Dried type outside and inside dual circulation fluidized bed desulfurizing device and desulfurizing method thereof

A double-circulation, fluidized bed technology, applied in the field of flue gas purification, can solve the problems of complex system investment and increased operating costs, reduce the adjustment range of working parameters of the device, and blockage of the slurry pipeline, so as to improve the desulfurization effect and occupy The effect of small area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

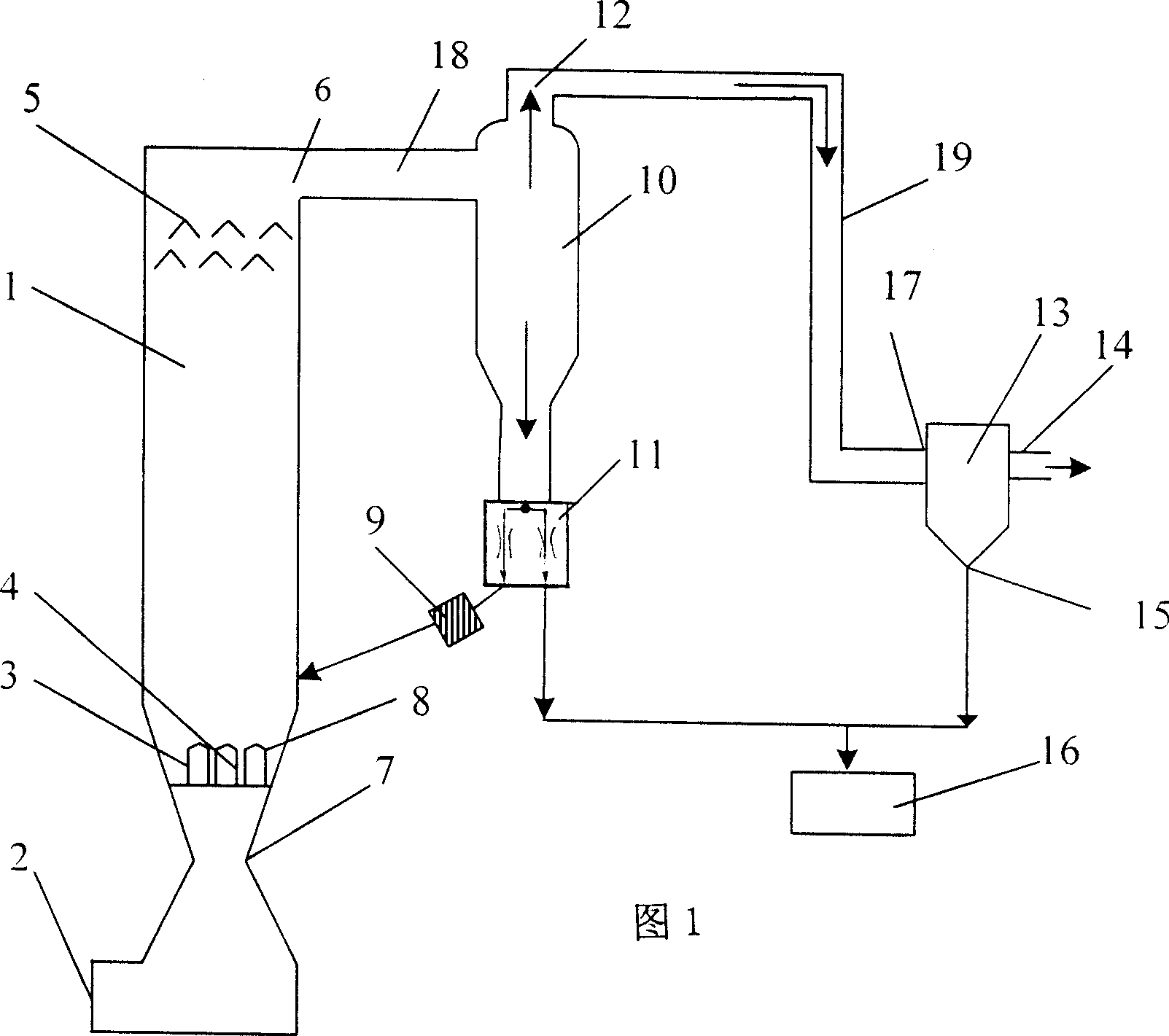

[0044] Make a device of the present invention with reference to accompanying drawing 1, this device comprises internal circulating fluidized bed reaction tower 1, and this tower is cylindrical, height and diameter ratio 2-50, and mechanical valve 6 can also adopt screw feeder; Dust removal The device 13 can be a bag filter or an electrostatic precipitator. For example, SWB type, GP type electrostatic precipitator, or LCM type pulse bag type dust collector, LFSF reverse blowing bag type dust collector, etc. can be selected according to the requirements of flue gas properties, flow rate and dust removal effect. There is a flue gas inlet 2 at the bottom 1 of the circulating fluidized bed reaction tower, and a venturi section 7 of the reaction tower is set above the flue gas inlet 2, where a desulfurizing agent nozzle 3 (or replaced by a screw feeder), water spray nozzle 4 and air nozzle 8, and they are respectively communicated with desulfurization agent supply source, water pipe...

Embodiment 2

[0048] The device in this embodiment application embodiment 1 has a flow rate of 50,000 m 3 / h, SO 2 The concentration is 2000mg / M 3 flue gas treatment.

[0049] First press the SO of the flue gas 2 The concentration is 2000mg / M 3 Calculate the amount of powdered desulfurization agent added, according to the amount of powdered desulfurizer added and SO in the flue gas 2 If the Ca / S molar ratio reaches 1.3, powdery desulfurizers such as lime, carbide slag or steel slag need to be sprayed, and the amount of desulfurizer added is 113kg / h. By adjusting the amount of water spray and air, the flue gas temperature in the reaction tower is kept at about 80°C, and the flow rate of water spray and air is 7m / s; through this process, a desulfurization rate of 90% can be obtained, so that SO in the flue gas 2 Concentration reduced to 200mg / M 3 .

[0050] 1) Make the concentration 2000mg / M 3 Contains SO 2 The flue gas enters the internal circulating fluidized bed reaction tower 1 t...

Embodiment 3

[0054] The device of present embodiment application embodiment 1 is 2000m to the flow rate 3 / h, SO 2 The concentration is 5000mg / M 3 The flue gas is processed, and concrete steps are also with embodiment 1, different conditions are as follows.

[0055] First press the SO of the flue gas 2 The concentration is 5000mg / M 3 Calculate the amount of powdered desulfurizer added, based on the effective Ca in the powdered desulfurizer and the SO in the flue gas 2 If the Ca / S molar ratio reaches 2.0, it is necessary to spray powdered desulfurizers such as steel slag, fly ash, and magnesium oxide, or to mix lime, carbide slag, steel slag, fly ash, and magnesium oxide. Mix in the following proportions, for example: 80 parts of lime, 5 parts of carbide slag, 5 parts of fly ash, and 10 parts of magnesium oxide; or mix in the following proportions: 80 parts of lime, 5 parts of carbide slag, 5 parts of steel slag, and 5 parts of fly ash and 5 parts of magnesium oxide; the general partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com