Method for manufacturing electrode, apparatus for manufacturing electrode, and method for manufacturing secondary cell

A manufacturing method and secondary battery technology, applied in electrode manufacturing, secondary batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of uneven drying of the electrode layer, solute bias flow, inability to obtain a uniform electrode layer, etc., and achieve difficult cracking. And the effect of incision, heat release uniformity, no local deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0103] Preparation of spinel-type LiMn as positive electrode active material 2 o 4 (average particle diameter: 0.6 μm), carbon black (2 parts by mass) as a conductive material, and a surfactant (5 parts by mass) for stabilizing the dispersion of solid components, to which N-methylpyrrolidone (75 parts by mass). This was stirred well to prepare a composition for positive electrode layer formation (hereinafter referred to as "composition 1"). The composition has a viscosity of approximately 10 cP.

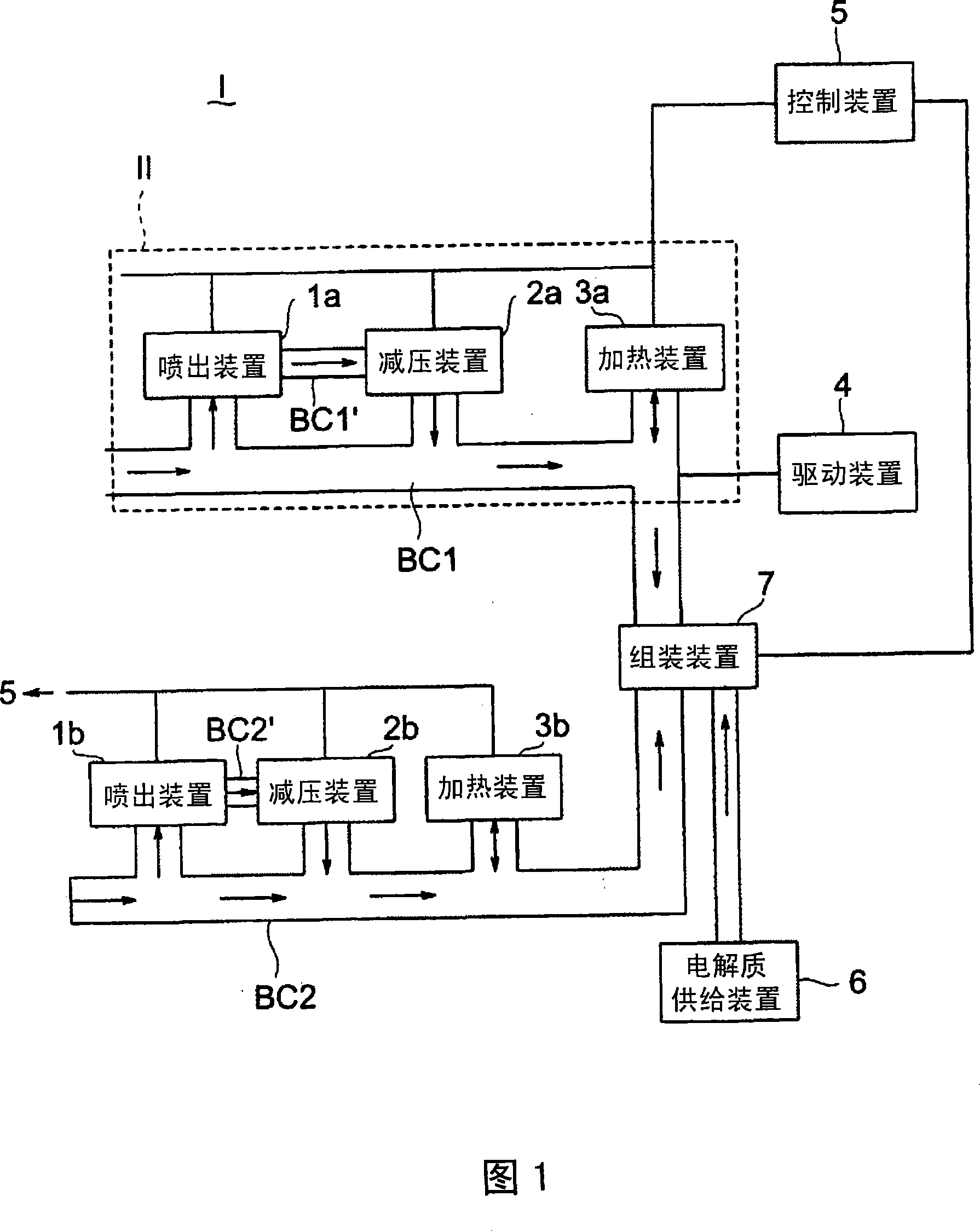

[0104] According to the electrode production line II shown in FIG. 1 , a positive electrode layer was produced using the composition as follows.

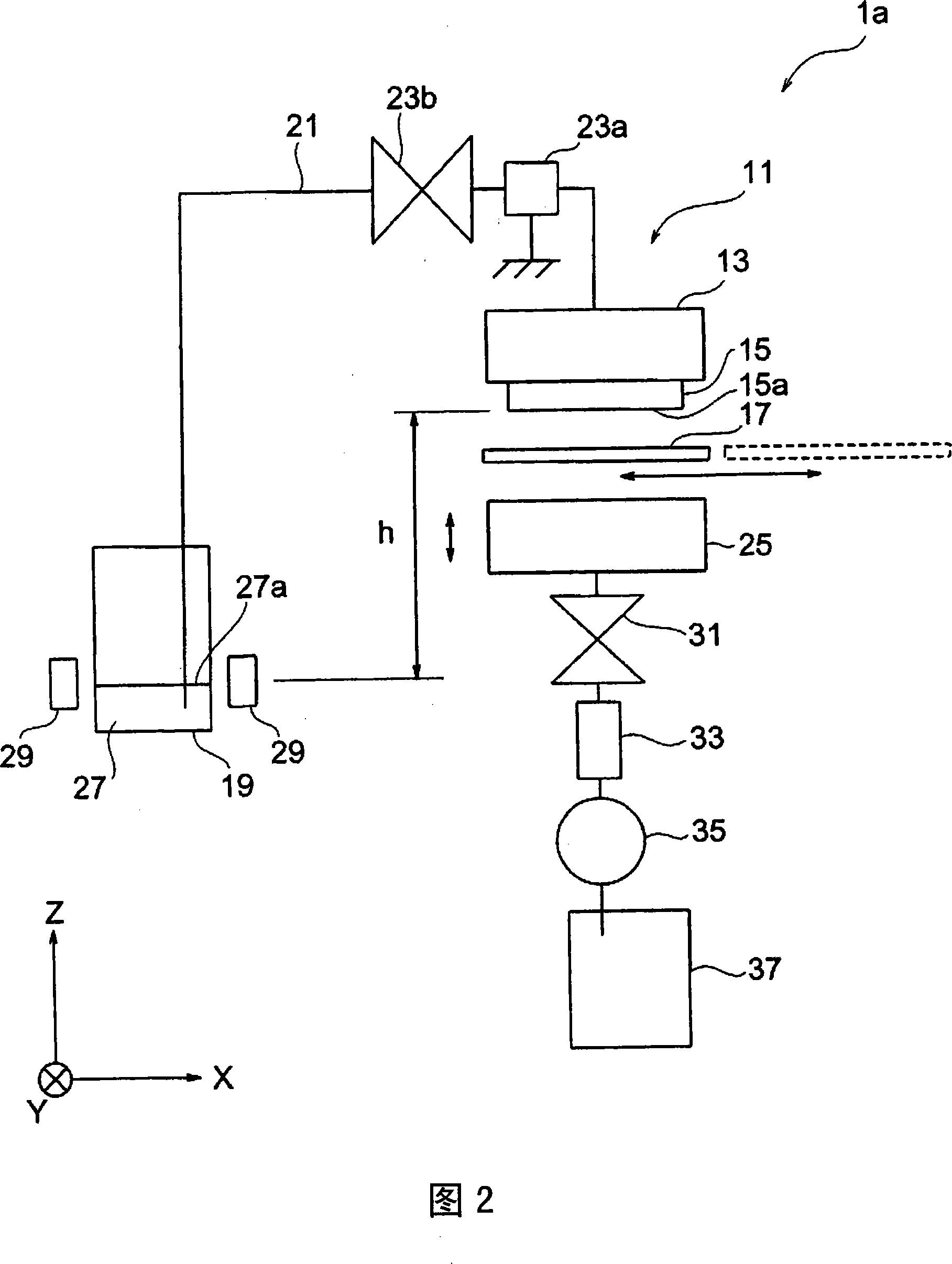

[0105] The composition 1 was introduced into the droplet discharge device 1a, and the composition was discharged onto an aluminum foil having a thickness of 20 μm as a current collector to form a coating film of the composition 1.

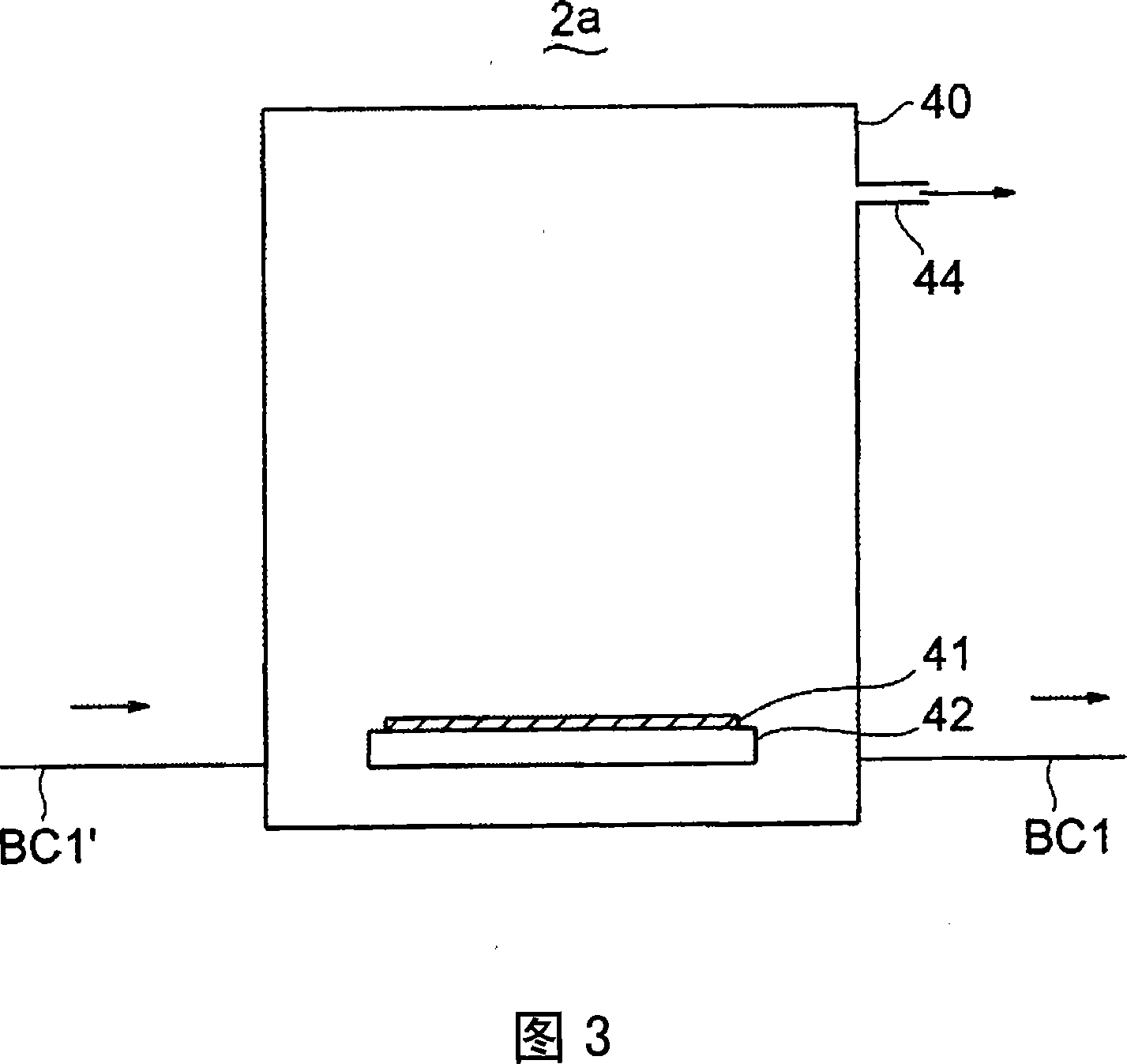

[0106] Within one minute after the coating film is formed, the current collector on which the coating fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com