Intelligent heater for ironing plate of asphalt spreader

An intelligent heating and screed technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of large temperature difference, large electricity and gas consumption, deformation and other problems, and achieve the effect of uniform temperature, high thermal efficiency and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

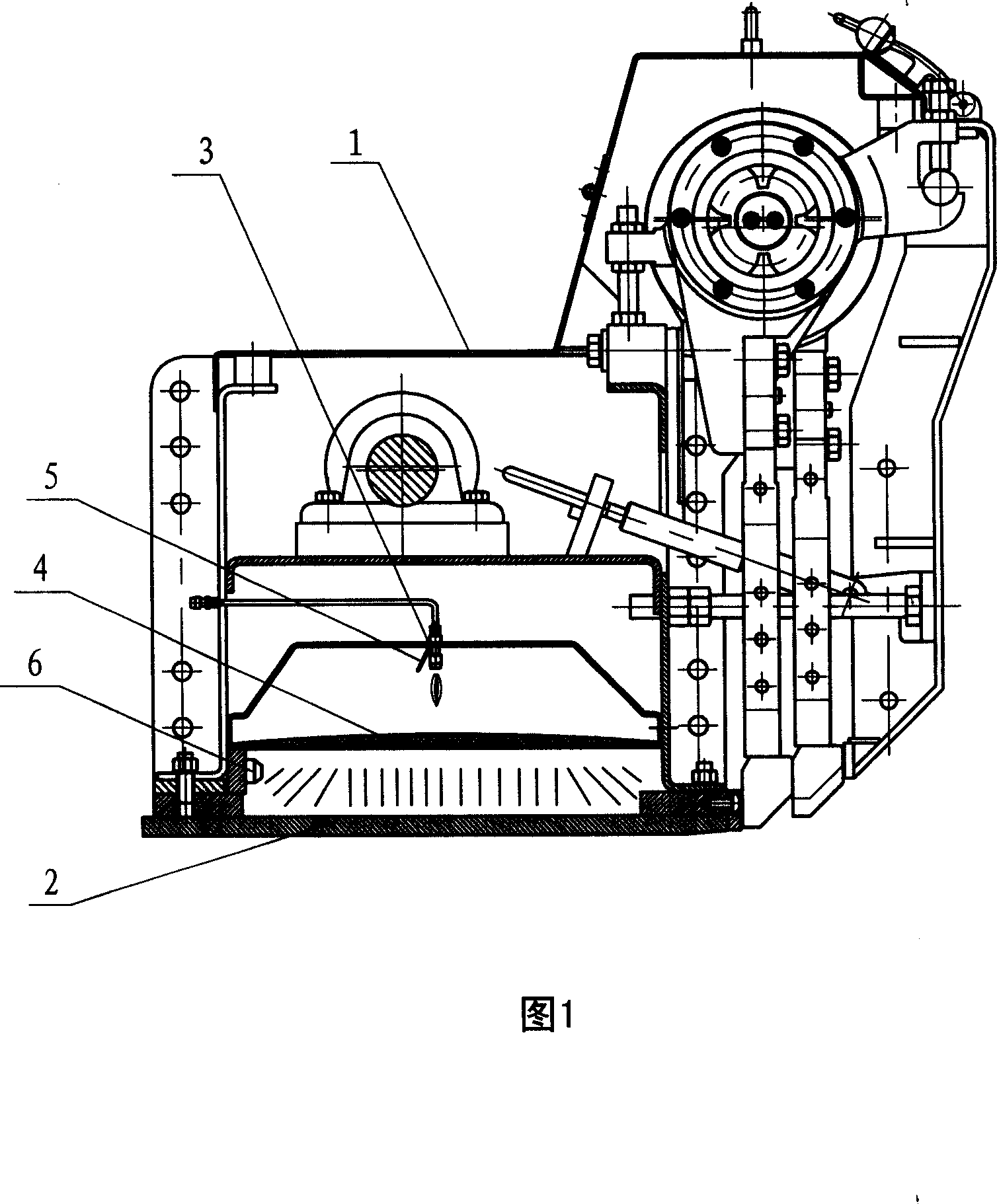

[0009] The intelligent heating device for asphalt paver screeds of the present invention includes multi-section screeds, the cross-section of each section of screeds is shown in Figure 1, and it includes a cover body 1 and a base plate 2, above the base plate in the cover body is provided with The burner nozzle 3, the burner nozzle is controlled by the combustion control system. A far-infrared radiation layer 4 made of a far-infrared radiation material is arranged between the burner nozzle and the bottom plate. A control needle 5 for detecting temperature is installed near the burner nozzle, and a temperature sensor 6 is arranged between the far-infrared radiation layer and the bottom plate.

[0010] As shown in Figure 2, the combustion control system includes a gas pipeline connected between the gas outlet and the burner nozzle 3, a manual gate valve 7 is installed at the beginning of the gas pipeline, and a pressure regulating valve 8 is installed behind the manual gate valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com