Oil gas and water mixed flow phase-splitting contimuous measuring equipment

A metering device, oil, gas and water technology, applied in the direction of volume flow measurement device, measuring device, liquid/fluid solid measurement, etc., to achieve the effect of wide viscosity range, stable measurement, stable and reliable long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For further disclosing the technical scheme of the present invention, below in conjunction, elaborate in detail through the embodiment;

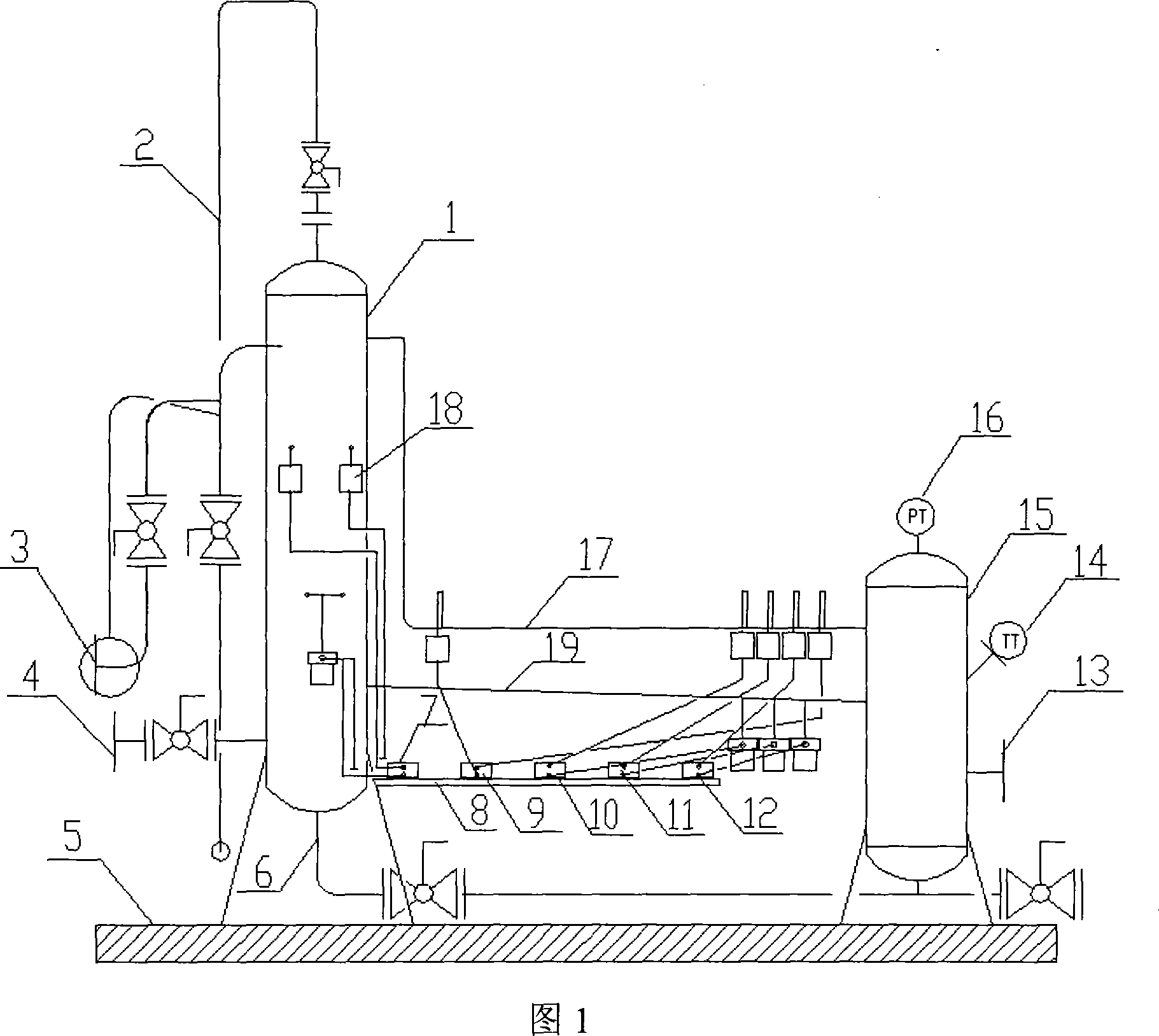

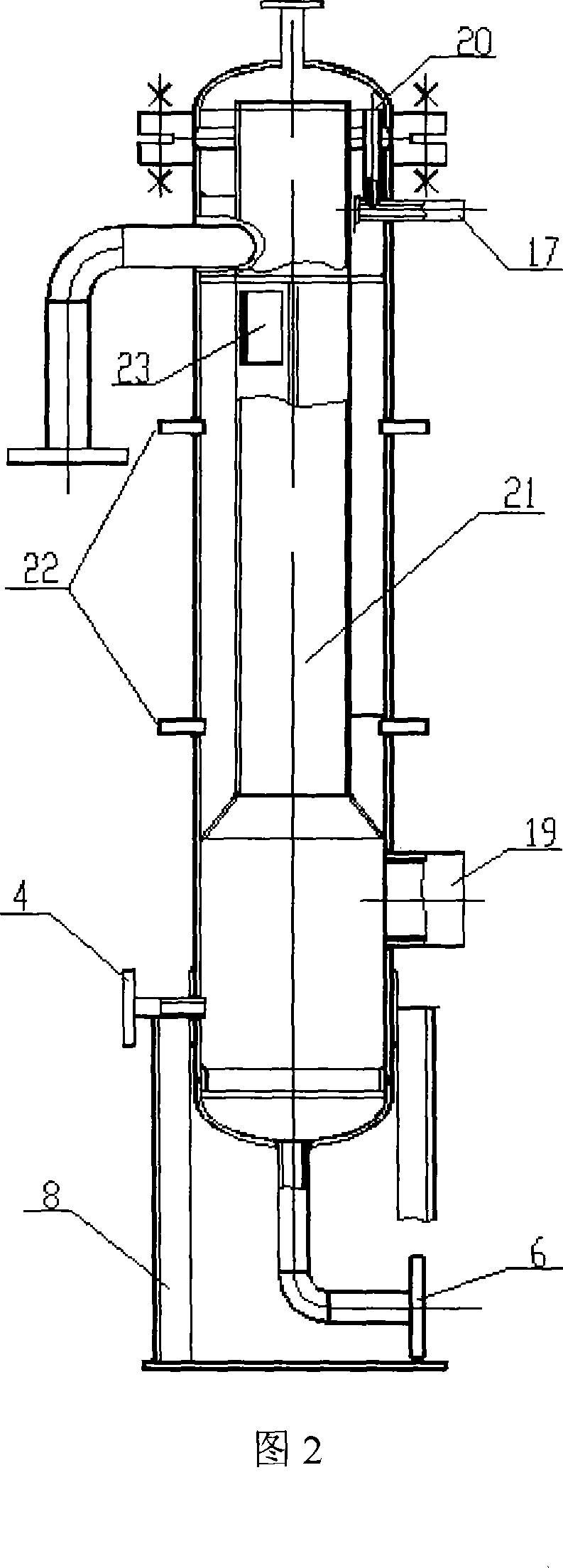

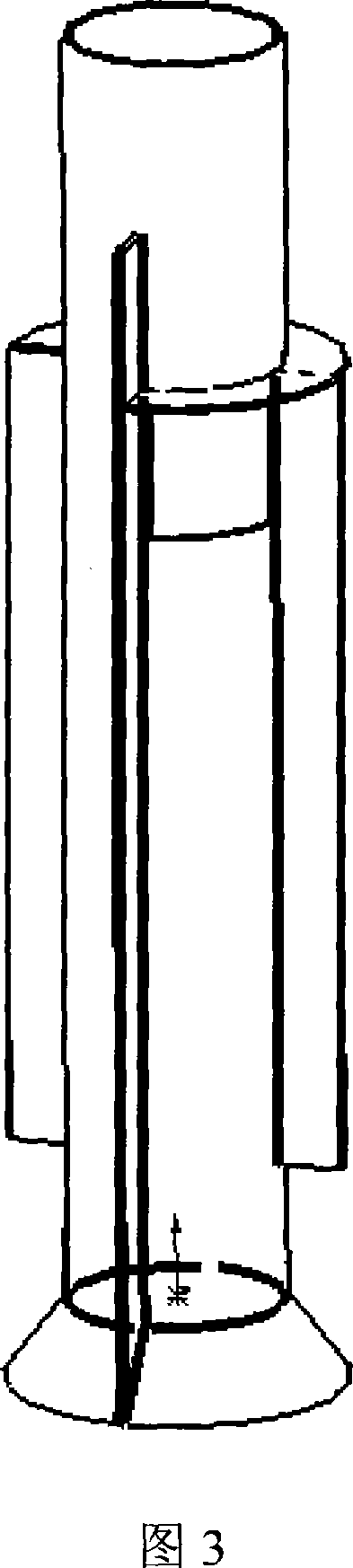

[0030] The invention relates to a multi-phase flow meter product that uses a new principle and method for high-precision, on-line continuous quantitative measurement. ), front tank (1), open channel inclined measuring tube (19), rear tank (15), gas differential pressure sensor (12), liquid level differential pressure sensor (9, 10, 11), pressure sensor (16), A temperature sensor (14) and a gas-liquid outlet (13) are formed. After the gas-liquid inlet, there is a cylindrical gas-liquid pre-separator cyclone (2). After the gas-liquid mixed flow is separated by the gas-liquid pre-separator (2), the gas flows from the top of the front tank through the pipeline at the upper end of the separator. Part of the gas flows into the rear tank through the gas bypass pipeline (17), and the other part of the gas flows into the rear tank through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com