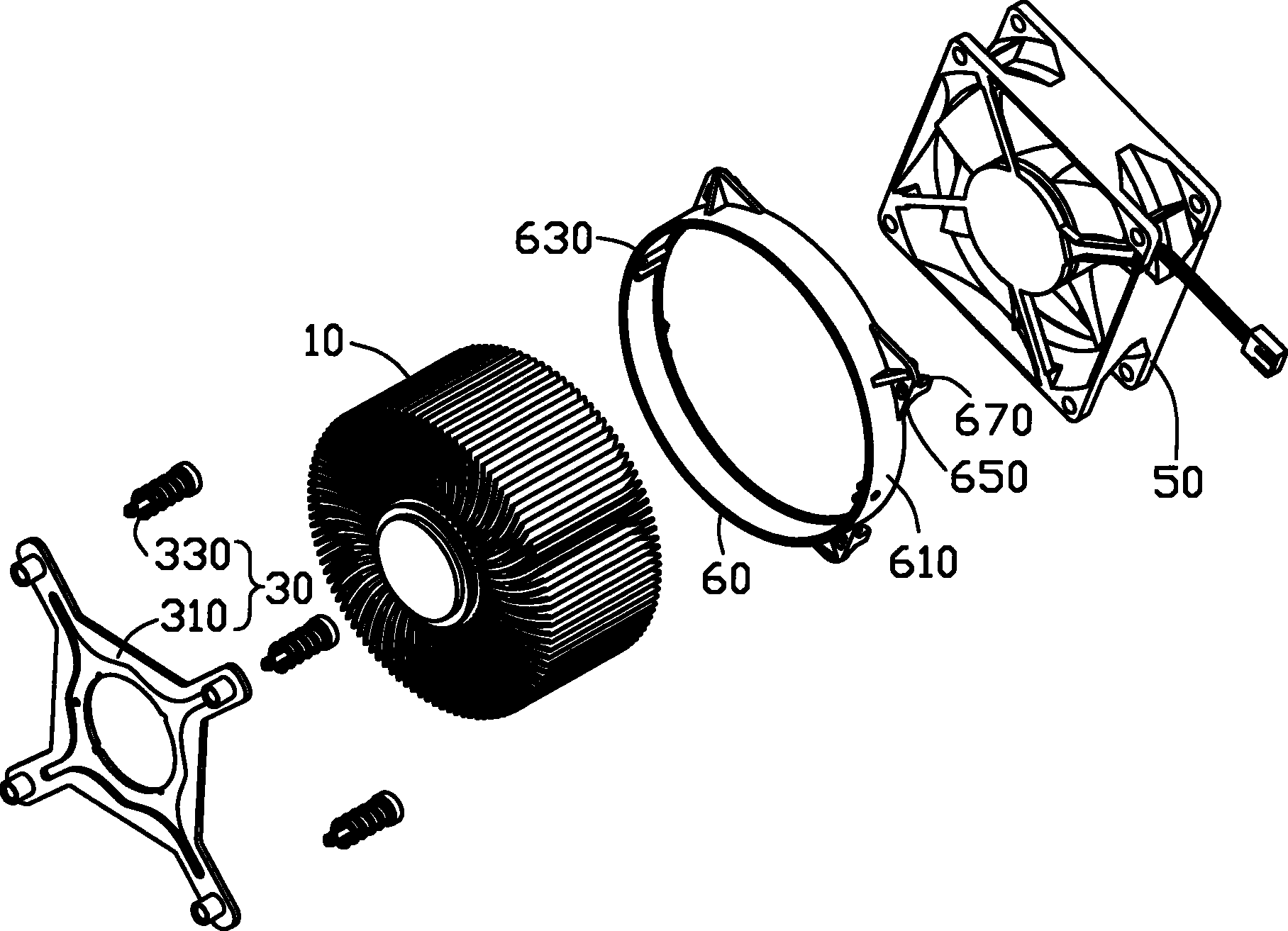

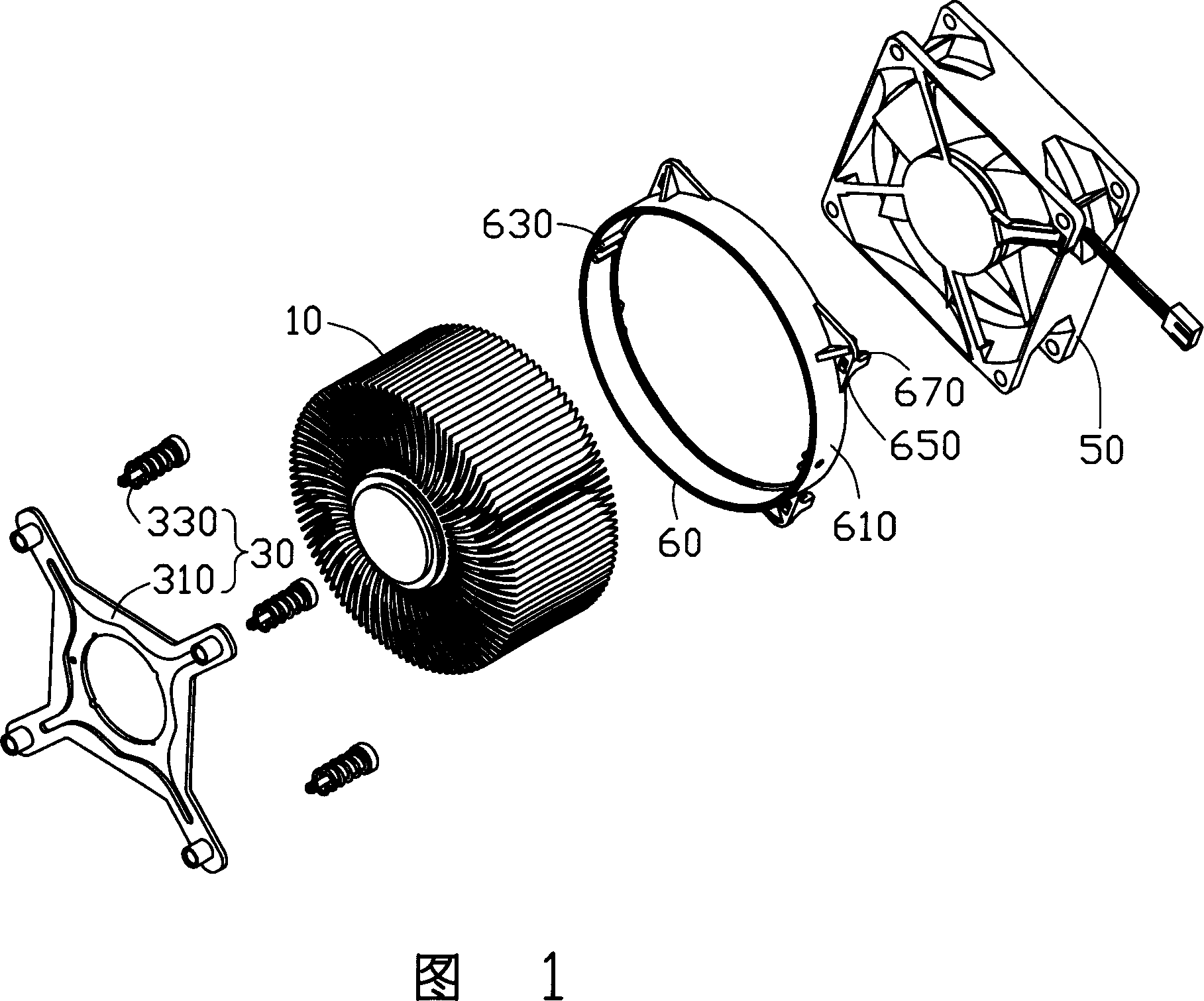

[0015] Please refer to FIG. 1 , the heat dissipation device is used for dissipating heat generated by an electronic component (not shown) mounted on a circuit board (not shown). The heat dissipation device includes a heat sink 10 , a buckle 30 for fixing the heat sink 10 to electronic components, a fan 50 mounted on the heat sink 10 , and a fixing frame 60 for fixing the fan 50 to the heat sink 10 .

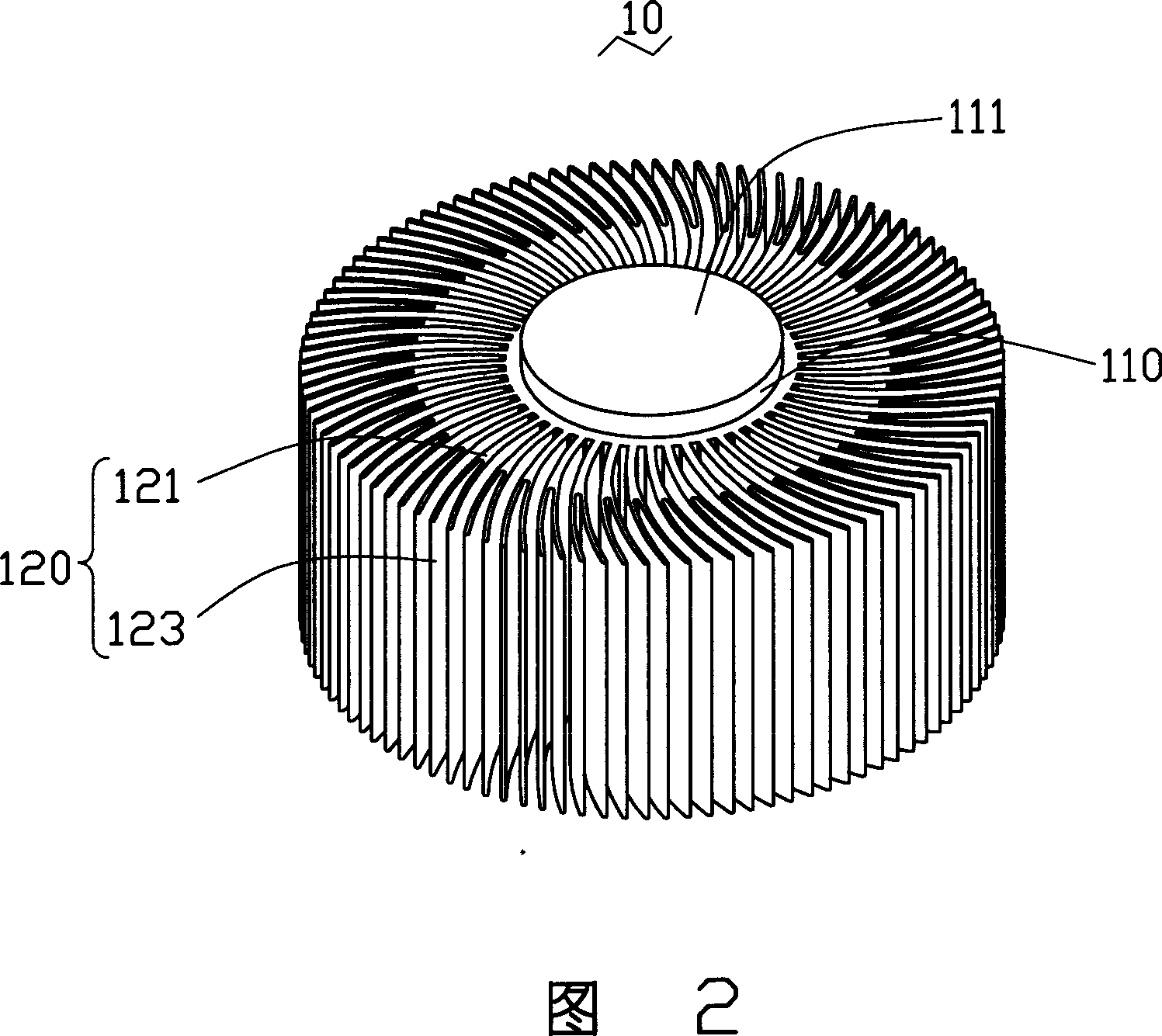

[0016] Please refer to FIG. 2 , the heat sink 10 includes a central cylinder 110 and a plurality of fins 120 radially extending from the outer peripheral surface of the central cylinder 110 . An extension portion 111 is further extended outwardly from the end of the central column 110 along its axial direction. The extension portion 111 protrudes from the fins 120 for contacting the heat-generating electronic components to absorb heat. The plurality of fins 120 are bent in a certain arc along the circumference of the cylinder 110 . Each fin 120 includes a stem portion 121 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com