Amphibious high efficiency self suction centrifugal pump

An amphibious, centrifugal pump technology, applied in the direction of pumps, components of pumping devices for elastic fluids, driving pumps, etc., can solve the problems of difficult automatic opening or closing, no flow, large volume, etc. Wide, easy to operate, high lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

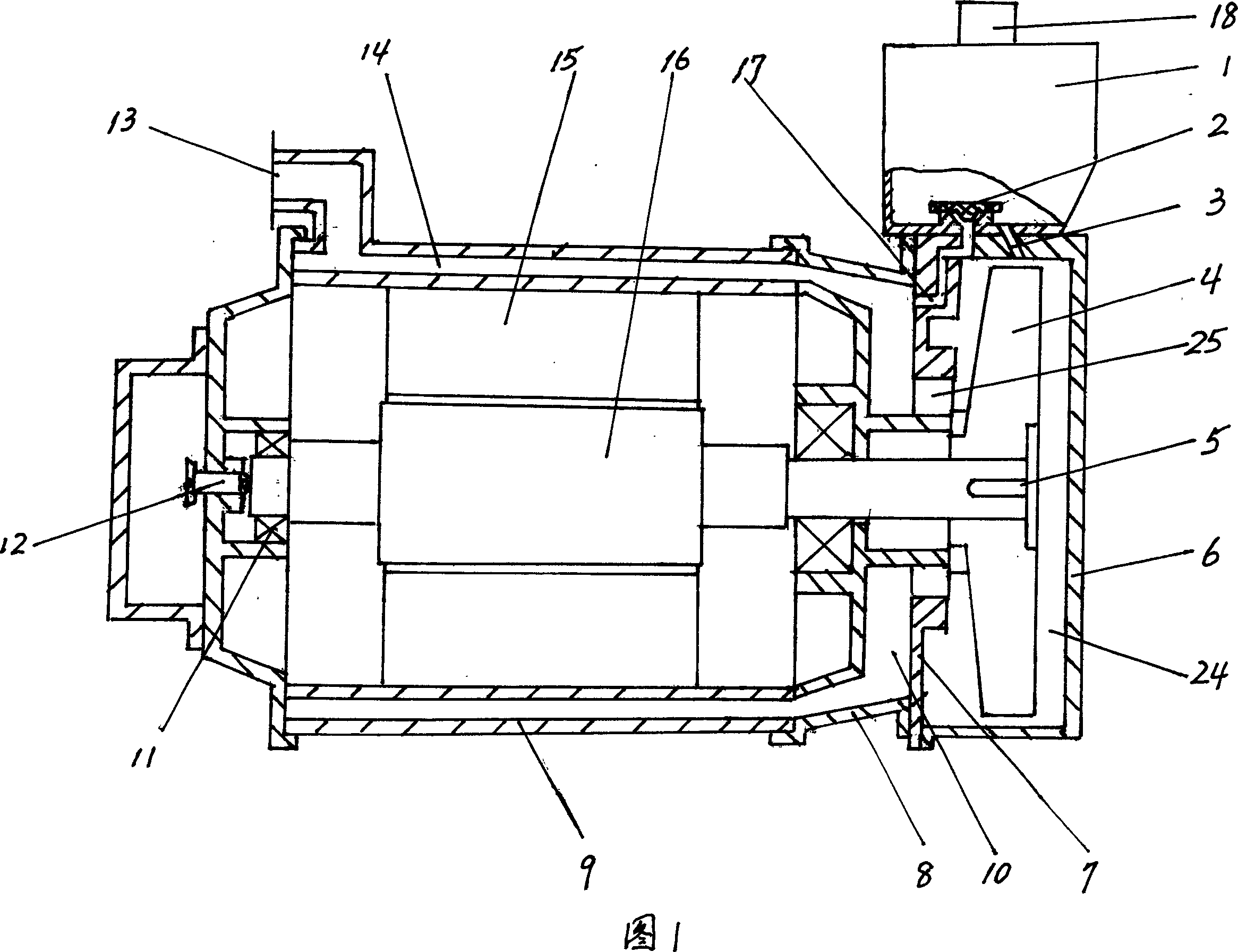

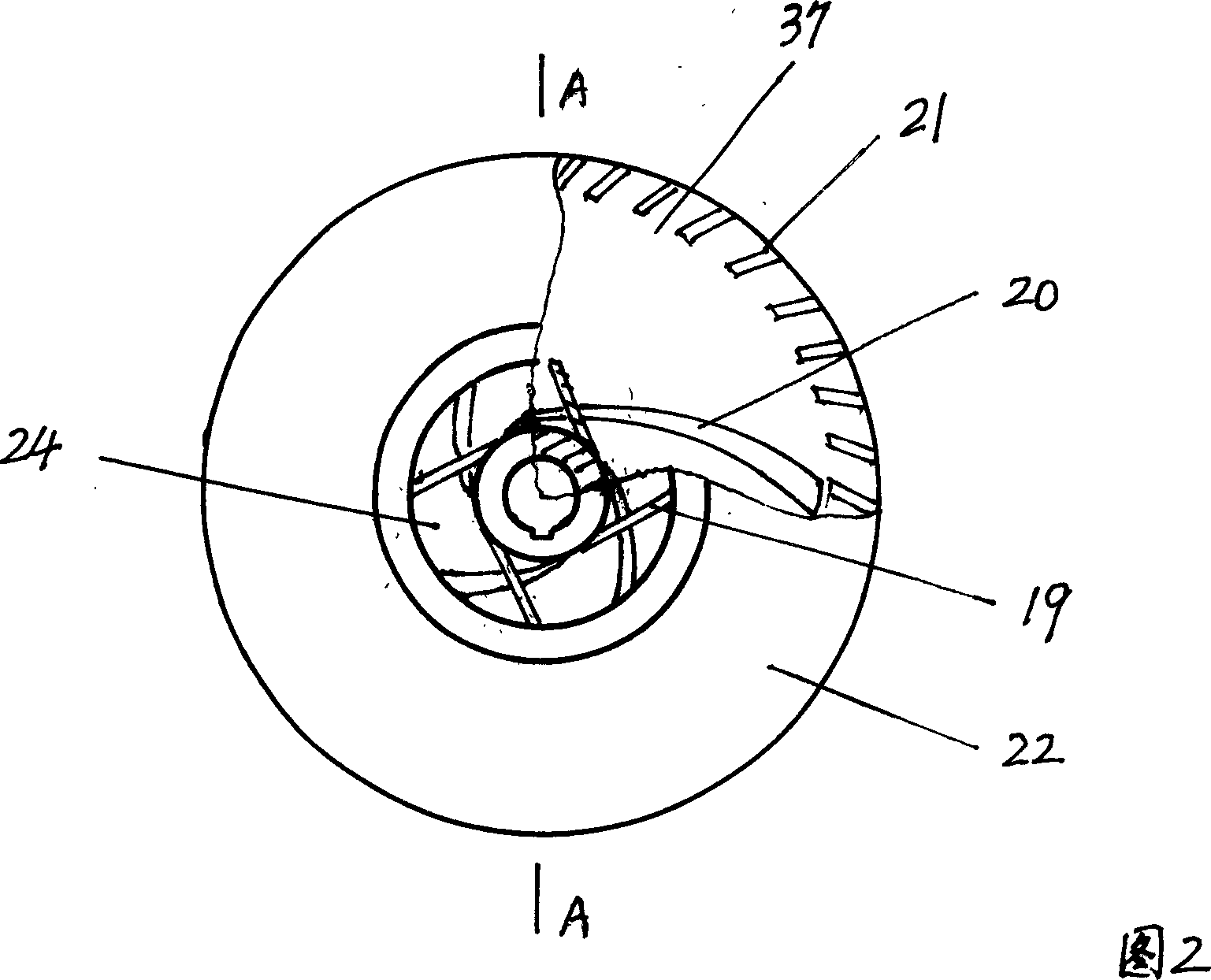

[0014] The structure of the amphibious high-efficiency self-priming centrifugal pump is that the motor stator 15 and the rotor 16 are installed in the motor casing 9, the motor shaft is supported by the bearing 11, and the two ends of the motor shaft are respectively equipped with an impeller gap adjustment device 5 and an axial adjuster 12. The motor casing 9 is a double-layer hollow casing. The hollow layer of the motor casing 9 is a water channel 14. The motor casing 9 has a water inlet pipe 13 and communicates with the water channel 14. The other end of the motor casing 9 is connected to the impeller seat plate 7 through the motor end cover 8. The impeller 4 is contained on the motor shaft, and the impeller 4 is covered in the inner cavity of the impeller cover 6 and the impeller seat plate 7, and the impeller 4 has an impeller water inlet end cavity 23 and an impeller inner cavity 24 that are connected. The impeller 4 is equipped with three-stage blades, the first-stage bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com