Catalyst used for directly synthesis ethylene with carbon monoxide and hydrogen and its technology

A catalyst and ethylene technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve problems such as high energy consumption, complex processes, and complex reaction products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

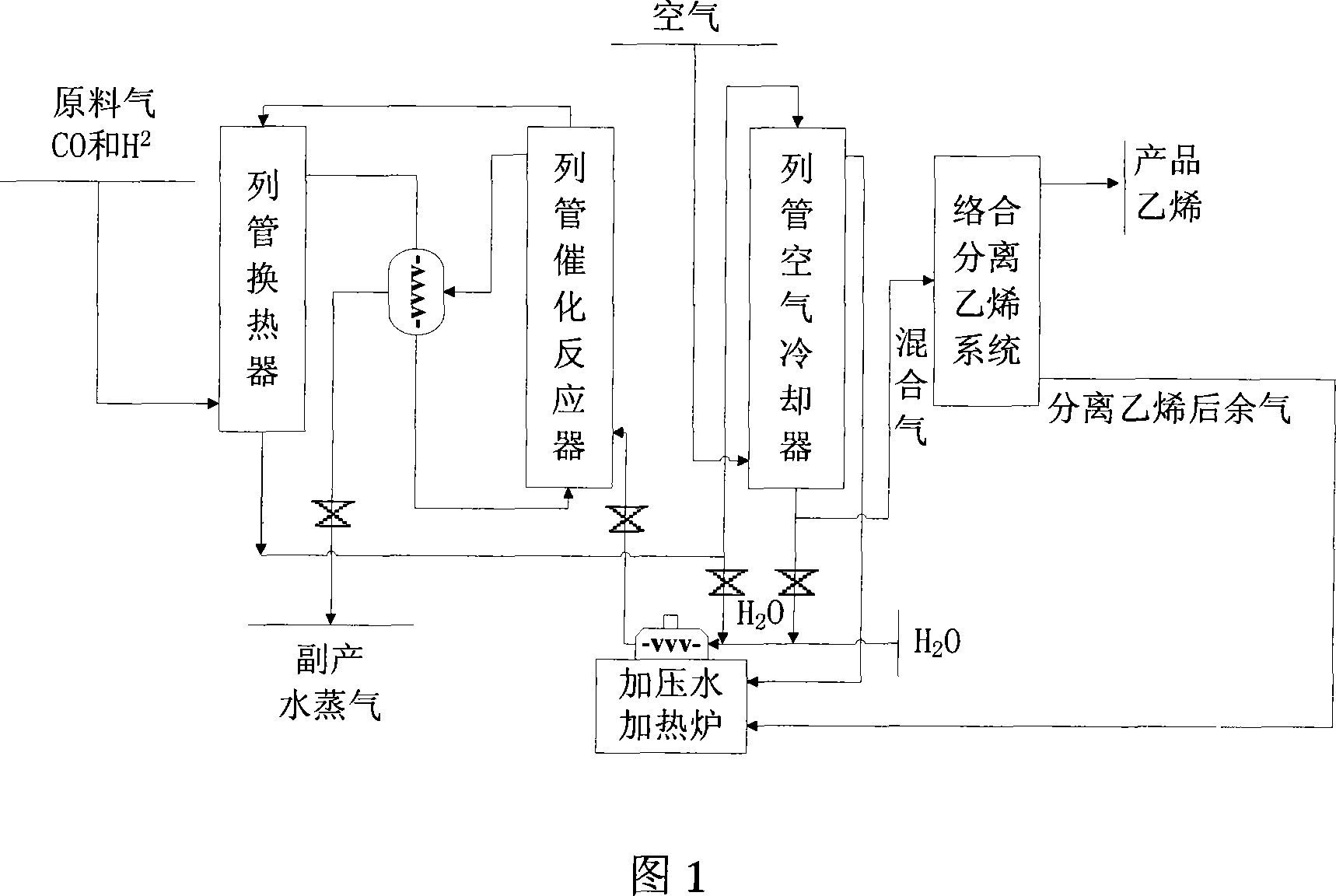

Image

Examples

Embodiment 1

[0014] Embodiment 1, the preparation of Ni-Cu / MgSiO catalyst and its catalytic reaction process

[0015] A certain amount of activation treatment (φ1nm, average pore diameter 10nm, specific surface area 240m 2 / g) Industrial carrier SiO 2 , impregnated into SiO with 2 Carrier pore volume equivalent, Mg 2+ The concentration corresponds to MgCl with a surface Mg / Si atomic ratio of 1:6 2 Aqueous solution, after surface reaction, soaking in ammonia water, filtering and washing, drying and calcination, Mg 2+ A surface composite oxide MgSiO carrier with a semi-monolayer distribution; a certain amount of MgSiO surface composite oxide carrier prepared according to the above process, impregnated into the pore volume equivalent, Ni 2+ and Cu 2+ The concentration of the mixed nitrate aqueous solution with the atomic ratio of Ni / Cu 2:1 and the atomic ratio of Mg / Ni-Cu 4:1 was dried, calcined, and reduced to obtain φ1.2nm Ni-Cu particles uniformly distributed on the surface of MgSiO. ...

Embodiment 2

[0017] Embodiment 2, the preparation of Ni-Cu / TiSiO catalyst and its catalytic reaction process

[0018] A certain amount of activation treatment (φ1nm, average pore diameter 10nm, specific surface area 240m 2 / g) Industrial carrier SiO 2 , impregnated into SiO with 2 The carrier pore volume is equivalent, Ti 4+ Titanium isopropoxide chloride-acetone solution whose concentration conforms to the surface Ti / Si atomic ratio of 1:6, after surface reaction, soaking in ammonia water, filtering and washing, drying and calcination, Ti 4+ A surface composite oxide TiSiO carrier with a semi-monolayer distribution; a certain amount of TiSiO surface composite oxide carrier prepared according to the above process, impregnated into the TiSiO surface composite oxide carrier equivalent to its pore volume, Ni 2+ and Cu 2+ The concentration of Ni / Cu atomic ratio 2: 1 and Ti / Ni-Cu atomic ratio 4: 1 mixed nitrate aqueous solution, through drying, calcination, reduction process to prepare φ1.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com