A pulse width adjustable laser

A laser and pulse width technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of high cost, large loss, energy waste, etc., and achieve the effect of easy installation and debugging, and easy engineering promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

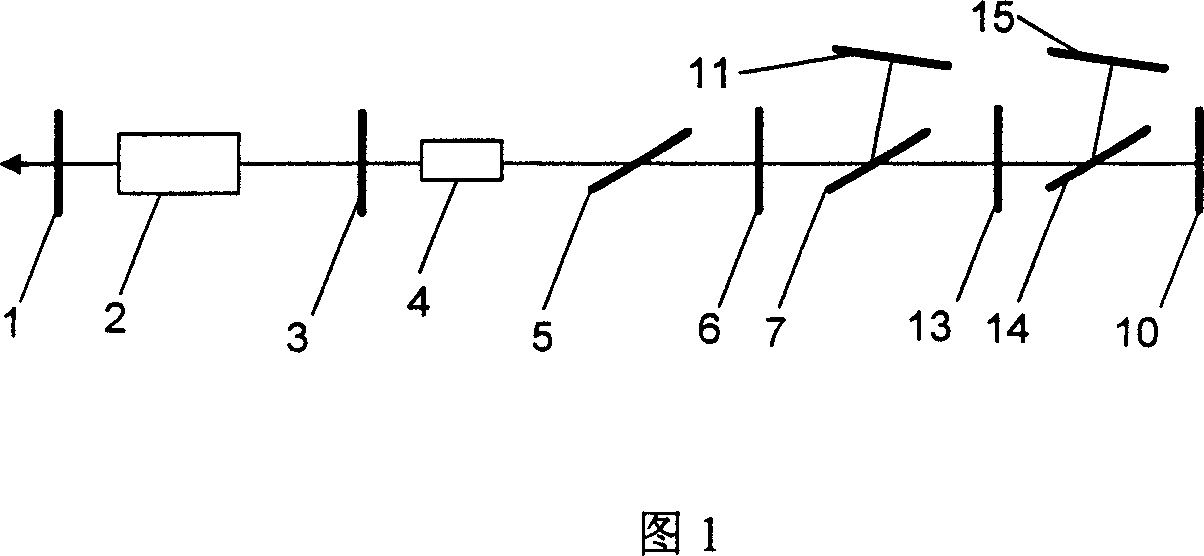

[0032] Referring to Figure 1, an electro-optic Q-switched pulse-width tunable laser is produced, including an output mirror 1, a laser rod 2, a quarter wave plate 3, a boosted electro-optic Q-switched Pockels cell 4, a first polarizer 5, and a first polarizer. A 1 / 2 wave plate 6, a second polarizer 7, a third 1 / 2 wave plate 13, a fourth polarizer 14, a first total mirror 10, a second total mirror 11, and a third total mirror 15. A second total-reflection mirror 11 is provided on one side of the polarizing plate 7, and the second total-reflection mirror 11 is used to reflect all the laser light reflected by the polarizing plate 7 back along the original path; the 1 / 2 wave plate is Movable, able to be removed or inserted into the optical path. The plane of the 1 / 2 wave plate is perpendicular to the laser light path. The polarization directions of all the polarizers are parallel, and the optical axis of all the 1 / 2 wave plates forms an angle of 45° with the polarization direction of ...

Embodiment 2

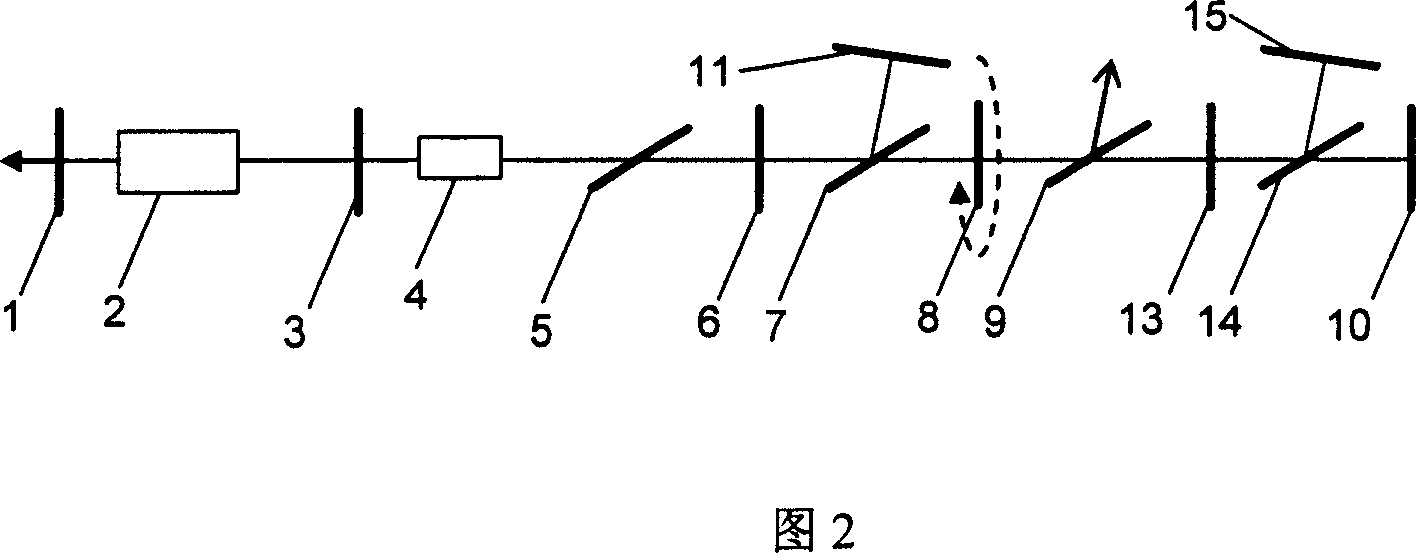

[0036] As shown in Fig. 2, a set of 1 / 2 wave plate 8 and polarizer 9 are inserted into the resonant cavity, and the 1 / 2 wave plate 8 can be rotated. When the light pulse oscillates in the resonant cavity determined by the mirror 15 or 11, by rotating the 1 / 2 wave plate 8, a certain range of pulse width adjustment can be achieved. The rotation of the 1 / 2 wave plate 8 can be achieved manually or electrically, which is easy for those skilled in the art to do. Others are the same as in Example 1.

Embodiment 3

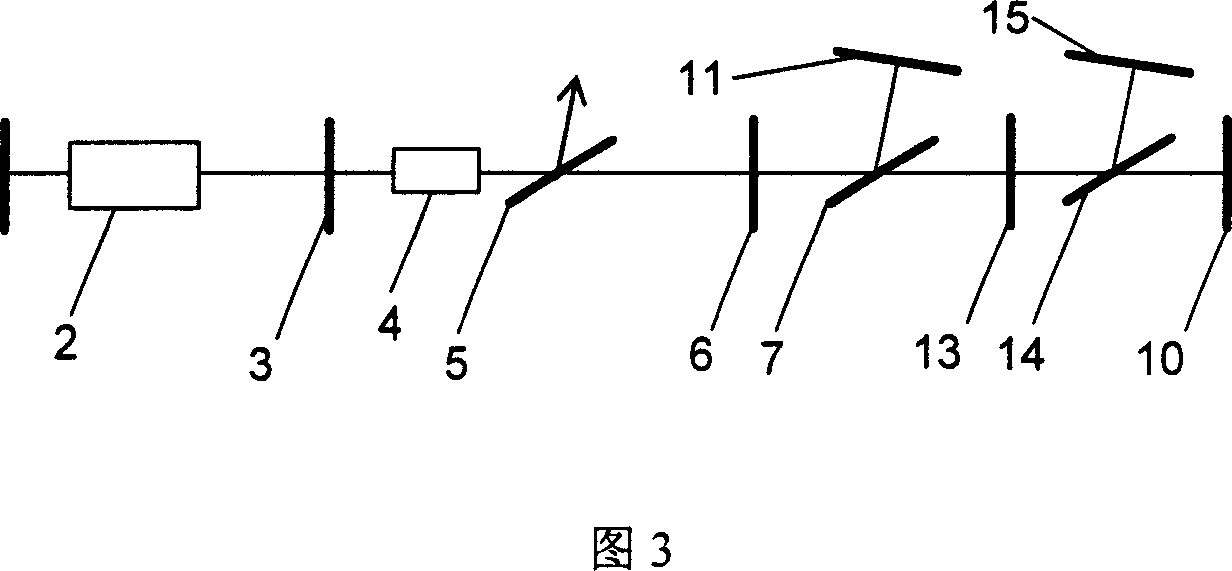

[0038] Embodiments 1 and 2 both use boost type electro-optic Q-switched Pockels cell 4, if a step-down type is used, the quarter-wave plate 3 in embodiment 2 needs to be removed. Others are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com