Dome type dust removing coke quenching machine

A coke quenching tower and coke quenching technology, which is applied in coke ovens, coke cooling, petroleum industry, etc., can solve problems such as the impact of the surrounding environment, and achieve the effects of good dust removal effect, reduced dust content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

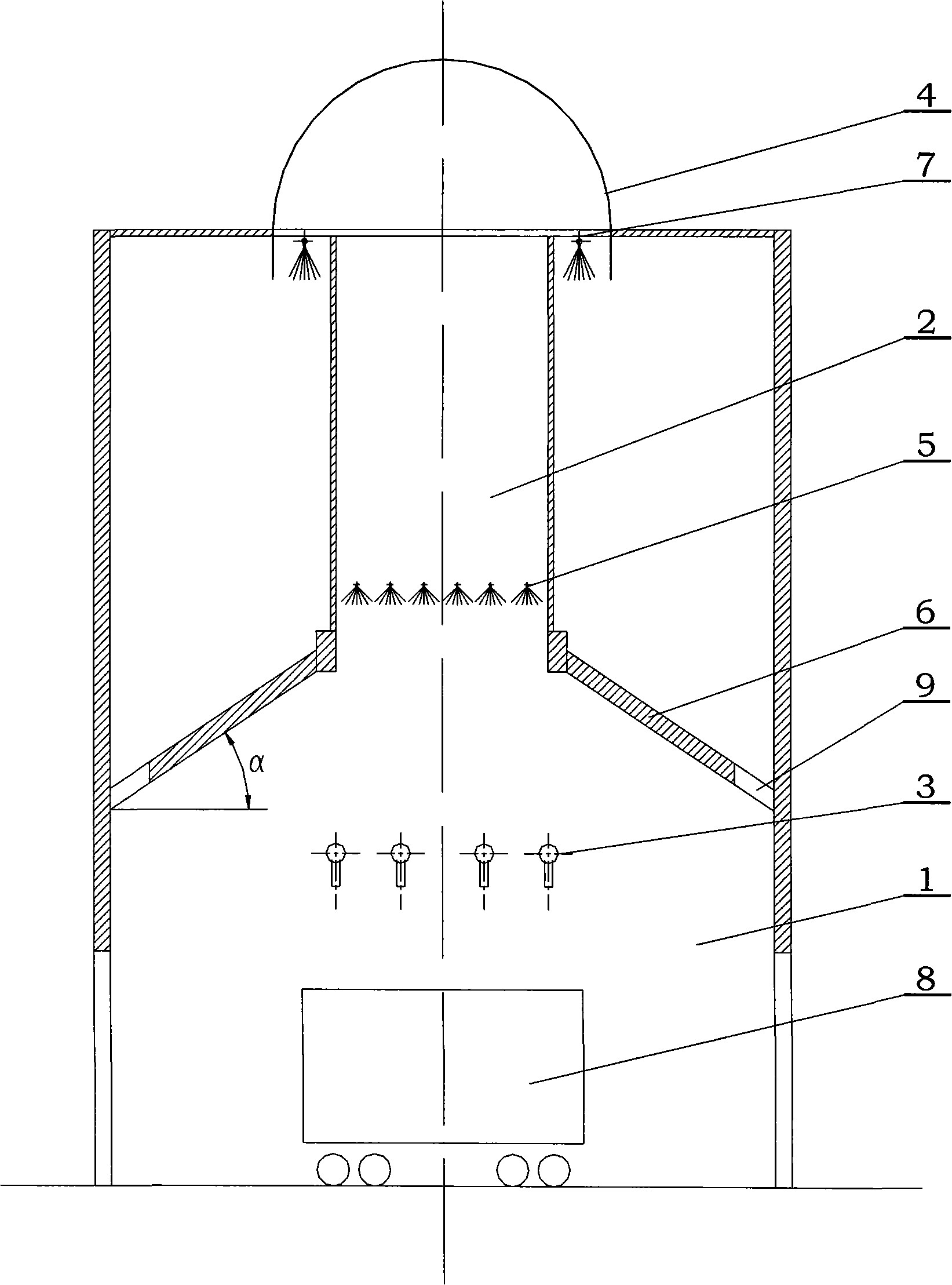

[0011] The dome-type dedusting and coke quenching tower of the present invention is realized in this way. The following is a specific description in conjunction with the accompanying drawings. A dome-type dedusting and coke quenching tower is composed of two parts: a coke quenching section 1 at the bottom and a dust removal section 2 at the top. be rectangular or square. A coke quenching injection pipe 3 is arranged in the coke quenching section 1, and the dedusting section 2 is divided into three compartments, the lower parts of the compartments on both sides are respectively sealed with sloping plates 6, and the lower end of the sloping plate 2 is provided with a sewage hole 9, and the sloping plate 6 is clamped with the horizontal plane. The angle α is 10-75°. A set of washing and cooling device 5 composed of water pipes and nozzles is set above the coke quenching injection pipe 3 and at the entrance of the middle compartment of the dust removal section 2, and a dome-type d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com