Optical recording medium, recording and reproducing method thereof, and optical recording and reproducing apparatus

An optical recording medium and recording layer technology, which can be applied to recording/reproducing by optical methods, optical recording carriers, temperature recording methods, etc., can solve problems such as insufficient performance, and achieve reduced crosstalk, good recording signal performance, and stable recording. and reproduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

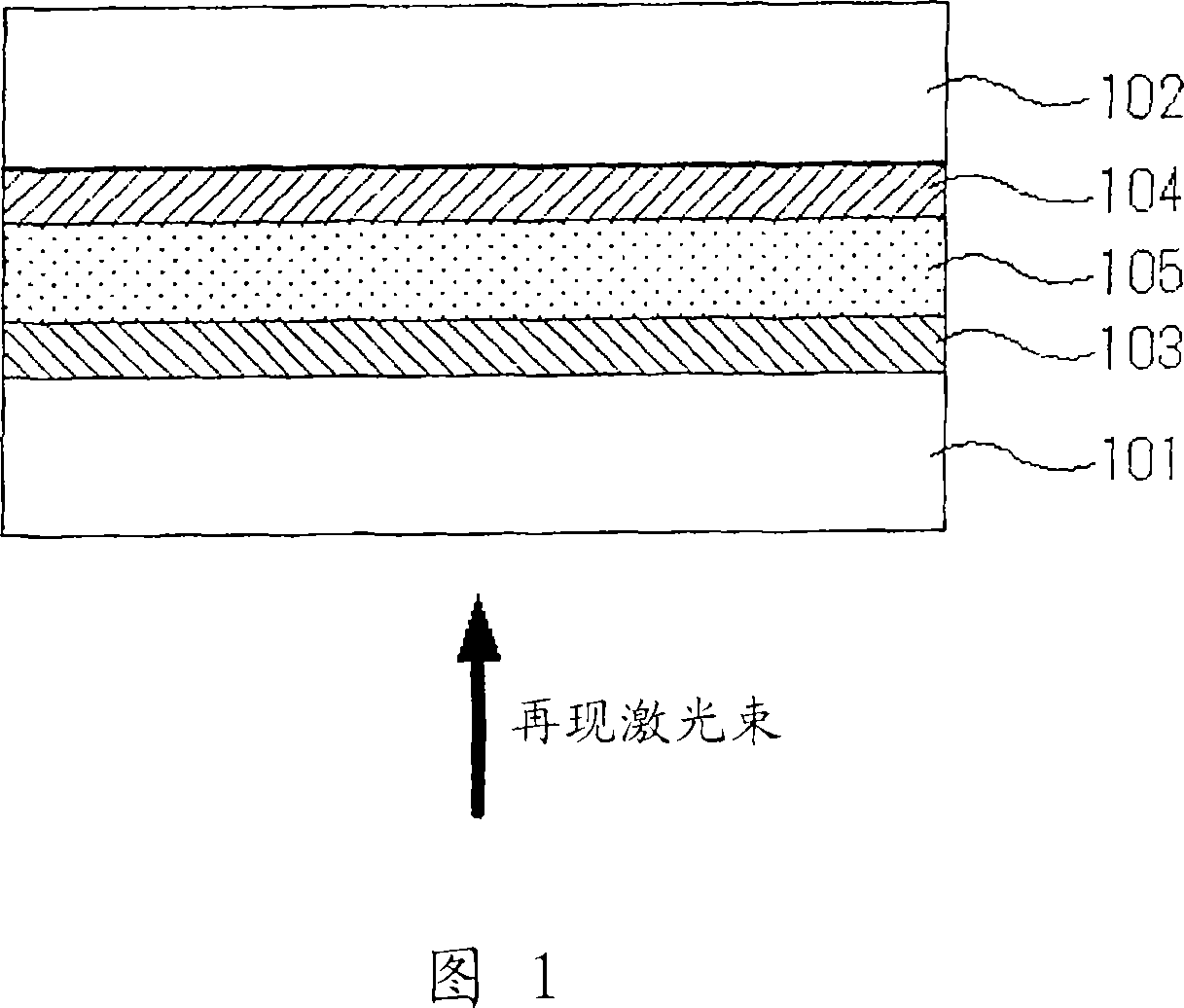

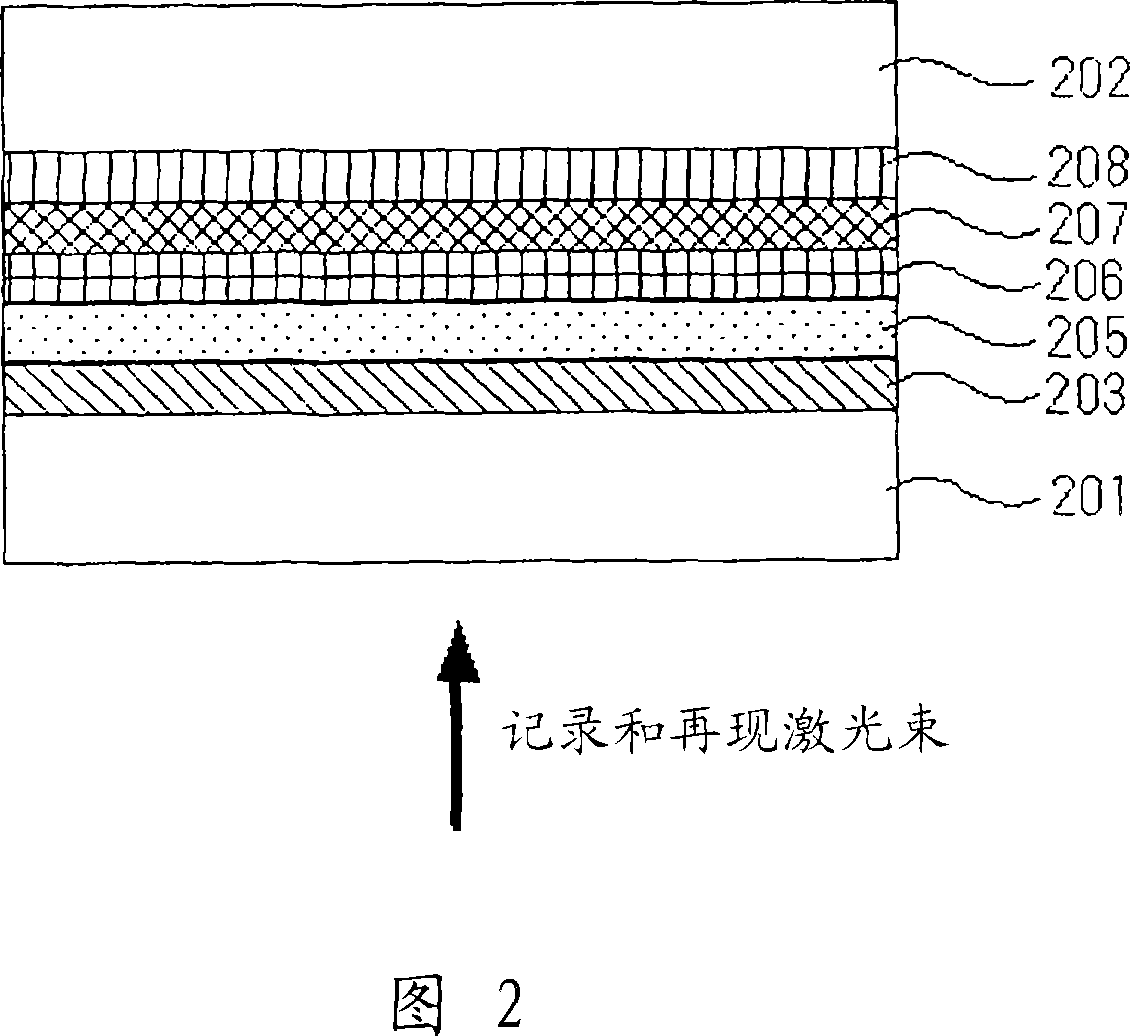

[0166] -Preparation of Optical Recording Medium-

[0167] A concavo-convex shape made of polycarbonate resin having a diameter of 120 mm and a thickness of 0.57 mm on which a guide groove of a depth of 32 nm (320 Å) and a width of 0.25 μm (at the bottom of the groove) was formed A patterned second substrate, wherein the pattern has a track pitch of 0.74 μm. On the second substrate, a second reflective layer containing AgIn (the mixing ratio of Ag to In is 99.5 to 0.5 in atoms) was formed to have a thickness of 150 nm (1500 Å) by a sputtering method using Ar as a sputtering gas.

[0168] Next, on the second reflective layer, a layer having a thickness of 80 nm (800 A), the squarylium dye compound A is represented by formula (3), and has the substituents shown in Table 1.

[0169] Next, on the second recording layer, a protective layer containing ZnS-SiC (the molar ratio of ZnS:SiC is 8:2) was formed to have a thickness of 150 nm (1500 nm) by a sputtering method using Ar as a ...

Embodiment 2 to 6 and comparative example 1 to 3

[0185] -Preparation of Optical Recording Medium-

[0186] In addition to changing the squarylium metal chelate A as the material of the second recording layer to the squarylium metal chelate B to I represented by the formula (3) and containing the substituent shown in Table 1, with the implementation An optical recording medium was prepared in the same manner as in Example. For each of the squarylium metal chelates B to I, the pyrolysis temperature and the pyrolysis temperature range were measured in the same manner as in Example 1. The results are shown in Table 1.

[0187]

[0188] Each optical recording medium was evaluated in the same manner as in Example 1. It was found that reflectance (I14H) was 19%, modulation (I14 / I14H) was 90%, and PI Sum 8 after recording was 20 or less. Therefore, signal performance satisfying the DVD-ROM standard is obtained.

[0189] Also, the amount of crosstalk was evaluated in the same manner as in Example 1. The results are shown in Ta...

Embodiment 7

[0191] -Preparation of Optical Recording Medium-

[0192] Except that the thickness of the second recording layer is changed to 50nm (500 Ȧ) and the thickness of the protective layer containing ZnS-SiC, wherein the molar ratio of ZnS to SiC is 8 to 2 is changed to 180nm (1800 Ȧ). 1 Prepare an optical recording medium in the same manner.

[0193]

[0194] Each optical recording medium was evaluated in the same manner as in Example 1. It was found that: reflectivity (I14H) of 18%, modulation (I14 / I14H) of 65%, and PI Sum 8 of 20 or less after recording; signal performance satisfying the DVD-ROM standard was obtained.

[0195] Also, the amount of crosstalk was evaluated in the same manner as in Example 1. The results are shown in Table 2 and Figure 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com