Dextroglucose plants organic nutrient solution and producing technique

A production process and dextrose technology are applied in the field of dextrose plant organic nutrient solution and production process thereof, and achieve the effects of good chelation tolerance, good water solubility and high organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

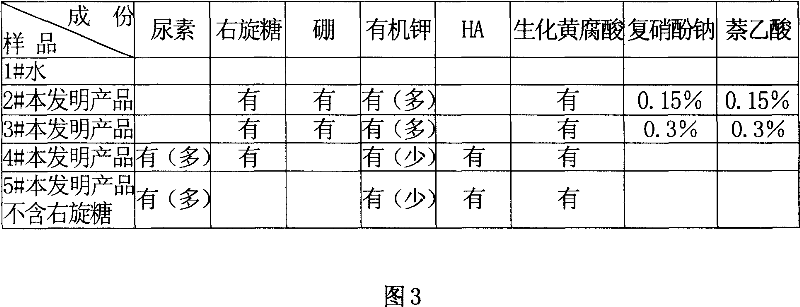

Image

Examples

Embodiment approach 1

[0072] Embodiment 1 of the production process of the present invention is as follows:

[0073] (1) Dissolution reaction: Take tap water and add it to the reaction kettle, slowly add industrial grade potassium hydroxide under stirring. Control the amount of potassium hydroxide added so that the dissolution temperature is below 50°C.

[0074] (2) Neutralization reaction: Slowly add food-grade citric acid to neutralize the reaction. The reaction temperature is controlled between 65 and 75°C, and the reaction is conducted for 45 to 60 minutes to generate potassium citrate.

[0075] (3) Mixing and dissolving: When the temperature drops below 60°C, add urea and stir to dissolve. Dissolving urea utilizes the heat of pre-reaction.

[0076] (4) Chelation reaction: at room temperature, add biochemical fulvic acid solution for chelation reaction for 15±5 minutes. After adding the biochemical fulvic acid solution, the reaction temperature is low, which can ensure the activity and nutrition of...

Embodiment approach 2

[0086] Embodiment 2 of the production process of the present invention is as follows:

[0087] (1) Dissolution reaction: Take tap water and add it to the reaction kettle, slowly add industrial grade potassium hydroxide under stirring. Control the amount of potassium hydroxide added so that the dissolution temperature is below 50°C.

[0088] (2) Neutralization reaction: Slowly add food-grade citric acid to neutralize the reaction. The reaction temperature is controlled between 65 and 75°C, and the reaction is conducted for 45 to 60 minutes to generate potassium citrate.

[0089] (3) Mixing and dissolving: When the temperature drops below 60°C, add urea and stir until it dissolves to obtain I solution.

[0090] (4) Dissolution reaction: Take tap water and add it to another reaction kettle, add 80% biochemical fulvic acid powder under stirring, and stir until completely dissolved to obtain II solution.

[0091] (5) Chelation reaction: Add solution II to solution I and stir for 15 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com