Simply corncob granule carbonization furnace and preparation method thereof

A corncob particle and carbonization furnace technology, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of complex carbonization furnaces and production processes, less porosity, and high hardness and strength of corncob carbon sticks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

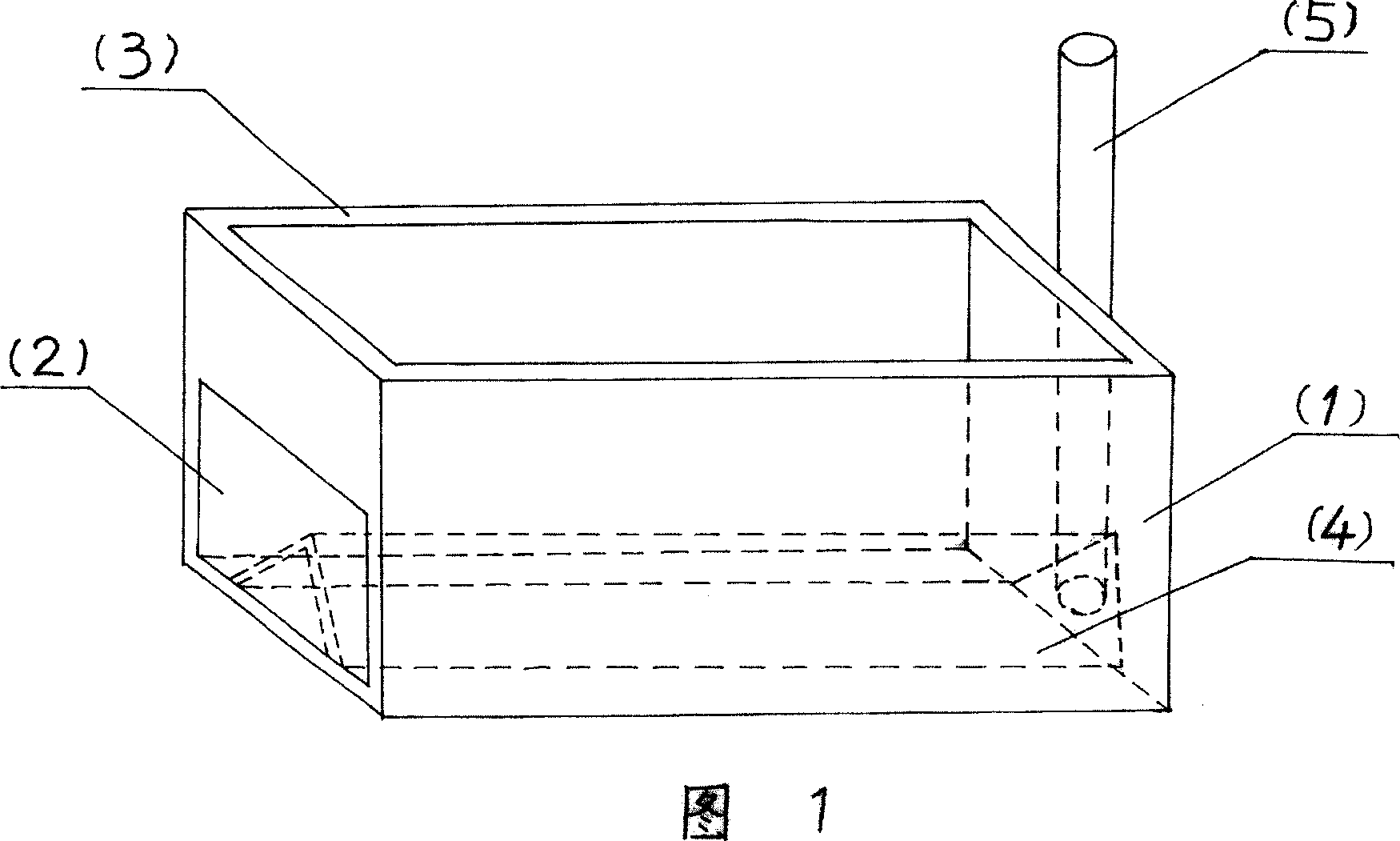

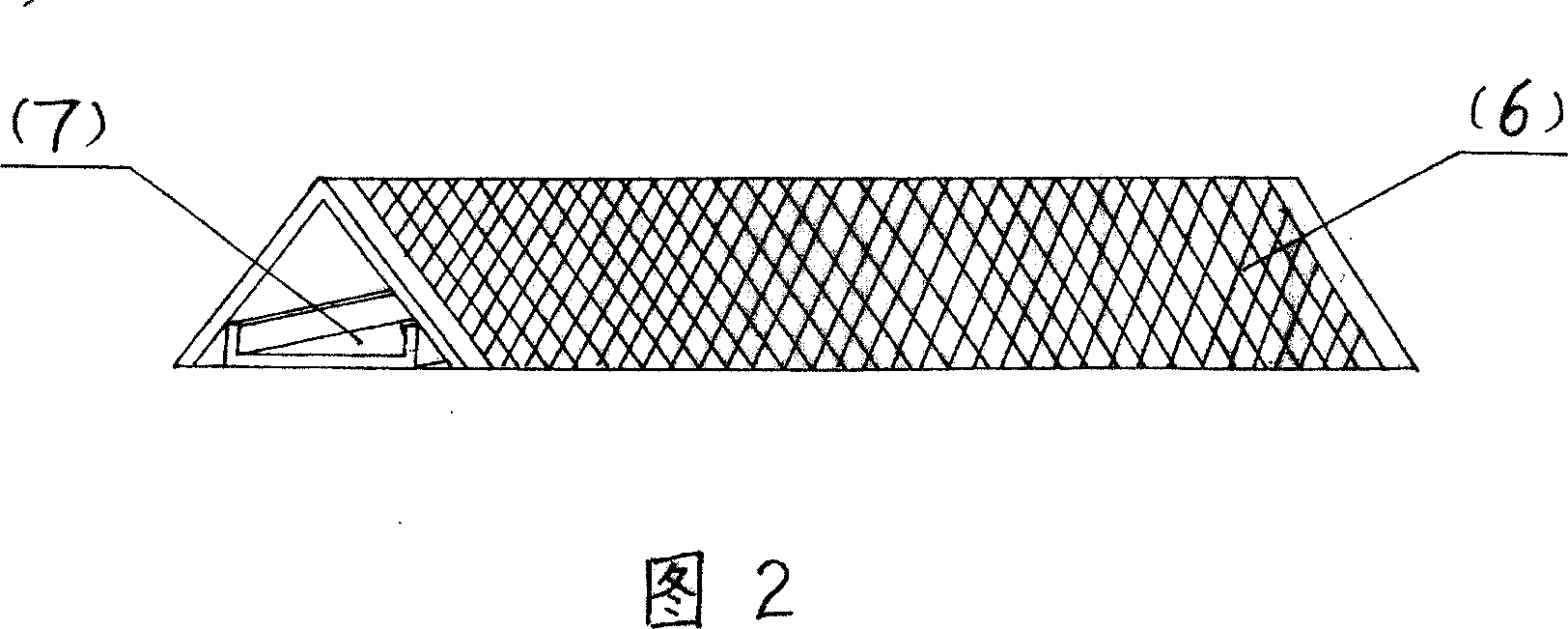

[0037] Example 1 Carbonization furnace

[0038] The carbonization furnace consists of a furnace body 1, a burner 4, an exhaust port 5, and a discharge port 2, as shown in Figure 1. In order to reclaim the wood vinegar discharged in the exhaust port 5, the exhaust port is connected with the water circulation gas condensation system to reclaim the wood vinegar. The body of the carbonization furnace is made of 8mm thick double-layer steel plate, and asbestos silk is used as the middle insulation interlayer. The furnace body is in the shape of a cuboid. The furnace body is semi-closed, with no cover on the top. The specific parameters of the special carbonization furnace for corncob granular carbon are shown in the table below. At the bottom of the narrower side of the furnace body 1, there is a discharge opening 2 for discharging and igniting the burner from the discharge opening. The outlet is square or semicircular. The size of the discharge port can be designed according ...

Embodiment 2

[0040] Example 2 Carbonization furnace

[0041] This embodiment is substantially the same as Embodiment 1, except that the furnace body is made of 6mm steel plate. The furnace body is cylindrical, and an exhaust port is provided on the opposite side of the discharge port. There is a mesh sliding door outside the discharge port. The burner is made of 3mm steel plate and is semi-cylindrical. The temperature controller is planted in the material in the furnace body. The outer dimension of the furnace body is reduced by one time according to the ratio of embodiment 1.

Embodiment 3

[0042] Example 3 Carbonization Furnace

[0043] This embodiment is substantially the same as Embodiment 1, except that the furnace body is made of 10mm steel plate. The furnace body is in the shape of a cube. The discharge port is triangular, and there is a plate type side sliding door outside the discharge port. An exhaust port is arranged on the side of the discharge port, and the exhaust pipe is in the shape of a triangular column. The burner is made of 7mm steel plate and is semi-cylindrical. The outer dimensions of the furnace body are doubled according to the ratio of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com