Microelectronic machinery microwave frequency detector and its preparation method

A micro-electromechanical, microwave frequency technology, applied in the direction of frequency measurement devices, frequency to phase shift conversion, etc., can solve the problems of small signal amplitude, DC power consumption, etc., and achieve the effect of improving the dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

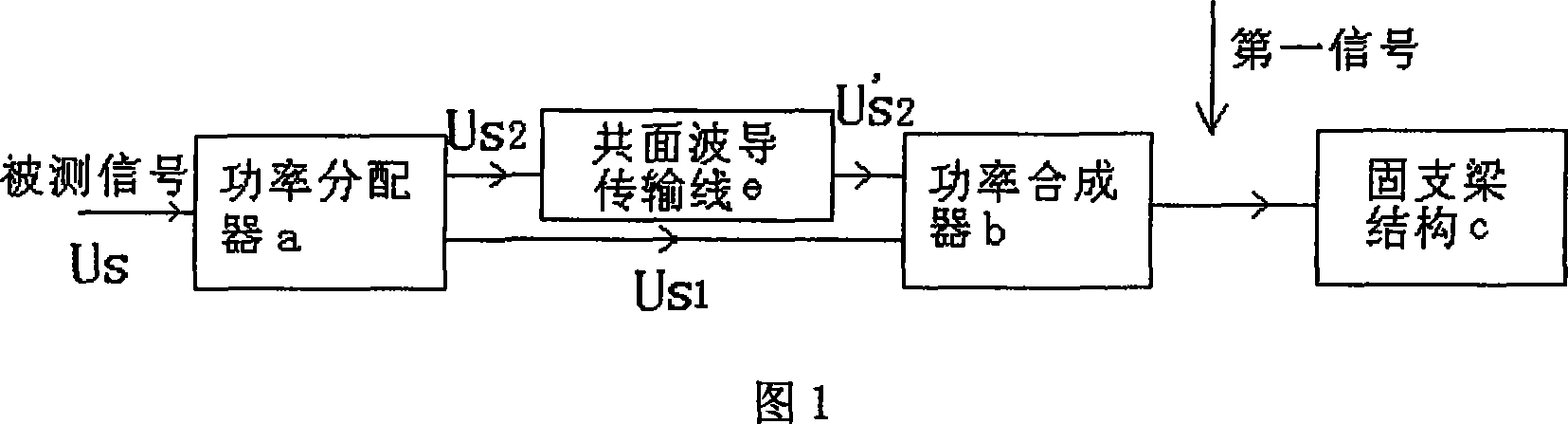

[0036] Micro-electromechanical microwave frequency detector of the present invention is a kind of microwave instantaneous frequency on-line detector, is substrate with GaAs substrate, and specific embodiment is as follows:

[0037] A power divider a, a power combiner b, a coplanar waveguide transmission line e, and a fixed beam structure c are arranged on the substrate 1:

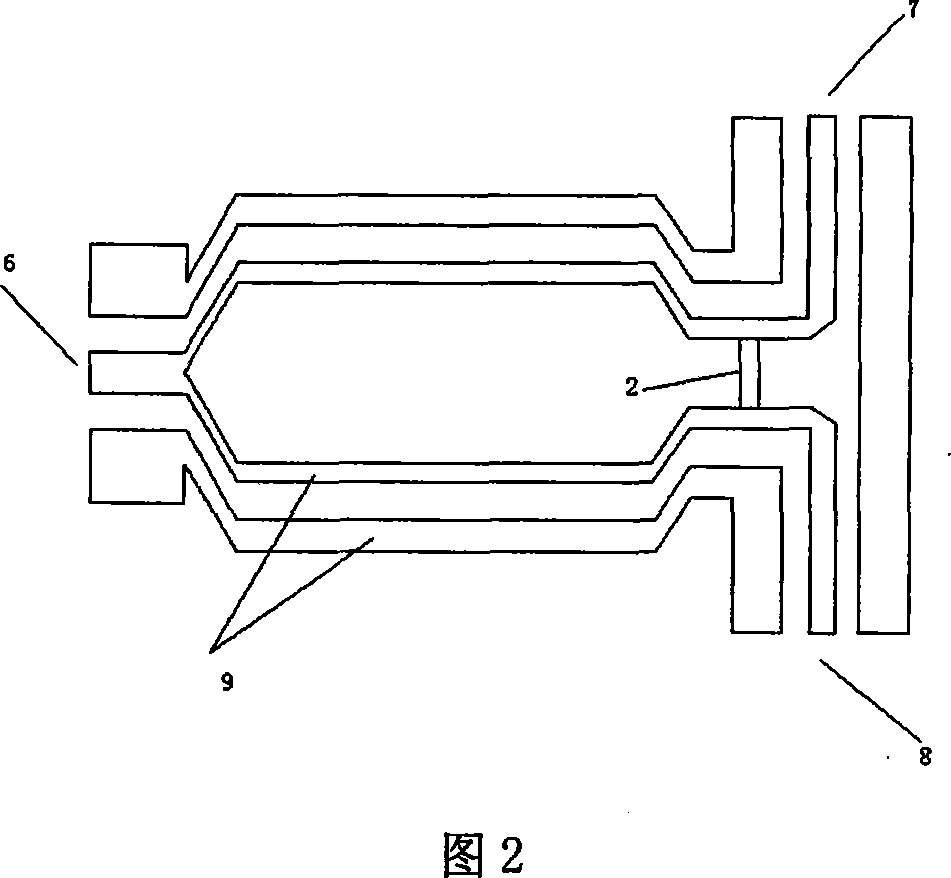

[0038] Power divider a and power combiner b are composed of port one 6, port two 7, port three 8, asymmetric coplanar stripline 9, and tantalum nitride resistor 2 composed of coplanar waveguides. Port one 6 passes through asymmetric coplanar Strip lines 9 are respectively connected to port two 7 and port three 8, and a tantalum nitride resistor 2 is connected between two asymmetric coplanar strip lines 9 connected to port two 7 and port three 8;

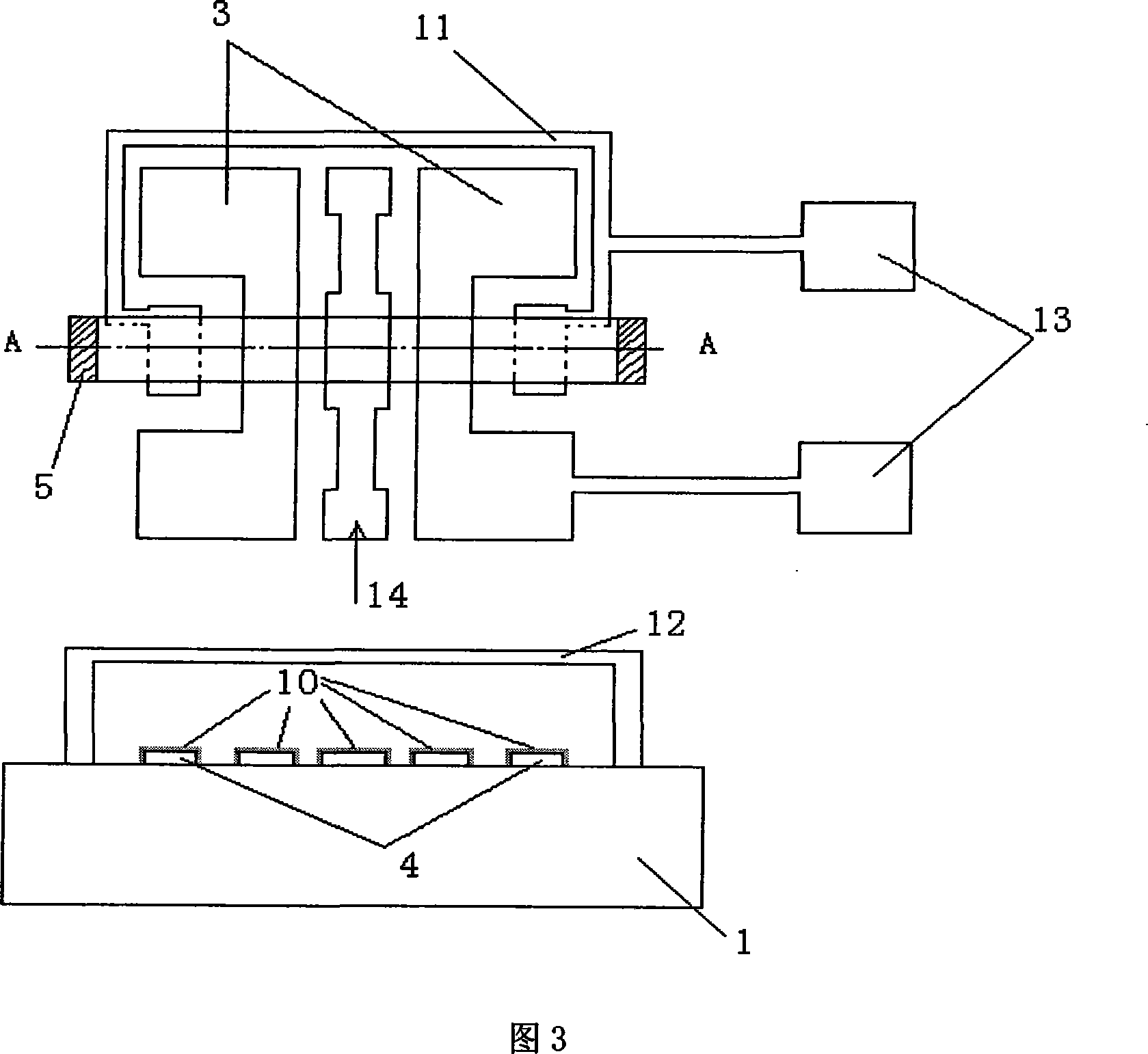

[0039] The fixed-support beam structure c is lined with gallium arsenide 1, and a CPW signal line 14 is provided in the middle of the substrate 1, and CPW ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com