Horizontal radiation type electrolysis method and device

A technology of electrolysis device and electrolysis method, which is applied in electrolysis process, electrolysis components, chemical instruments and methods, etc., can solve the problems of breeding bacteria, inability to adjust, and increase cost, so as to reduce the generation of turbulent flow, facilitate diversion, and stabilize water flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

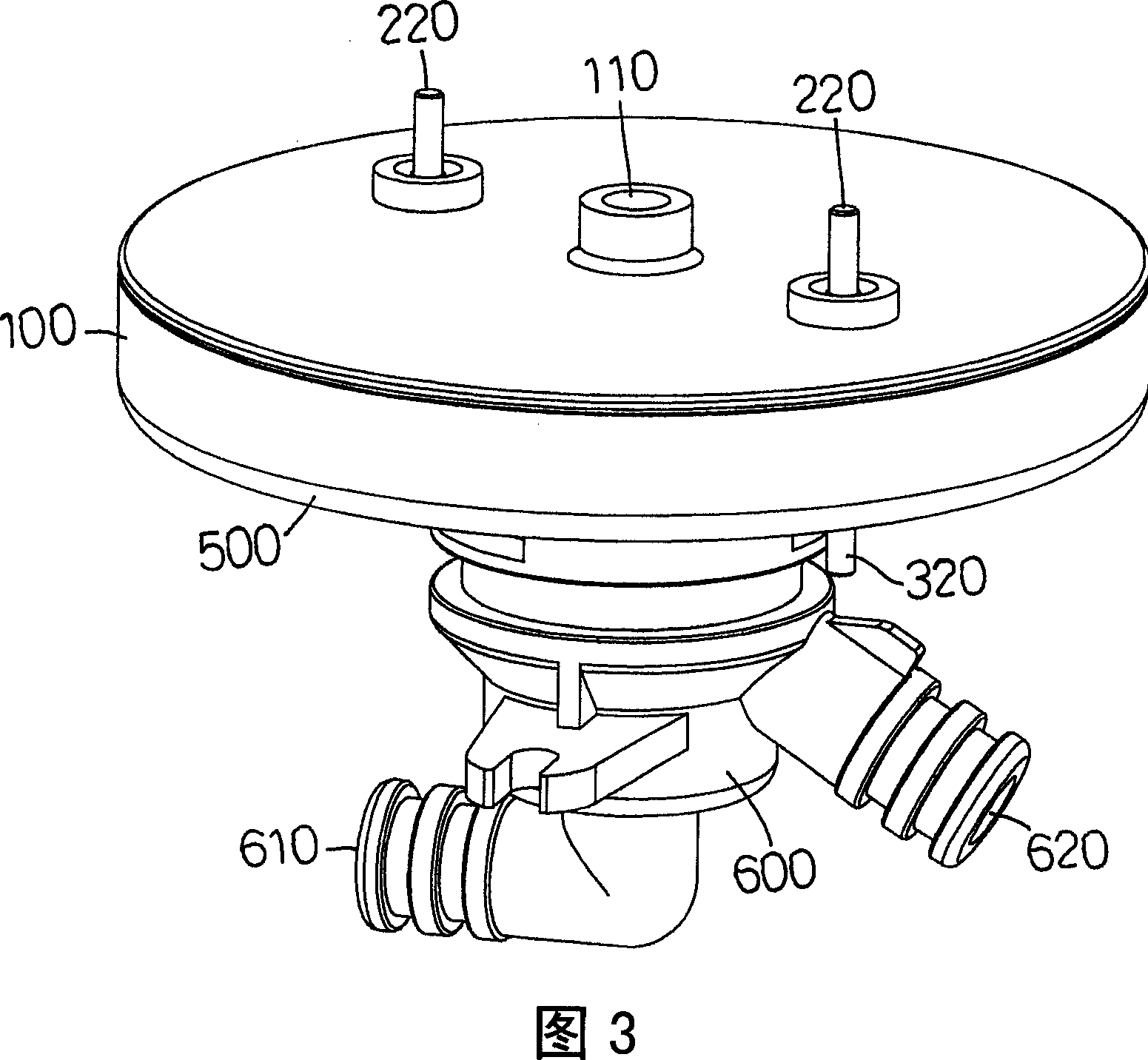

[0189] Embodiment 1, please refer to FIG. 3 and FIG. 4 , which are three-dimensional assembly and three-dimensional disassembly diagrams of Embodiment 1 of the present invention. And as shown in FIG. 5 , which is a cross-sectional schematic diagram of Embodiment 1 of the present invention. The electrolysis device is mainly composed of a cover body 100, an anode electrode plate 200, a cathode electrode plate 300, a diverter plate 400, a seat body 500, a water joint 600, and a plurality of water-stop gaskets Q10, Q20, and Q30; wherein:

[0190] The cover 100 is disc-shaped, the center of the cover 100 is provided with a water inlet 110, the inner surface of the cover 100 can accommodate the anode electrode plate 200, and the outer surface of the cover 100 is provided with two through holes 120 for the anode The two positive conductive parts 220 of the electrode plate 200 pass through, and the inner wall of the cover 100 is provided with an internal thread 130 for locking the sea...

Embodiment 2

[0197] Embodiment 2, the horizontal radiant electrolysis device provided by the present invention, in addition to being able to be designed as embodiment 1 enters water from one side of the cover body 100, and then discharges water from the two sides below the water joint 600, it can also be designed to flow from the water The water enters from the lower part of the joint 600, and then the water comes out from the cover body 100 and the water joint 600 respectively. Please refer to FIG. 8, which is a three-dimensional exploded view of the second embodiment of the present invention. And as shown in FIG. 9 , which is a cross-sectional schematic diagram of Embodiment 2 of the present invention. The electrolysis device is mainly composed of a cover body 100', an anode electrode plate 200', a cathode electrode plate 300', a diverter plate 400', a seat body 500', a water connector 600', an annular diverter device 700' and a plurality of water-stop gaskets. Composed of Q10', Q20', Q3...

Embodiment 3

[0206] Embodiment 3, the horizontal radiant electrolysis device provided by the present invention can be designed to enter water from one side of the cover body 100 in Embodiment 1, and then discharge water from the two sides below the water joint 600, which is similar to Embodiment 2 from the water joint 600 In addition to the form of entering water from the lower side and then exiting water from the cover body 100' and the water joint 600', it can also be designed to enter water from the water joint 50 and then exit the water from the center of the water joint 50 and the other side respectively. For the form, please refer to Fig. 12 and Fig. 13, which are the three-dimensional combination cut-away schematic diagram and the three-dimensional exploded schematic diagram of the third embodiment of the present invention. As shown in FIG. 14 , it is a cross-sectional schematic diagram of Embodiment 3 of the present invention. And as shown in FIG. 15 , which is a partially enlarged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com