Composition of silicon dioxide - metal hud particles, and preparation method

A technology of nanocomposite and silica, which is applied in the preparation of nanocomposite silica-metal core-shell particles, in the field of nanocomposite silica-metal core-shell particles, which can solve the problems such as the degree of change is not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Synthesis of silica-based cores in core-shell particles

[0033] Add 50mL of absolute absolute ethanol and 3.0mL of ammonia (25%) into a 100mL clean beaker. Under stirring conditions, add 0.2mL (0.9mmol) of 99.999% pure ethyl orthosilicate to the solution. (TEOS), the solution becomes milky white turbid after about 15~30mim, continue to stir for 8h. Silica particles with an average particle diameter of 140 nm were obtained. Measure the surface charge and pH value of the solution with a dynamic light scattering instrument.

[0034] By adjusting the concentration of ammonia and the amount of TEOS, spherical silica particles with a particle size of 100-250 nm can be synthesized.

[0035] (2) Ammonification of silica surface

[0036] Take the silica particle suspension obtained in the above experiment for centrifugal separation (1000-2000rpm), discard the supernatant, add 10 mL of ethanol to the precipitate, and ultrasonically disperse for 5 min. Add 400uL of aminopropyltri...

Embodiment 2

[0044] (1) Synthesis of silica-based cores in core-shell particles

[0045] In a 100mL clean beaker, add 50mL of absolute absolute ethanol and 15.0mL of ammonia (5.0%). Under stirring, add 0.2mL (0.9mmol) of 99.999% pure ethyl orthosilicate to the solution. (TEOS), the solution becomes a translucent turbid liquid after about 15-30 minutes, and the stirring is continued for 8h. Silica particles with an average particle diameter of 100 nm were obtained.

[0046] Adjusting the amount of TEOS in Example 1 (1) to 0.4 mL and the amount of other reagents unchanged, after similar reactions, silica particles with an average particle size of 250 nm can be obtained.

[0047] Generally speaking, under the same dosage of other reagents, the lower the concentration of ammonia, the smaller the particle size of the obtained silica particles; the more the amount of TEOS, the larger the particle size of the obtained silica particles.

[0048] (2) Ammonification of silica surface

[0049] Take the s...

Embodiment 3

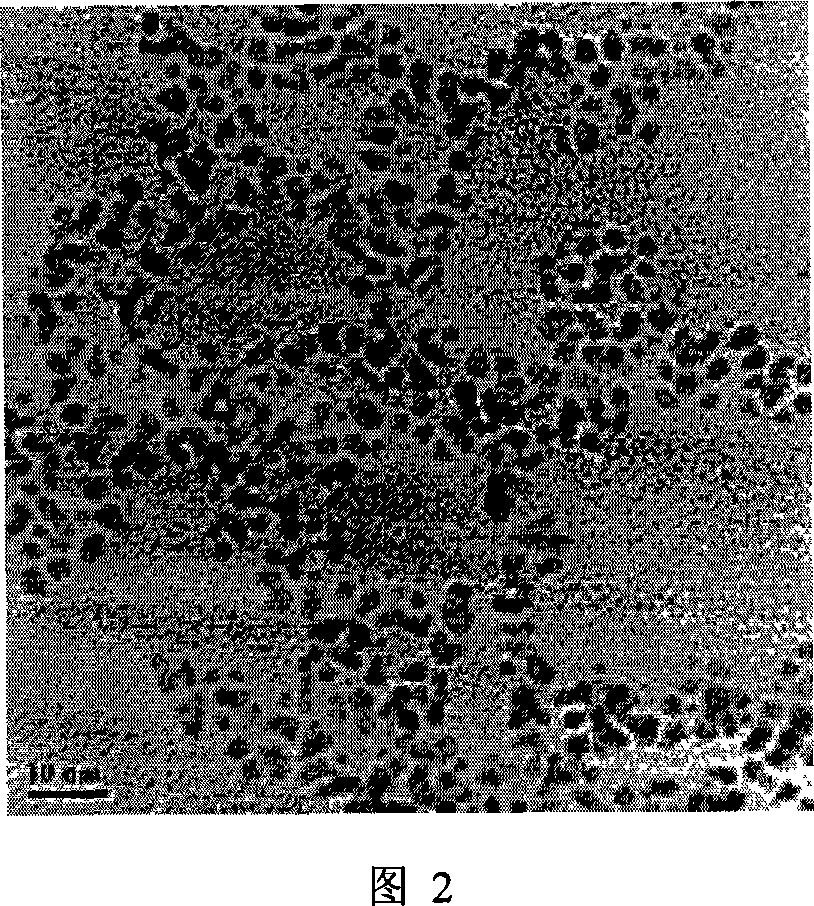

[0055] Take 1mL of the seed gold solution in the above example 1(4) and mix with 30mL of PCG solution. After stirring vigorously for 10 minutes, quickly add 3mL of formaldehyde solution (1%), continue stirring for 0.5h, and centrifuge at 3000~5000rpm. Separate and remove the nano metal particles that are not adsorbed on the surface of the seed gold, and repeat this operation at least 5 times. The resultant precipitate was re-dispersed in 5 mL of water by ultrasound. The concentration of nanoparticles in the solution was about 4×10 11 Pieces / mL. The particle size was measured by the transmission electric environment and the UV absorption was measured by the ultraviolet spectrometer, and the surface charge and the pH value of the solution, as well as the particle size and particle size distribution were measured by a dynamic light scattering instrument. The surface of the nano-silica is continuously wrapped with a layer of gold, and the thickness of the gold layer is about 5 nm. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com