Thin plastic pipe machine for brushing

A technique for plastic pipes and brushing machines, which is applied to coatings, devices for coating liquid on surfaces, special surfaces, etc. It can solve the problems of unguaranteed quality of brushing, high labor intensity, and low efficiency of manual brushing. Improve the efficiency of brushing operations, fast and convenient loosening, compact and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

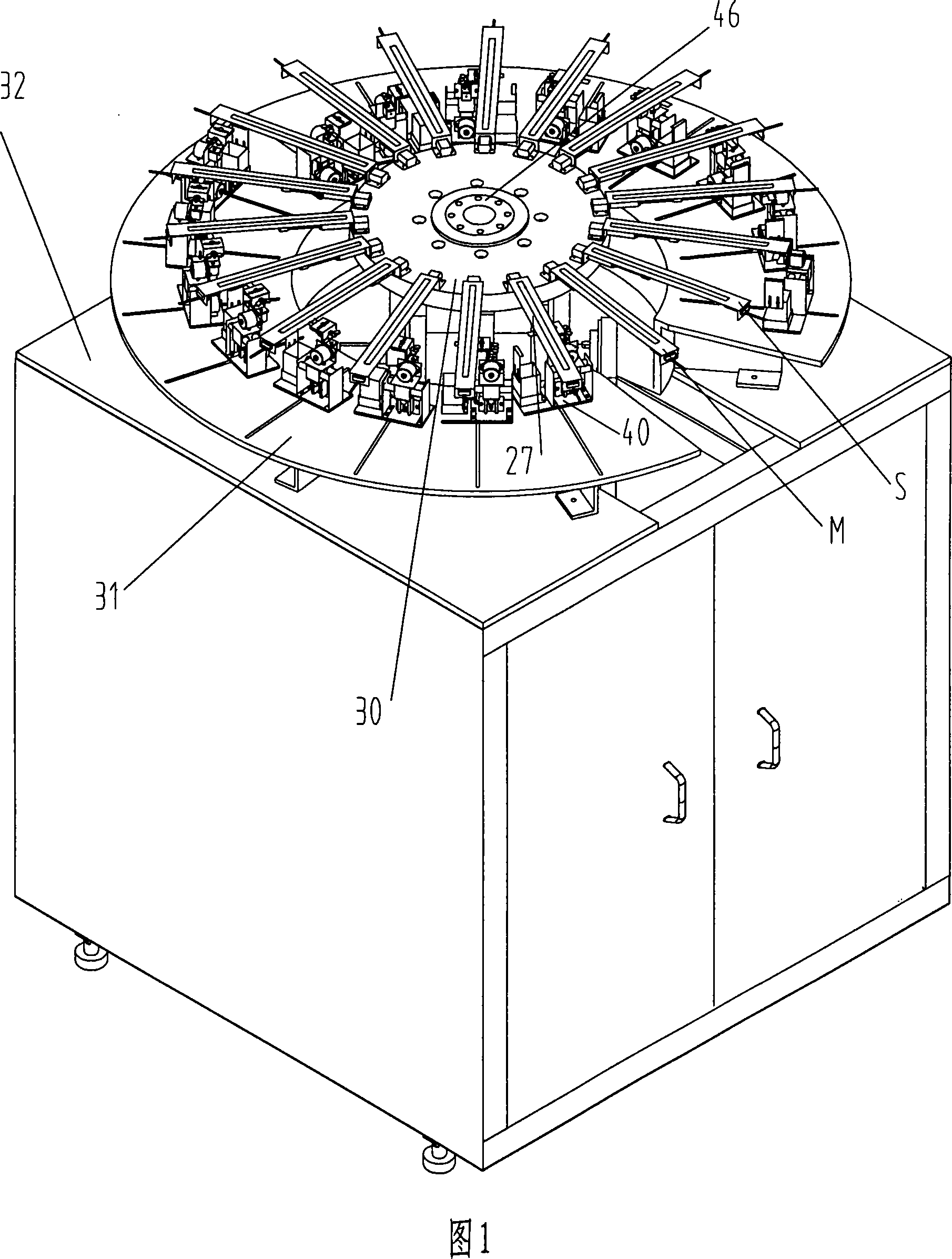

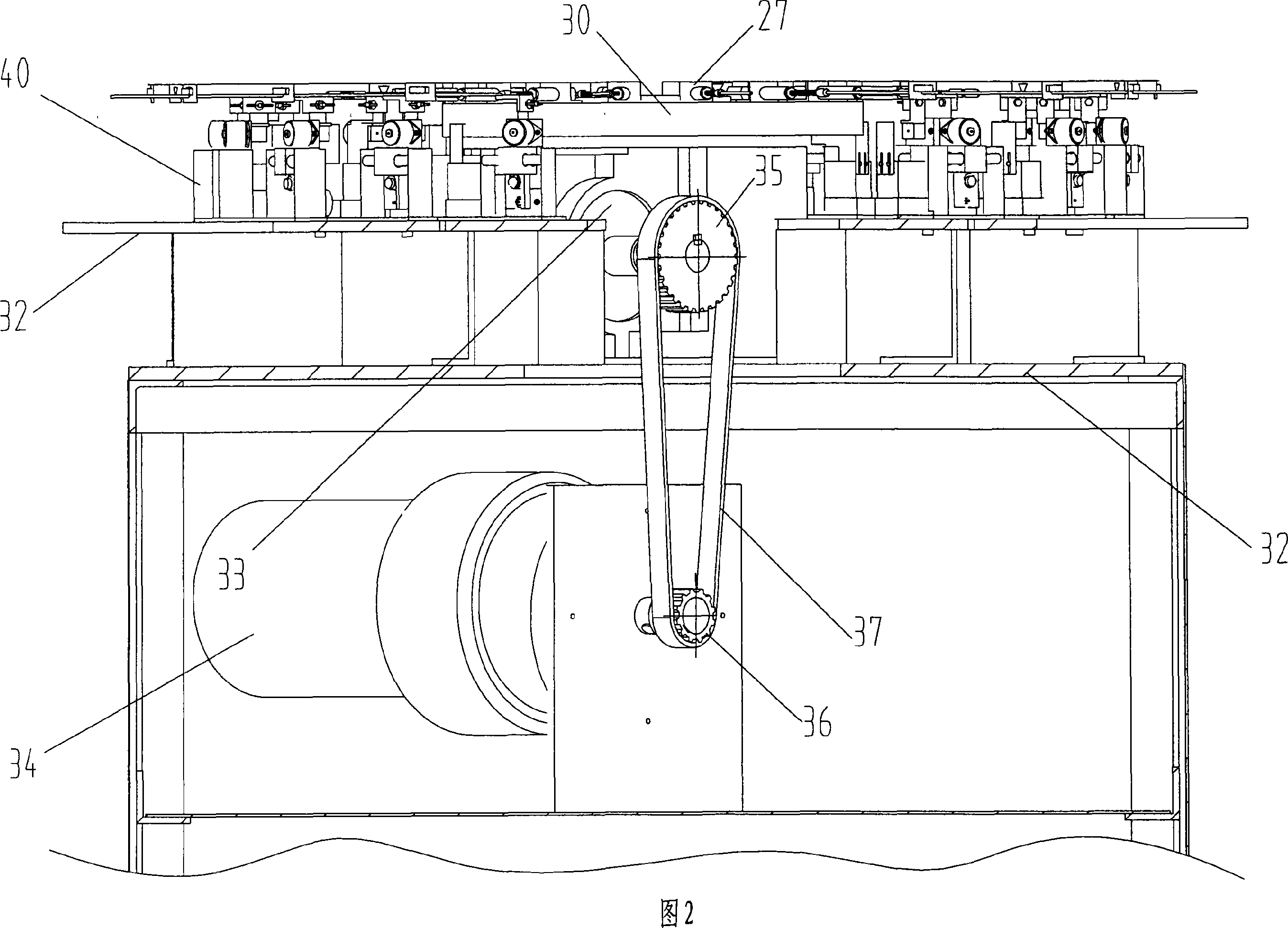

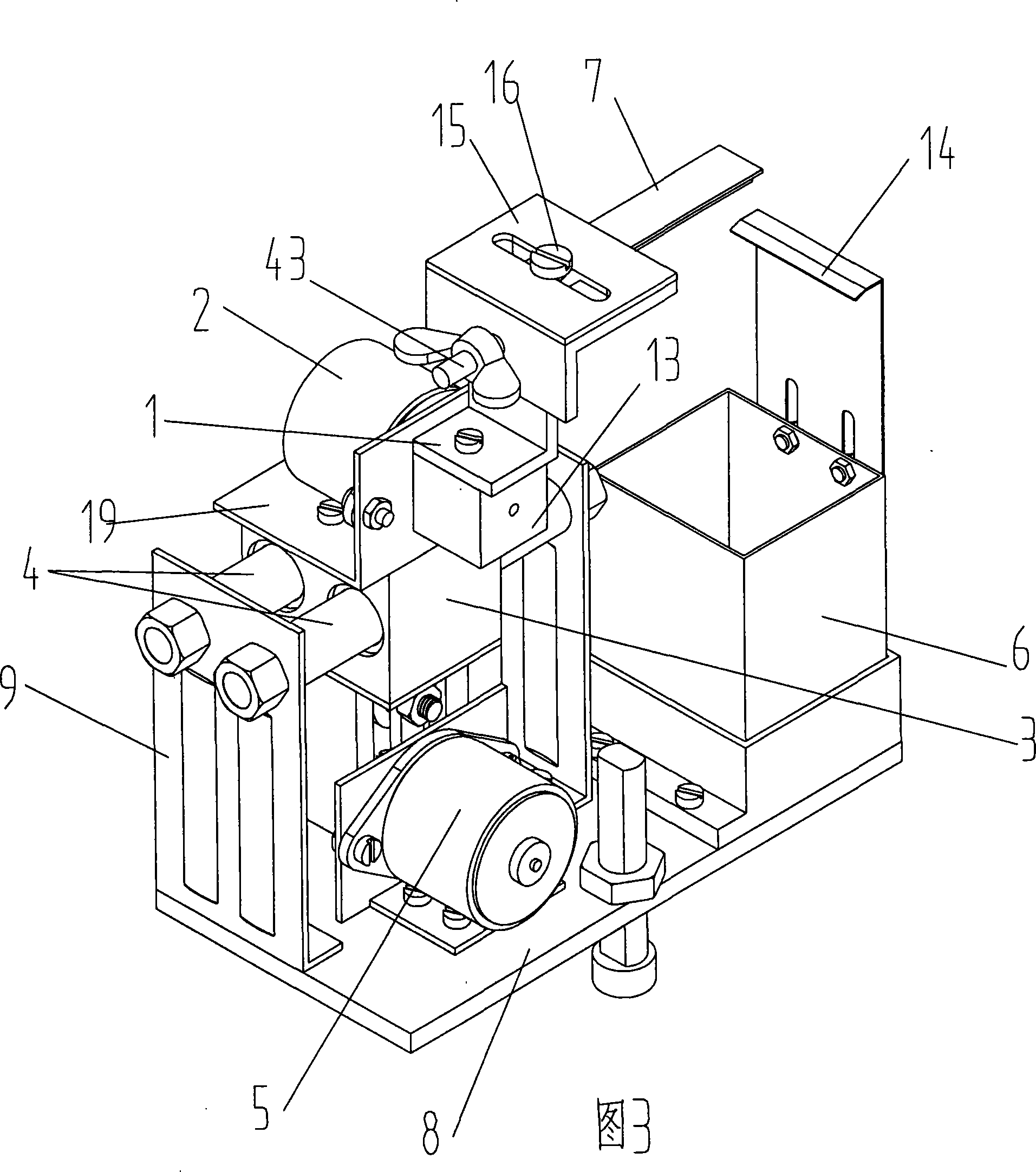

[0036] See Figures 1, 2, 3, 4, 5. The basic composition of the present invention has manipulator 40, clamping device 27 and workbench, and manipulator 40 is used for simulating human hands to finish dipping in paint, lifting, brushing, back pulling etc. in sequence; Pipe 38 and drive it to rotate, and the workbench is used to place the manipulator and the clamping device.

[0037] See Figures 6 and 7. The clamping frame 20 in the clamping device 27 is a horizontally arranged strip frame, the chuck motor 22 is fixed on its inner end, the tail end of the spring chuck 21 is connected with the output shaft of the chuck motor 22, and the front end of the shrapnel clips The hole 23 is a trumpet hole formed by a plurality of shrapnels, so that the ferrule 24 moves backward against the thrust of the compression spring 42, and the thin plastic tube 38 can be inserted into the shrapnel clamping hole 23, and then the ferrule 24 moves back under the action of the compression spring 42. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com