Combined compression and shearing process for the production of a crushed polyolefin foam and product obtained thereby

A polyolefin-based resin and technology for a manufacturing method are applied in the manufacture of polyolefin-based resin cross-linked foamed sheets and the fields of polyolefin-based resin cross-linked foamed sheets, and can solve the problems of poor production efficiency, complex cross-linking, poor flexibility, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0105] Low-density polyethylene (melt flow rate: 4.0g / 10 minutes, density: 0.923g / cm 3 ), ethylene-vinyl acetate copolymer (melt flow rate: 1.3g / 10 minutes, density: 0.930g / cm 3 , vinyl acetate content: 14% by weight), linear low-density polyethylene (melt flow rate: 6.0g / 10 minutes, density: 0.919g / cm 3 , α-olefin: 1-hexene), ethylene-propylene random copolymer (melt flow rate: 2.2g / 10 minutes, density: 0.92g / cm 3 , ethylene content: 3.6% by weight), azodicarbonamide, zinc stearate, calcium stearate, active zinc white, phenolic antioxidant (manufactured by Chiba Specialty Chemical Co., Ltd., trade name "Iruganox 1010") , trimethylolpropane trimethacrylate were supplied to the extruder according to the specified amount shown in Table 1, melted and kneaded at 135-140°C, and extruded from the extruder to have the thickness shown in Table 1. Expandable polyolefin-based resin sheet (in Table 1, only indicated as "expandable resin sheet"). In addition, the width of the foamable ...

Embodiment 7

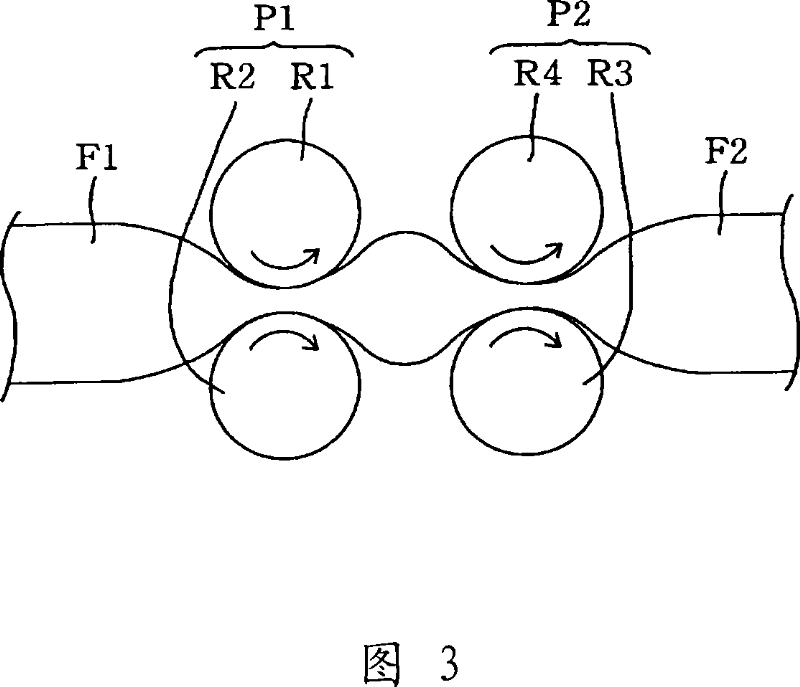

[0130] As shown in FIG. 3 , prepare a manufacturing device having a group of rolls including: a pair of rolls P1 consisting of a pair of upper and lower rolls R1, R2, and a pair of upper and lower rolls R3 arranged in front of the pair of rolls P1. , P2 of paired rolls of R4. In addition, the distance between the opposing surfaces of the rollers R1 and R2 of the pair of rollers P1 was 0.15 mm, and the distance between the opposing surfaces of the rollers R3 and R4 of the pair of rollers P2 was 0.15 mm. The rolls R1 to R4 are cylindrical rolls having the same diameter. The rollers R1 to R4 all have the same diameter over the entire length in the longitudinal direction. The roller R1 and the roller R2 of the pair of rollers P1 are arranged such that their axial centers are parallel to each other. The roller R3 and the roller R4 of the pair of rollers P2 are arranged such that their axial centers are parallel to each other.

[0131] The peripheral velocity V3 of the roller R1 ...

Embodiment 8

[0138] A vertically expanded foam sheet F1 having independent cells comprising a polyolefin resin based on an ethylene-vinyl acetate copolymer was prepared. The foam sheet F1 with independent cells is composed of a foam layer and a skin layer, the foam layer substantially only contains independent cells, the skin layer is formed on both sides of the foam layer, and the cells of the foam layer The cell walls are airtightly adhered and integrated to form a thin film. And the foam layer and skin layer of the foam seat|seet F1 which has closed cells have the crosslinked structure obtained by electron beam crosslinking. The expansion ratio of the above-mentioned foam sheet F1 with independent cells is 30 times (density: 31kg / m 3 ), the thickness of the foam sheet F1 with independent cells is 5.2mm, the width of the foam sheet F1 with independent cells is 2m, and the average cell diameter of the independent cells of the bubble layer in the foam sheet F1 with independent cells is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com