Microwave method for treating ballast water on ship

A technology of microwave treatment and ballast water, applied in the fields of sterilization/microdynamic water/sewage treatment, water treatment device, water/sewage treatment, etc. The effect of simple operation, low cost, and easy large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments and examples of the present invention are described in detail below.

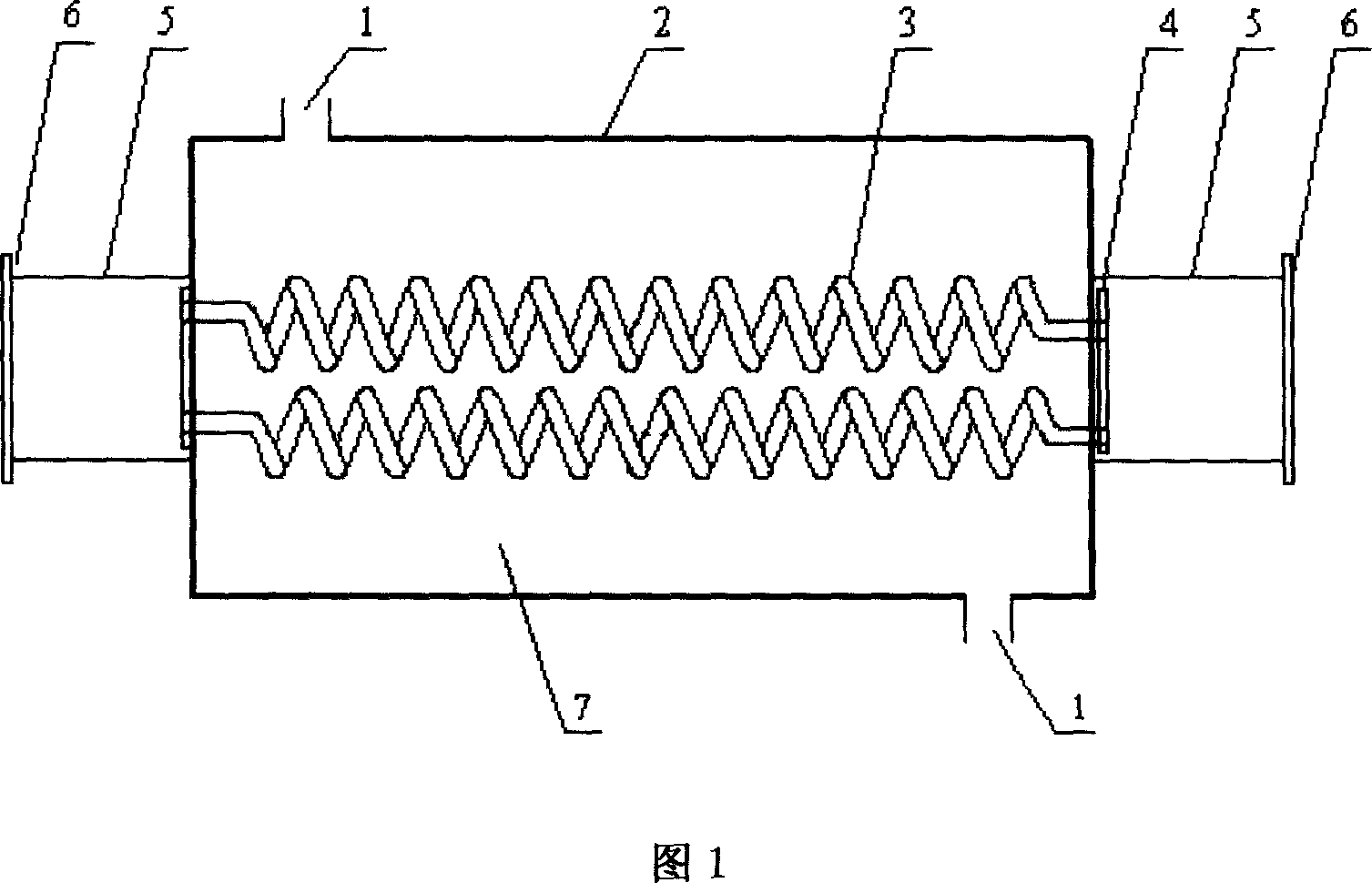

[0016] The onboard microwave treatment device for ballast water is directly embedded in the existing ballast water loading system pipeline on the ship, and the ballast water treatment device is connected to the two ends of the existing ballast water loading system pipeline through the interface 6. Connected, the microwave enters the reaction chamber 7 through the microwave inlet 1. When the ship is loaded with ballast water, the ballast water enters the reaction chamber 7 through the ballast water inlet and outlet pipeline 5, and is divided into the ballast water treatment in the microwave field. In the pipeline 3, the microwave-treated ballast water finally enters the ballast tank through the outlet pipeline 5, and quickly kills the phytoplankton, zooplankton, bacteria and spores in the ballast water. The device for microwave treatment of ballast water includes microwave inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com