Method of constructing steel house for uniformizing hot environment therein

A technology for steel structures and buildings, applied in building structures, buildings, building components, etc., can solve problems such as short residential life, moisture on wooden components, and rust on metal components, and achieve the purpose of suppressing temperature unevenness and eliminating temperature differences. The effect of averaging and reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

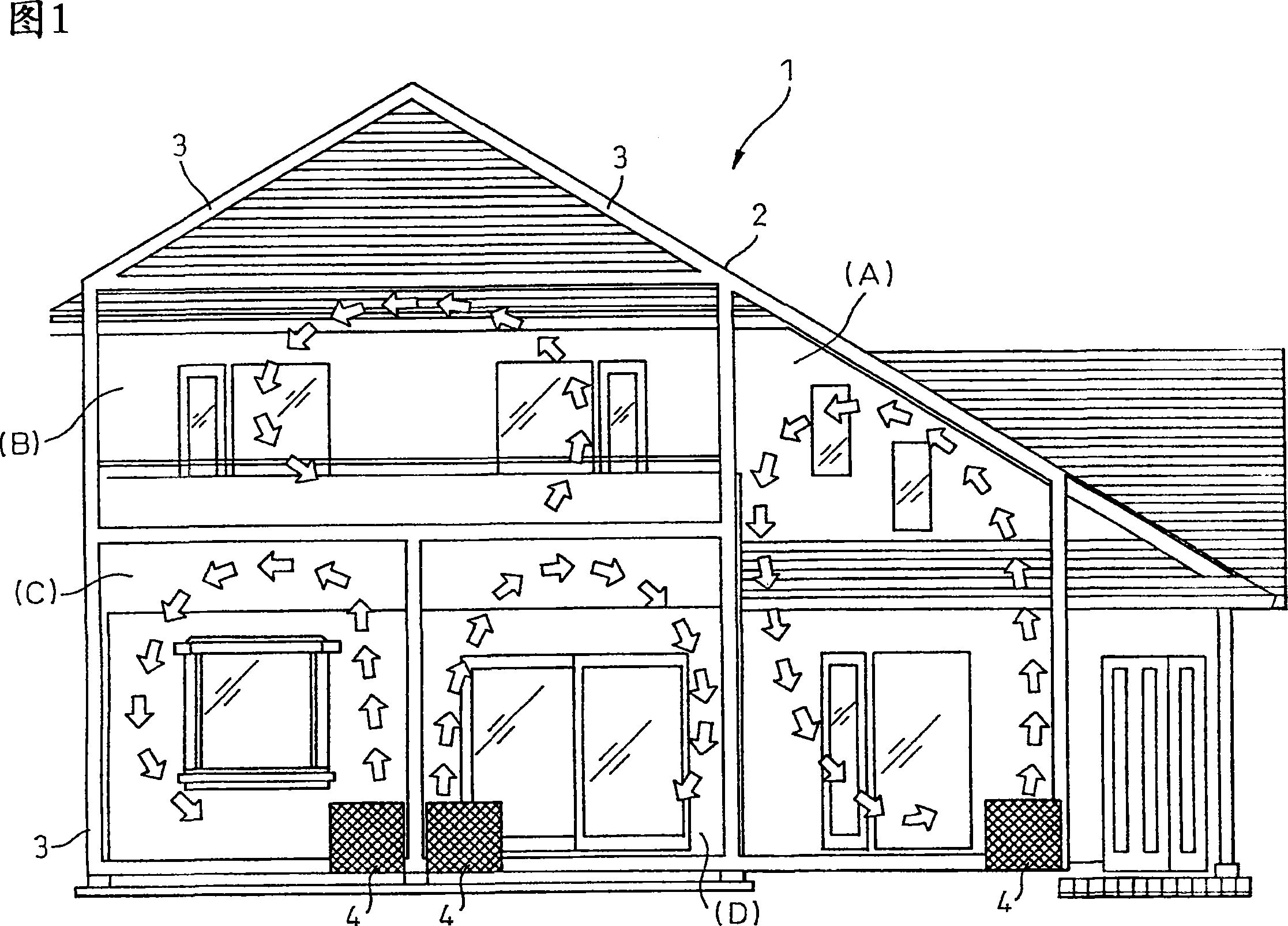

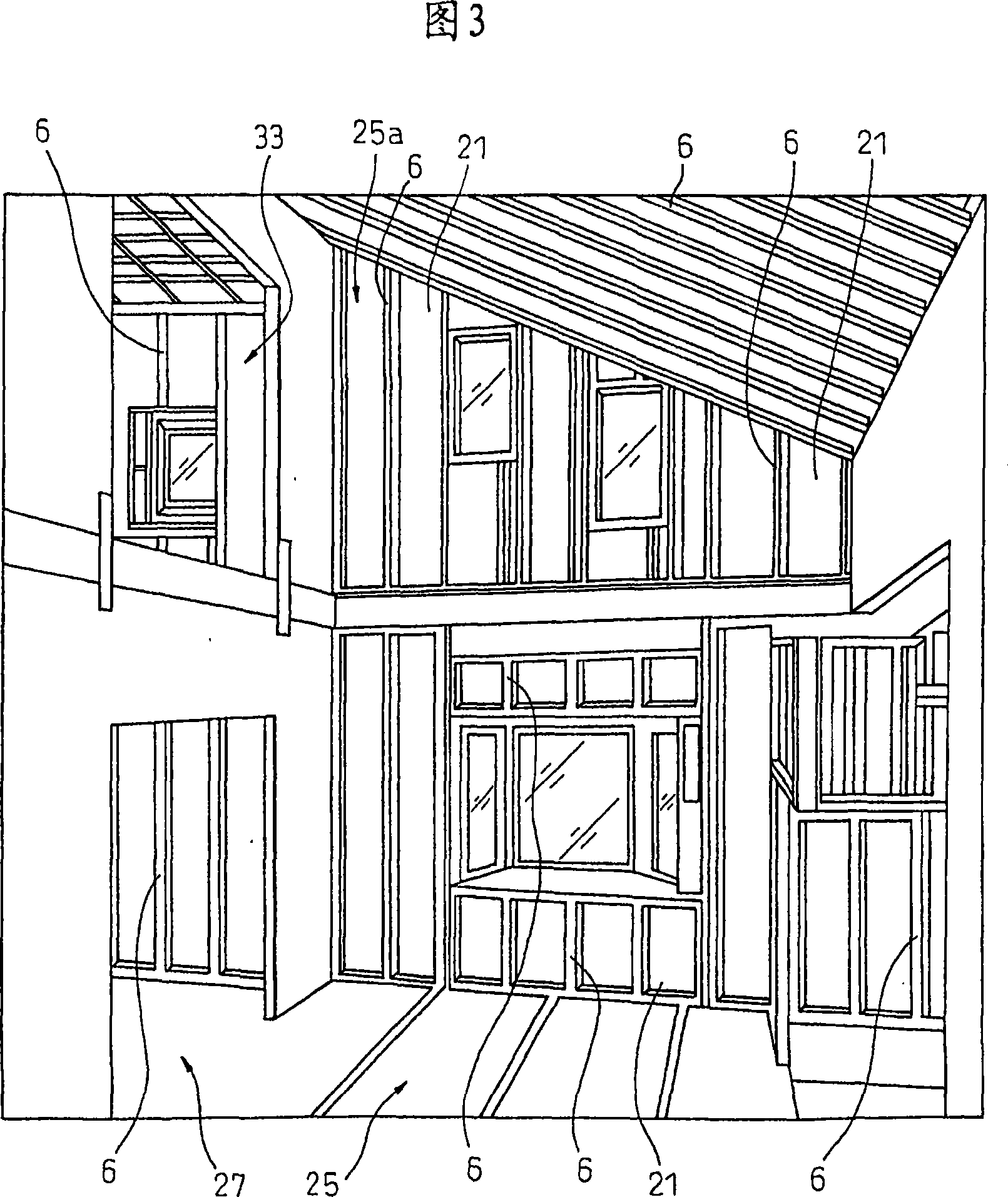

[0036] Embodiments of the present invention will be described below with reference to the drawings.

[0037] In residential buildings, the main body of the structure, such as walls, floors, and roofs, generally adopts a heat-insulating structure that uses heat-insulating materials in the middle layer so that the indoor temperature can be kept as much as possible without being affected by the temperature of the outside air. The heat insulation structure includes an interior heat insulation structure and an exterior heat insulation structure, but the interior heat insulation structure is mostly used in existing building structures. However, when a heat insulating structure is formed, a temperature difference occurs on both sides of the heat insulating layer, and dew condensation occurs. In this case, if the interior insulation structure is adopted, since the insulation layer is located inside the structure main body, and the interior wall members constituting the room are direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com