Heliostat with glass micro-arc curved surface mirror forming process structure

A molding process and curved mirror technology, applied in the field of solar energy utilization, can solve the problems of expensive coating equipment, small curvature of the heliostat, and large focal length of the heliostat, and achieve the benefits of popularization and application, reasonable structural design, and improved molding accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

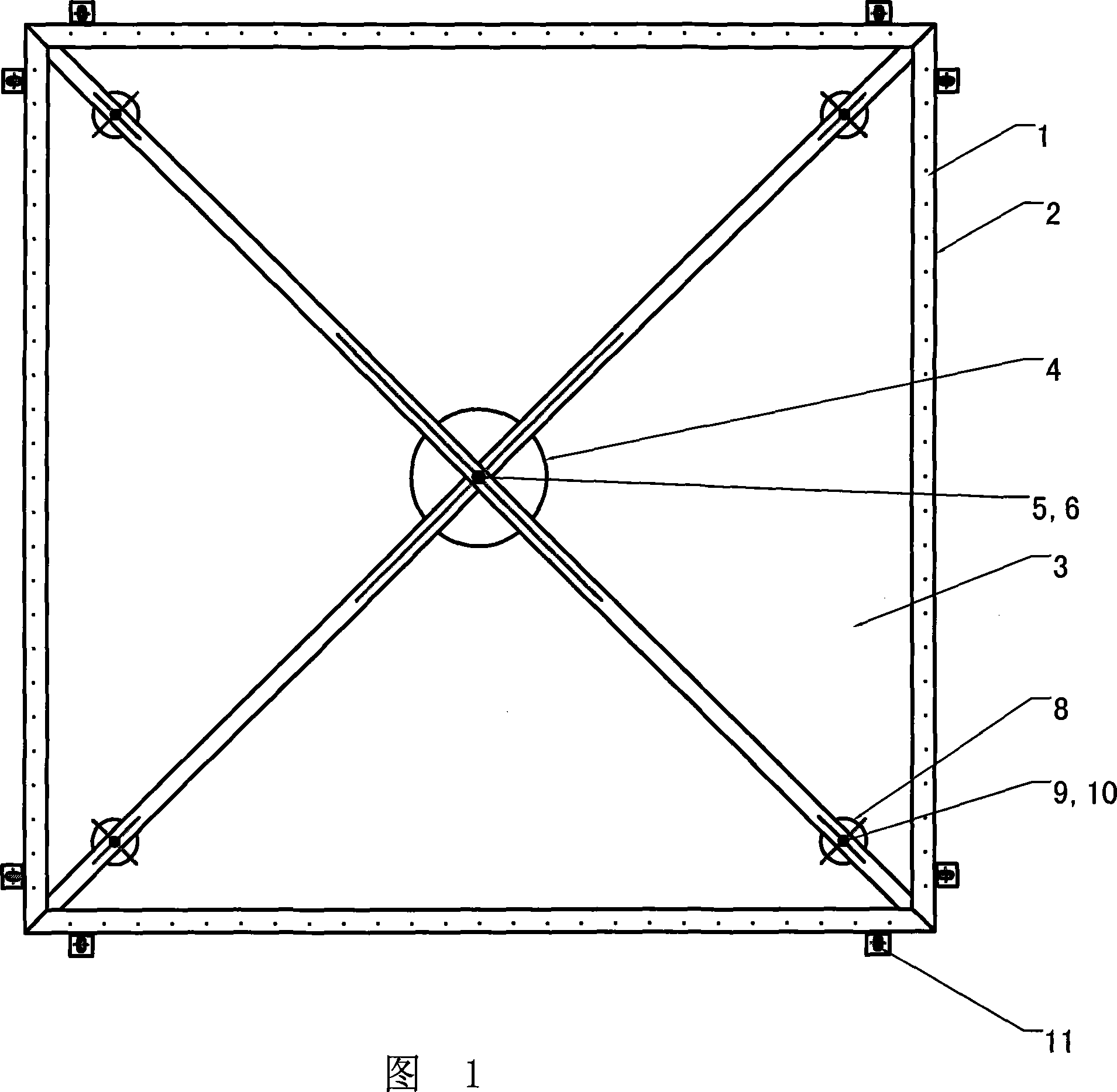

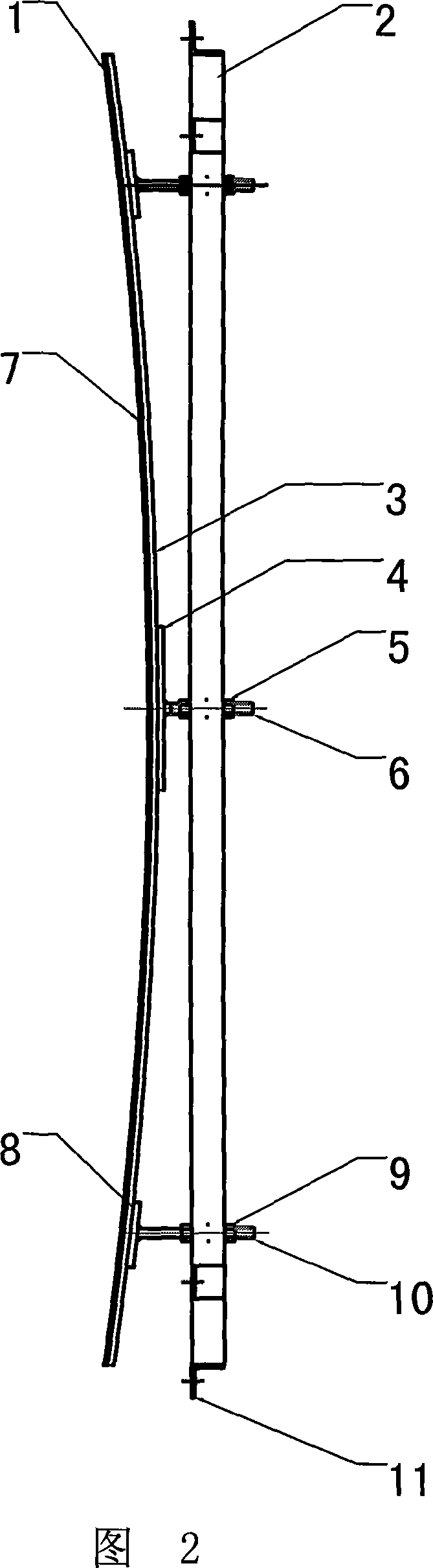

[0020] As shown in Figures 1-8, the glass micro-arc curved mirror forming process structure heliostat in this implementation case is mainly composed of a curved mirror combination adjustment device and a group of rectangular monoliths that are adjacently arranged and attached to the curved mirror combination adjustment device Forming and adjusting device for glass micro-arc curved mirror.

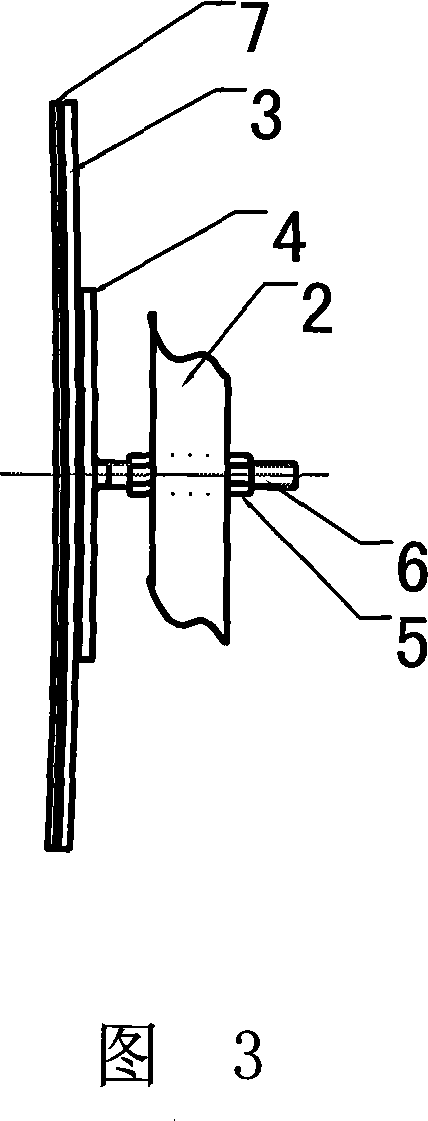

[0021] The single-piece glass micro-arc curved surface mirror forming adjustment device is shown in Figure 2, mainly composed of glass frame 1, glass mirror support frame 2, laminated glass 3, small suction cup 4, main adjustment nut 5, main adjustment bolt 6, flat glass mirror 7, support suction cup 8, micro-adjustment nut 9 and micro-adjustment bolt 10 to form. The glass micro-arc curved mirror is composed of a flat glass mirror 7 and a laminated glass 3 that are bonded to each other. The laminated glass 3 is placed on the back of the flat glass mirror 7, the small suction cup 4 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com