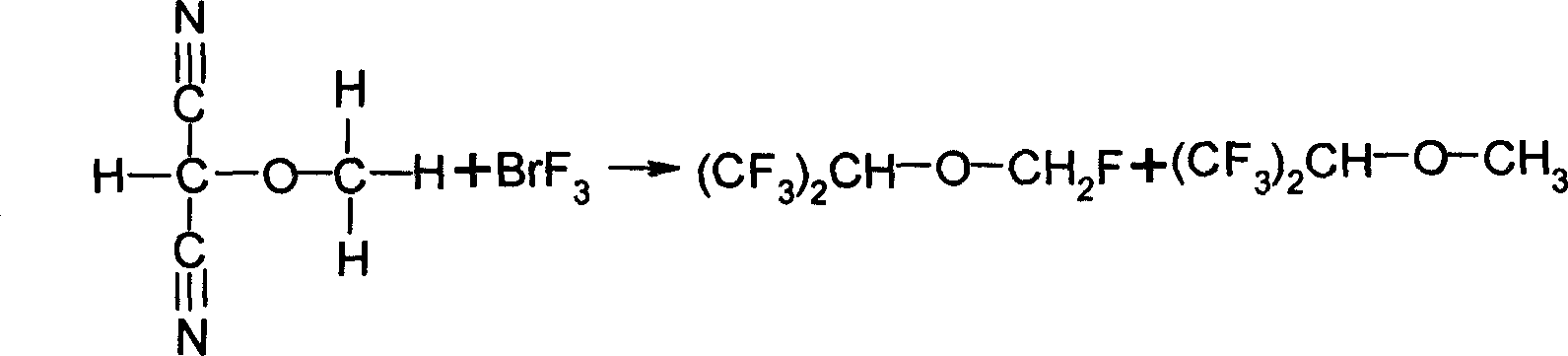

Method of synthesizing fluoromethyl-1,1,1,3,3,3-hexafluoroisopropyl ether

A technology for the synthesis of hexafluoroisopropyl ether, which is applied in chemical instruments and methods, preparation of ether, preparation of organic compounds, etc., can solve the problems of high price and danger, and achieve low price, easy removal, handling and operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]A 50L glass reactor with a lower outlet was used, with a set of mechanical stirring devices, a thermocouple, an internal coil and a refrigeration compressor. Add 3556g (25.86mol) of phosphorus trichloride, lower the system to 0°C and add 4345g (48.28mol) of HFIP while stirring, continue stirring until the HCl gas is exhausted, then add 1,3,5-trioxane 2327g (25.86mol). The temperature will rise to about 8°C, but then it will drop back to 0°C, and the stirring reaction will continue for 8 hours. Then began to slowly add 4L of 6N HCl dropwise. The reaction is an exothermic reaction, so the temperature will rise and be maintained at 45°C. Then add 5L of deionized water and stir until all the solids are dissolved and the system is clearly divided into two layers. The bottom layer is taken out to obtain the product chloromethyl-1,1,1,3,3,3-hexafluoroisopropyl ether.

Embodiment 2

[0028] A 50L glass reactor was used with a mechanical stirring device, a thermocouple and a thermostatic jacket. Dissolve 7031g (32.48mol) of chloromethyl-1,1,1,3,3,3-hexafluoroisopropyl ether in 16L dimethyl sulfoxide and continue stirring, while stirring, add 1364g (32.48mol) of NaF It was fluorinated, then heated to 30°C and reacted for 1h. Add 5 L of deionized water and stir until the solution is clearly divided into two layers, then take out the bottom layer to obtain the product sevoflurane.

Embodiment 3

[0030] A dry 250ml round bottom flask was used with a PTFE stir bar, a thermometer and a freezer. Open the freezer to freeze, make the system temperature drop to 0 ℃, add aluminum trichloride 18.6g (0139mol), HFIP31.2g (0.186mol) in the flask, pass N 2 Bubble for ten minutes to drive away the HCl gas that is not conducive to the reaction in the system. Then add 4.18 g (0.034 mol) of paraformaldehyde, turn off the freezer, let it rise to room temperature freely and start stirring. After reacting for 12 hours, add 50ml of 6N HCl dropwise. After the dropwise addition, add 50ml of deionized water and pour it into a separatory funnel for layering. After taking out the bottom clear liquid, the product chloromethyl-1,1,1 , 3,3,3-Hexafluoroisopropyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com