Coke pushing method and coke pusher machine

A technology for ejecting device and coke, which is applied in the direction of unloading device, furnace safety device, coke oven, etc., and can solve problems such as increased friction between lump coke and the side wall of the carbonization chamber, reduced load that cannot be ejected, and long time , to achieve the effects of easy management, suppression of damage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] In order to study the effect of vibration, a vibration experiment was carried out. exist Figure 4 The small simulated coke oven 30 of 1m x 0.8m x 0.4m shown in the figure puts the lump coke 11 produced by dry distillation in advance in a small coke oven with the same shape and size as the simulated coke oven, and pushes it out by exerting force on the side wall 31 , While applying vibration (frequency 1-110Hz, acceleration level 0.3-12G, sine wave) from the end face with a test rod, it is pushed out at a certain speed, and the required force is measured. It is possible to vibrate 1 / 2 of the test rod 32 and vibrate with the vibrator 33 from the back. Figure 5 to Figure 8 An example showing the transition of pushing force. The horizontal axis represents time (since the speed is constant, it represents position), and the vertical axis represents the pushing force of the test rod. Wherein, for the acceleration level, the signal of the accelerometer 38 (Piezoelectric Ch...

Embodiment 2

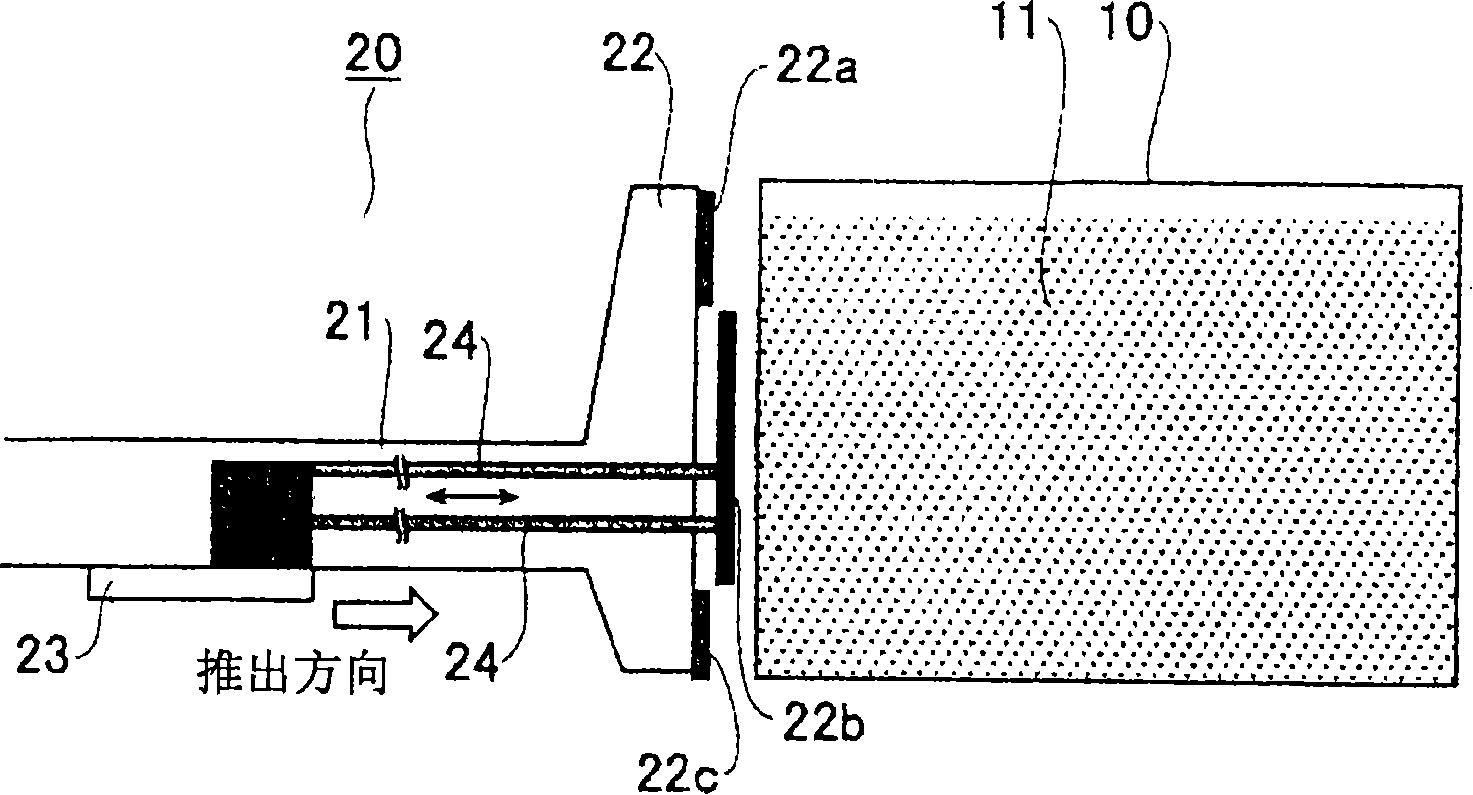

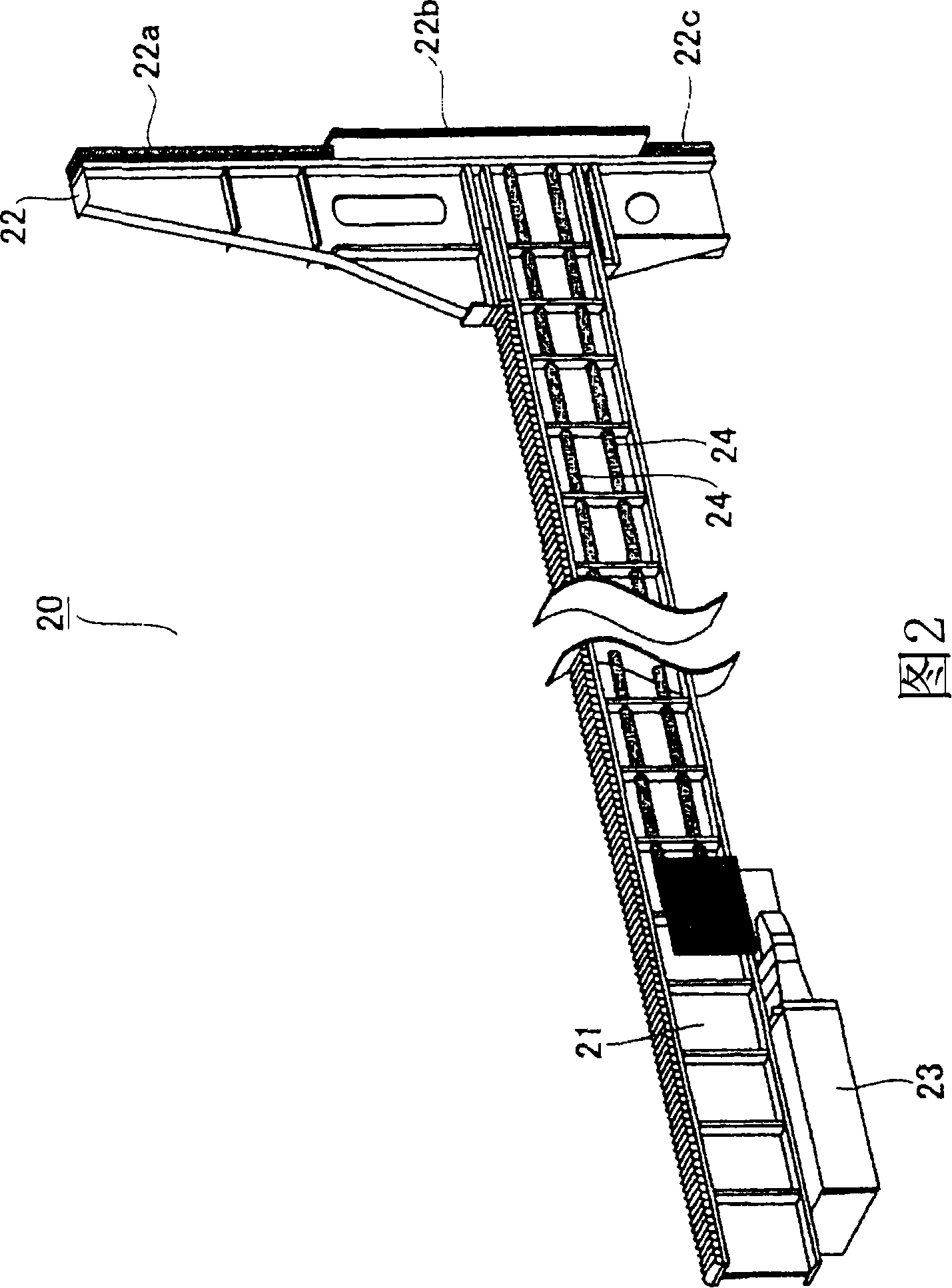

[0098] As the example of the present invention, in the actual coke oven type coke oven, use figure 1 , figure 2 The coke pushing device 20 shown pushes out the coke while giving vibration to the lump in the above-mentioned order. However, the measurement of the acceleration level was performed in the same manner as in Example 1.

[0099] Its vibration frequency is 40Hz, and the acceleration level is about 1G. In addition, in the blended coal used in the examples, the weighted average volatile content per batch was 27.2%, the weighted average expansion pressure per batch was 4.3 kPa, and the mixing rate of high expansion pressure coal was 17%. On the other hand, as a comparative example, similarly to the conventional method, pushing was performed without vibrating the block focus.

[0100] The push-out load ratio (relative ratio) in the example of the present invention and the comparative example is as follows image 3 As shown, in the example of the present invention, the...

Embodiment 3

[0103] As an example of the present invention, in an actual coke oven, use figure 1 and figure 2 The coke pushing device 20 shown pushes out the coke while giving vibration to the lump in the above-mentioned order. However, the measurement of the acceleration level was performed in the same manner as in Example 1.

[0104] Its vibration frequency is 50Hz, and its acceleration level is about 2G. Wherein, in the mixed coal used in the embodiment, the weighted average volatile component of each batch varies in the range of 24% to 31%, and the weighted average expansion pressure of each batch varies in the range of 4.1kPa to 7.2kPa, The effect of the invention of this application is adjusted by changing the mixing ratio of the high expansion pressure coal in the range of 11% to 26%. At this time, the temperature at the bottom of the combustion chamber of the coke oven was 1240° C., and the total carbonization time was 18 to 19 hours.

[0105] Figure 9 It shows the relations...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com