Automatic collection method for mechanical processing task progress state based on machine tool power information

A power information and machining technology, applied in the fields of communication and machinery manufacturing, can solve problems such as affecting the efficiency of enterprise information system, untimely data feedback, and error-prone manual statistics, so as to solve the problem of automatic collection, increase efficiency, collect method stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Specific examples of automatic collection of progress status of batch processing machining tasks:

[0036] Processing workpiece: a motorcycle part

[0037] Machine tool: CKA6140

[0038] Sensor: WBQ212P71

[0039] Terminal: iTouch121A(-T) embedded information terminal

[0040] Analog / digital converter: HTK-NDC1 Ethernet field measurement and control server

[0041] Three working steps: ① Cutting the outer circular surface

[0042] ②Cutting end face

[0043] ③Cutting end face

[0044] In the drive system where the frequency converter drives the asynchronous motor, the batch processing machining task progress state collection process is shown in Figure 3, ① the present invention uses the power sensor to collect the power information output by the frequency converter; ② the sensor outputs 0~5V analog voltage signal , and output to the A / D converter for analog-to-digital conversion to obtain a digital signal; ③A / D converter sends the digital signal...

Embodiment 2

[0046] Specific examples of automatic collection of progress status of single-piece machining machining tasks:

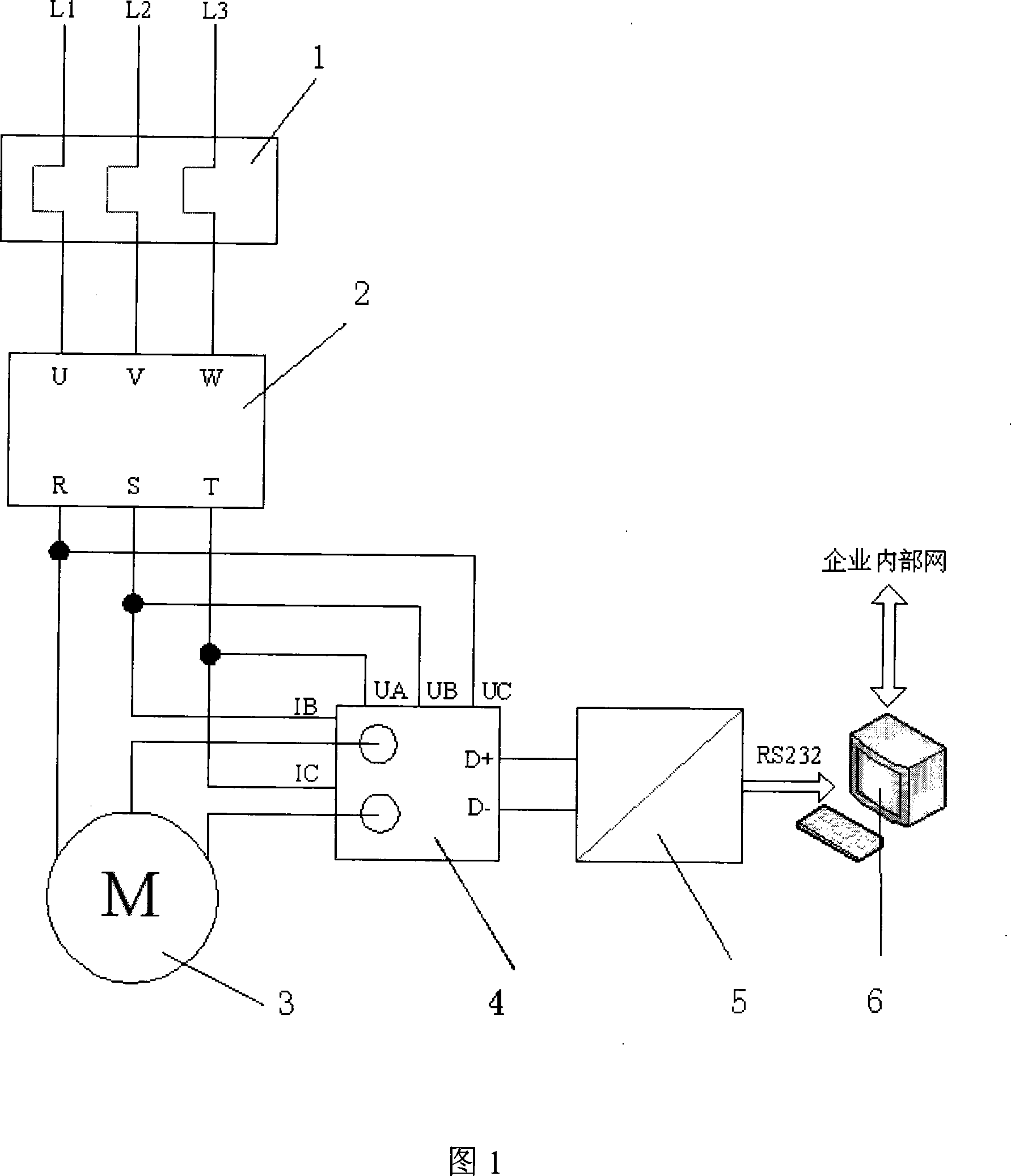

[0047] The hardware connection diagram is the same as batch processing, as shown in Figure 1. In the driving system of the asynchronous motor driven by the frequency converter, the progress status collection process of the single-piece machining machining task is shown in Figure 4. Its data acquisition method is the same as batch processing. The terminal automatic collection method is:

[0048] ① Before processing, it is found that the no-load database does not exist, start the machine tool, use different speeds, and obtain the no-load power at all speeds to form a no-load power database; ③ Add the theoretical cutting power and the no-load power at the corresponding speed to obtain the theoretical power curve; ④ When the workpiece is processed, obtain the power curve of the main motor of the machine tool, and compare the proportion of the actual power curve in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com