Vapor deposition source and vapor deposition apparatus

A vapor deposition and steam technology, applied in lighting devices, light sources, electric light sources, etc., can solve the problems of difficult flow through the flow path, unable to quickly reach the opening, etc., and achieve the effect of high-speed vapor deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

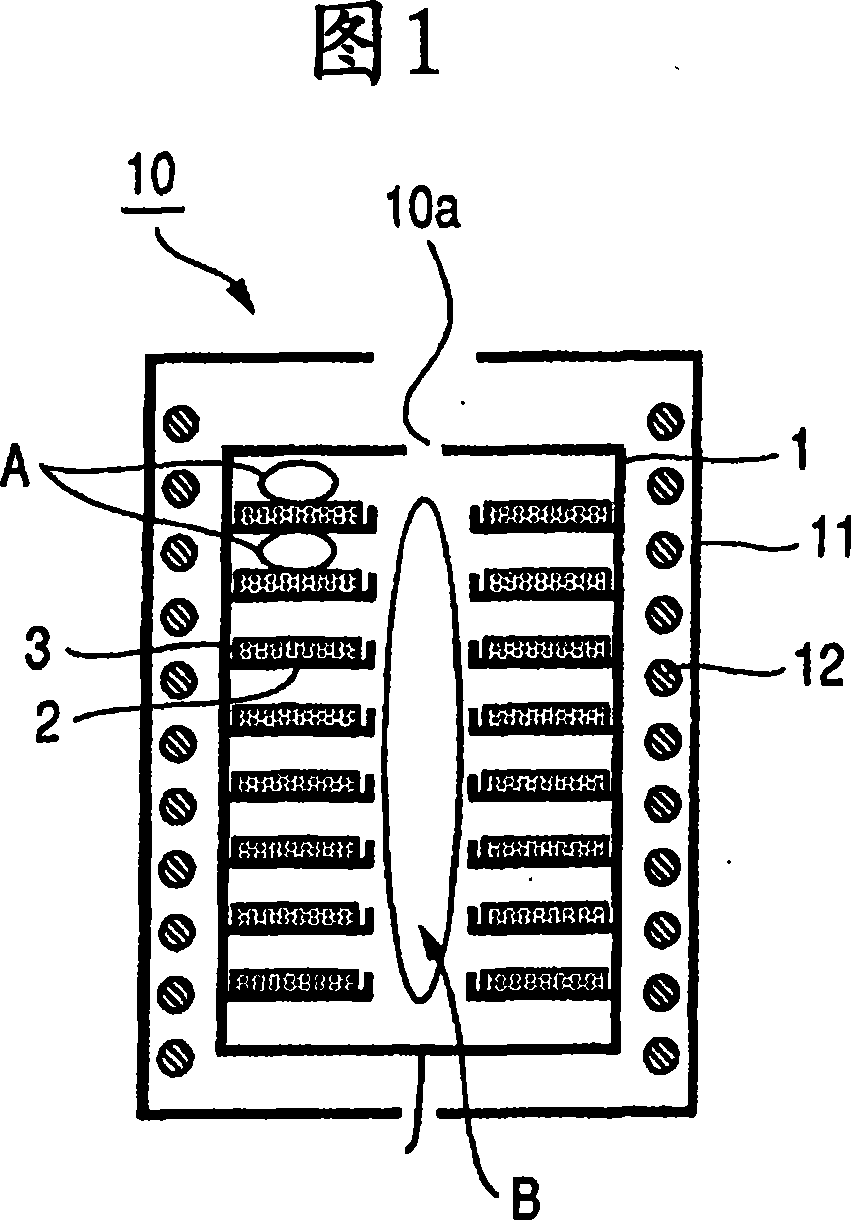

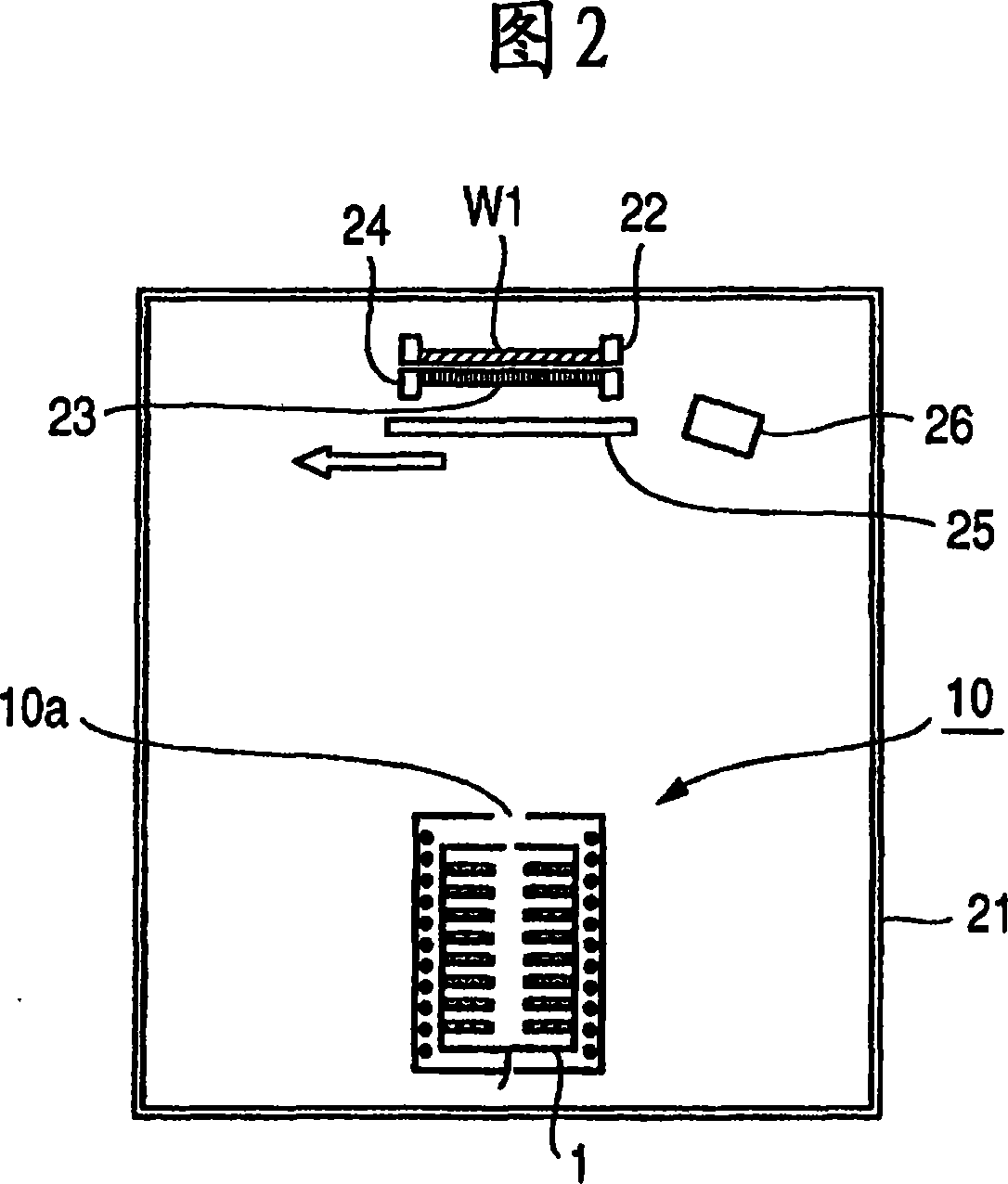

[0043] Fig. 1 shows a first embodiment, and a crucible 1 is supported by a structure (not shown) and heated by a heater 12 by radiation. The thermostat and power supply control the power of the heater 12 by using a thermocouple to measure the temperature of the bottom of the crucible 1 . The reflector 11 outside the heater 12 is used to concentrate the radiant heat from the heater 12 onto the crucible 1 . A thin vapor deposition material 3 is mounted on a donut-shaped plate 2 protruding inwardly from the inner wall of the crucible 1 . Each of the donut-shaped plates 2 is separated by a fixed distance from the adjacent upper and lower donut-shaped plates 2 .

[0044] In this embodiment, a 1 mm thick vapor deposition material 3 is mounted on each of the donut-shaped flat plates 2 . Each donut plate 2 has a diameter of 40 mm and a central circular hole with a diameter of 10 mm. Eight donut-shaped flat plates 2 are stacked coaxially with a distance of 5 mm. The flow space A be...

no. 2 example

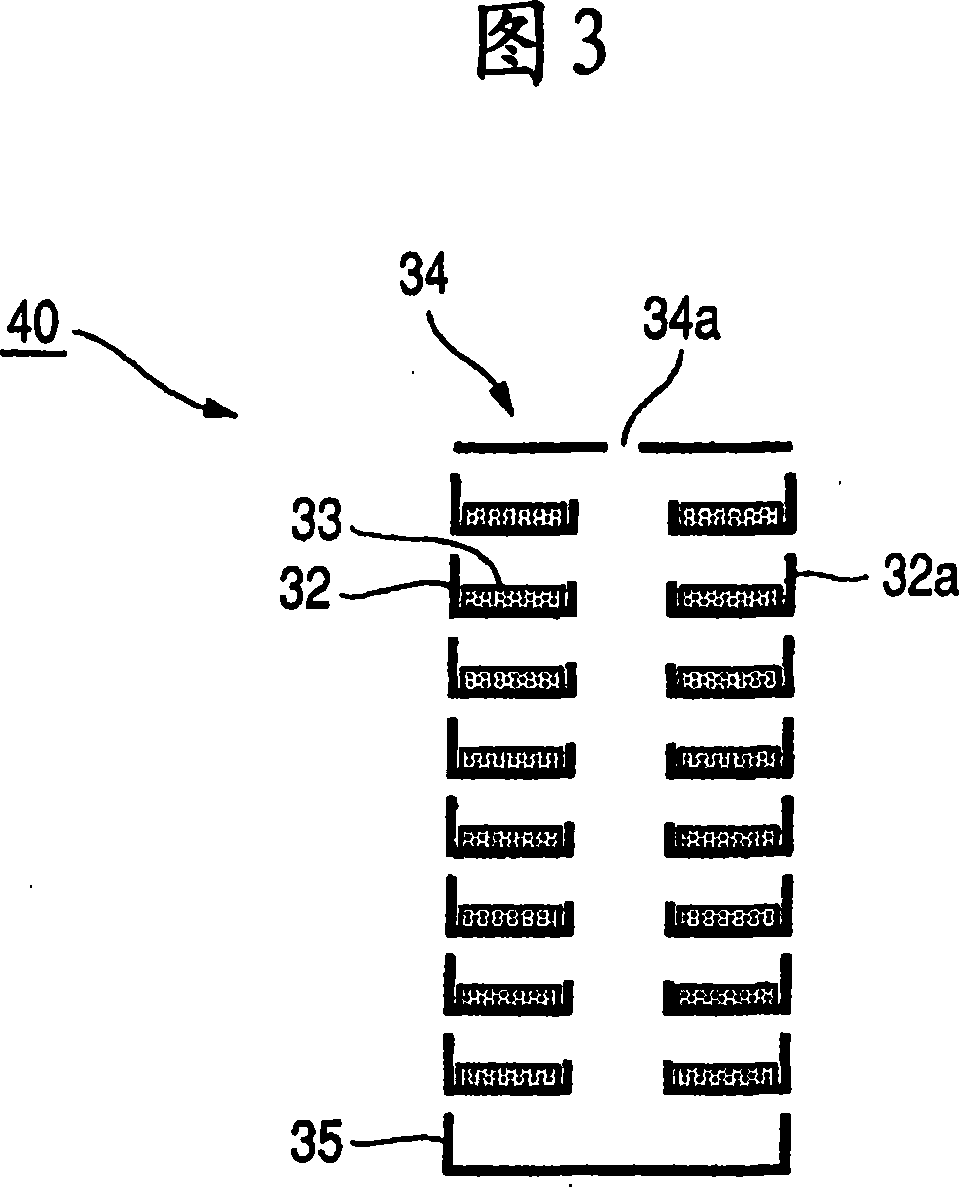

[0053]3 and 4 show a vapor deposition source 40 according to a second embodiment. As shown in the enlarged view of FIG. 3, each donut-shaped flat plate 32 of the vapor deposition source 40 has a side wall 32a, and the donut-shaped flat plate 32 integrated with the side wall 32a is individually provided on each layer. . Alq3 was mounted as a vapor deposition material 33 on a donut-shaped flat plate 32 coaxially stacked as shown in FIG. 4 . Then, a top cover 34 having a central hole 34a is provided on top, and a bottom plate 35 is provided on the bottom. The side wall 32a, the top cover 34 and the bottom plate 35 of the stacked donut-shaped flat plate 32 are adjusted so that they have the same function as the crucible 1 in the first embodiment, and then, the heater 42 is arranged outside the side wall 32a . That is, the vapor deposition source shown in FIG. 4 is adjusted so that a plurality of structures are stacked vertically in which the frame body is integrated with the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com