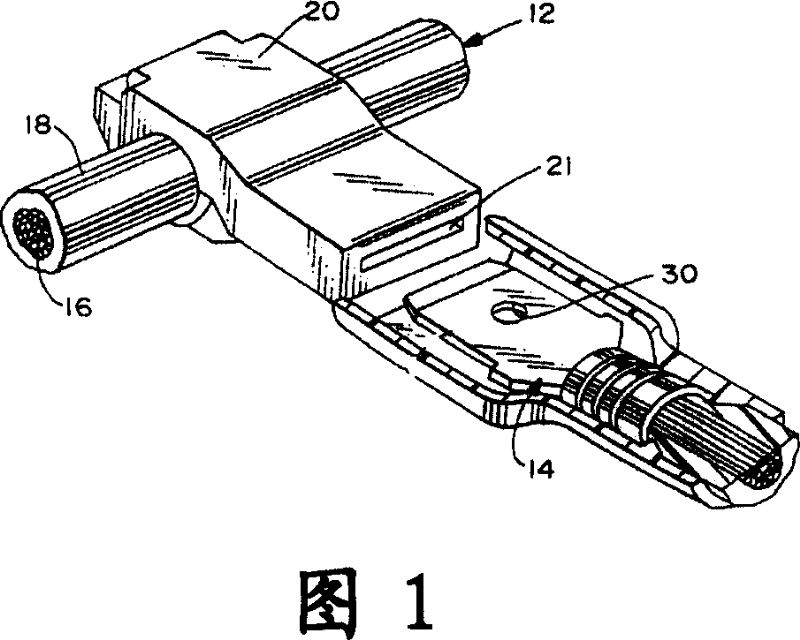

Electronic tap connecting element, assembly and insulation cover thereof

A technology for connecting components and electronics, applied in the manufacturing of electrical components, connections, contacts, etc., can solve the problems of uneven force, reduced reliability of U-shaped connecting terminals 22, etc., to increase the service life and increase the current transmission capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

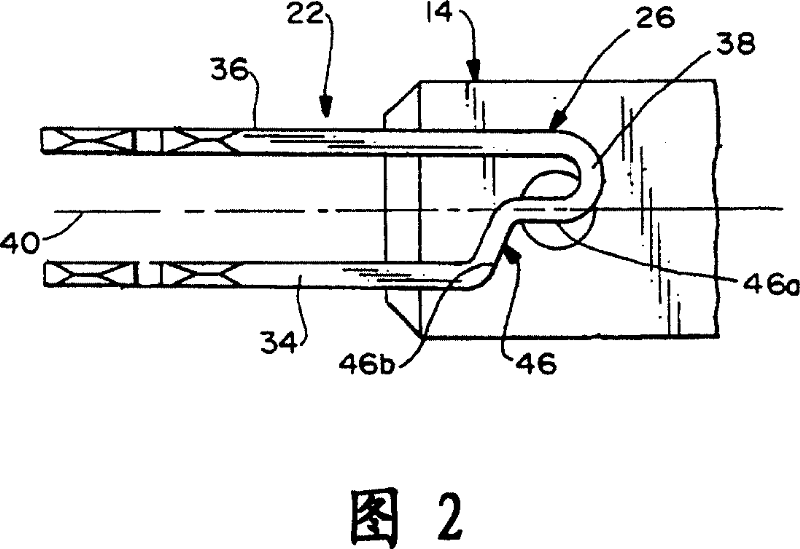

[0037] Since the present invention discloses a structure of an electronic tap connection component, the connection terminals formed by some stamping process technologies used therein and the combination of the connection terminals and the insulating housing (housing) have been disclosed in detail in the prior art , so in the following description, the related stamping process of the connection terminal and the combination process of the connection terminal and the insulating cover are not fully described. Moreover, the drawings in the following texts are not completely drawn according to the actual relevant dimensions, and their function is only to express the schematic diagrams related to the features of the present invention.

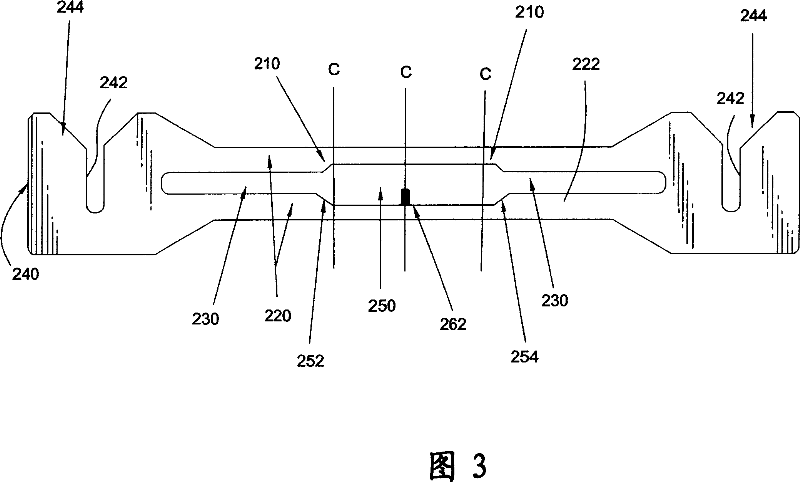

[0038] First of all, please refer to FIG. 3 , which is a thin metal plate structure produced by the stamping process of the present invention. The thin metal plate will form a similar W-shaped terminal 200 structure after proper processing. The thin m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com