Honeycomb hook plate for medicine bottle packaging and medicine bottle packaging method

A honeycomb type, hook-and-disk technology, applied in packaging and other directions, can solve the problems of affecting the treatment effect, low work efficiency, drug pollution, etc., and achieve the effects of avoiding pollution, simple structure, and enhancing overall strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

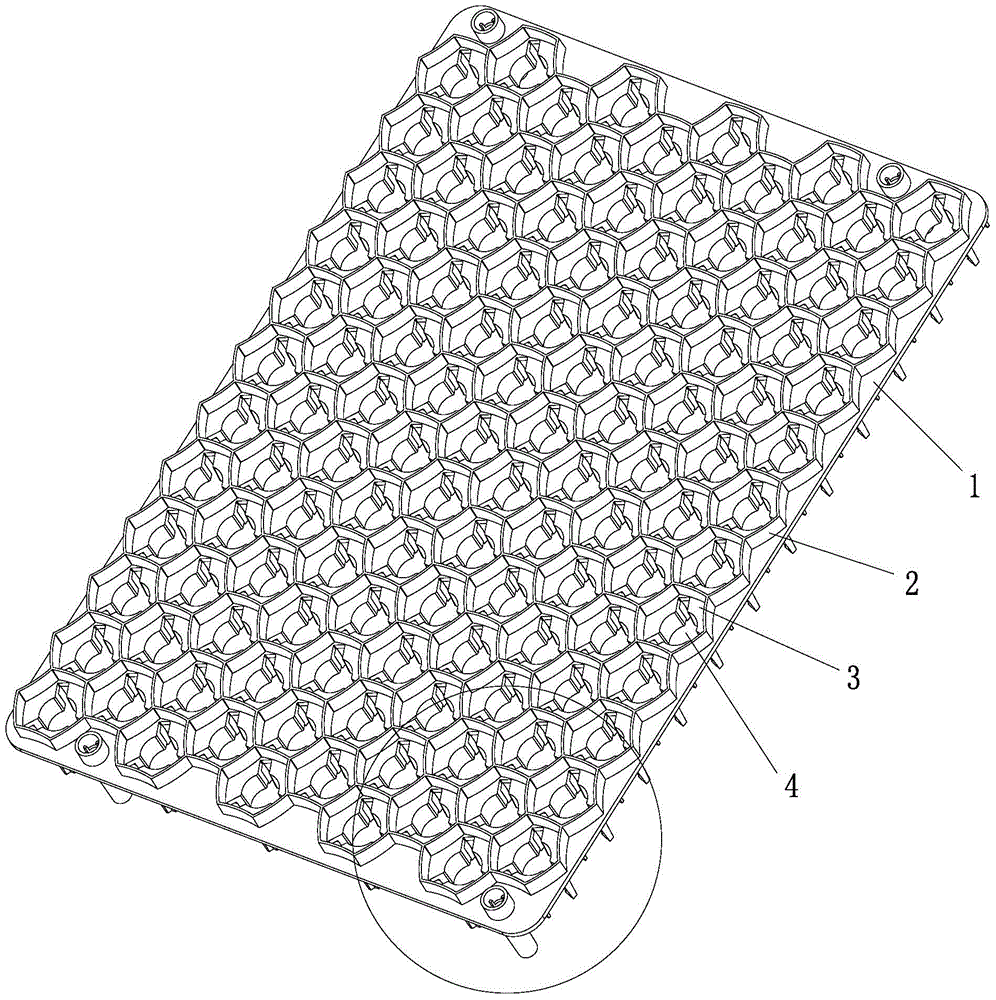

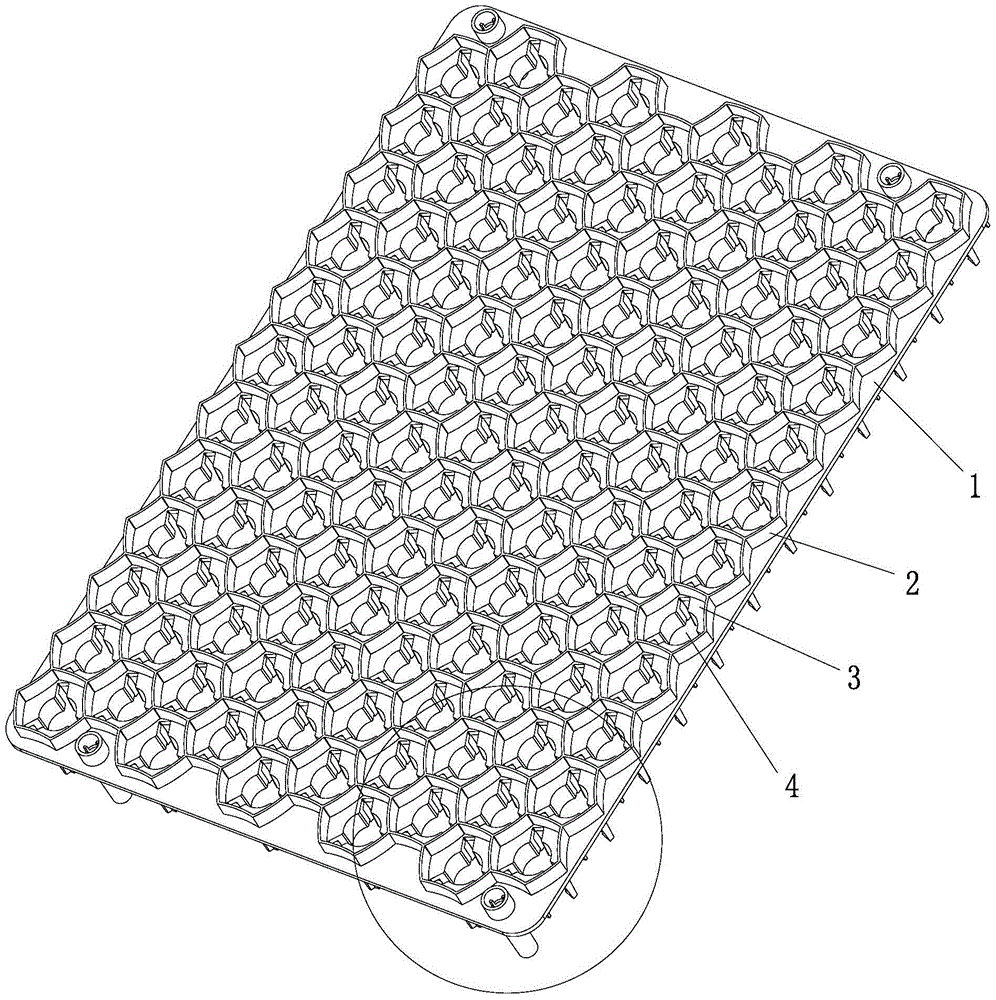

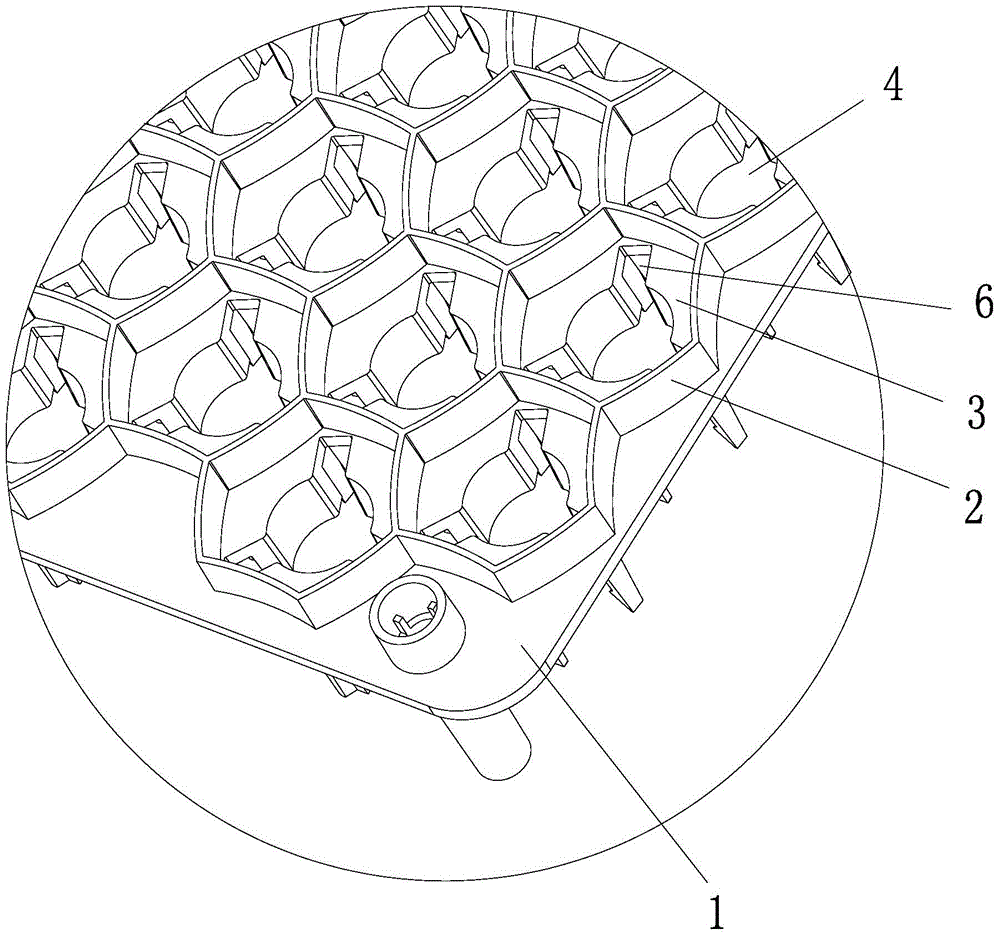

[0028] Example: as shown in the figure 1 to figure 4 As shown, a honeycomb hook plate for medicine bottle packaging, including a plate body 1 , the disc body 1 The upper part is protruded with convex ribs arranged in a honeycomb shape 2 , convex rib 2 beehives 3 inner plate 1 center opening 4 And opening 4 The perimeter extends downwards to form ribs 51 Docking part 5 , the opening 4 There are three extended split slots at intervals in the circumferential direction 6 , each opening 4 fork slot 6 The end of the bottle extends downward to form a set of elastic barbs that match the bottle cap 7 , in this example, each group of elastic barbs 7 It is composed of three spaced elastic barbs, the hook plate and the bottle cap 8 When assembled and matched, the upper end of the bottle cap is set against the corresponding opening 4 lower docking part 5 At the lower end, the hook plate passes through the corresponding set of ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com